Flow meter nominal capacity, Flow meter coefficient – Fill-Rite TS AA Mechanical Precision Meter User Manual

Page 4

1 . 4

TS Series, Anodized Aluminum - Specifications for V●● assemblies

Materials

Case : Anodized aluminum

Rotors : PPS with carbon bearings,

(oval gears)

Teflon

TM

bearings optional.

Posts : HC303SS

Seals : Viton

TM

standard,

Teflon

TM

optional.

Connections

Bolted companion flanges with NPT or BSP port;

Optional: Anodized

aluminum

welding

flanges

Carbon

steel

welding

flanges

Carbon

steel

150#

RF

ANSI

adaptors

Pressure Rating at 100°F (38°C) with 3:1 Safety Factor

Meter/Strainer

: 150 PSI/100°F = 10.3 BAR/40°C

Air Elim/Valves: 150 PSI/100°F = 10.3 BAR/40°C

Temperature Rating

V

assy

: -40°F to +180°F = -40°C to +80°C

Use HT or HV rotors if temp. can exceed 120°F = 50°F

Meter Performance

When field calibrated on actual liquid of service

Linearity

Over 5:1 turn-down from max. capacity : ±0.175%

Over 10:1 turn-down from max. capacity : ±0.30%

Over 30:1 turn-down from max. capacity : ±0.5%

Repeatability

0.05% or better under constant conditions

Nominal Capacity

With LV rotors on 1-300 cP viscosity:

With HV rotors on 5-1000 cP viscosity:

GPM LPM m

3

/h

TS10A 40 150 9

TS15A 60

230

14

TS20A** 150

570

34

TS30A** 200

760

45

** = On low viscosity lubricating liquids, intermittent

use to 125% of capacity is permitted.

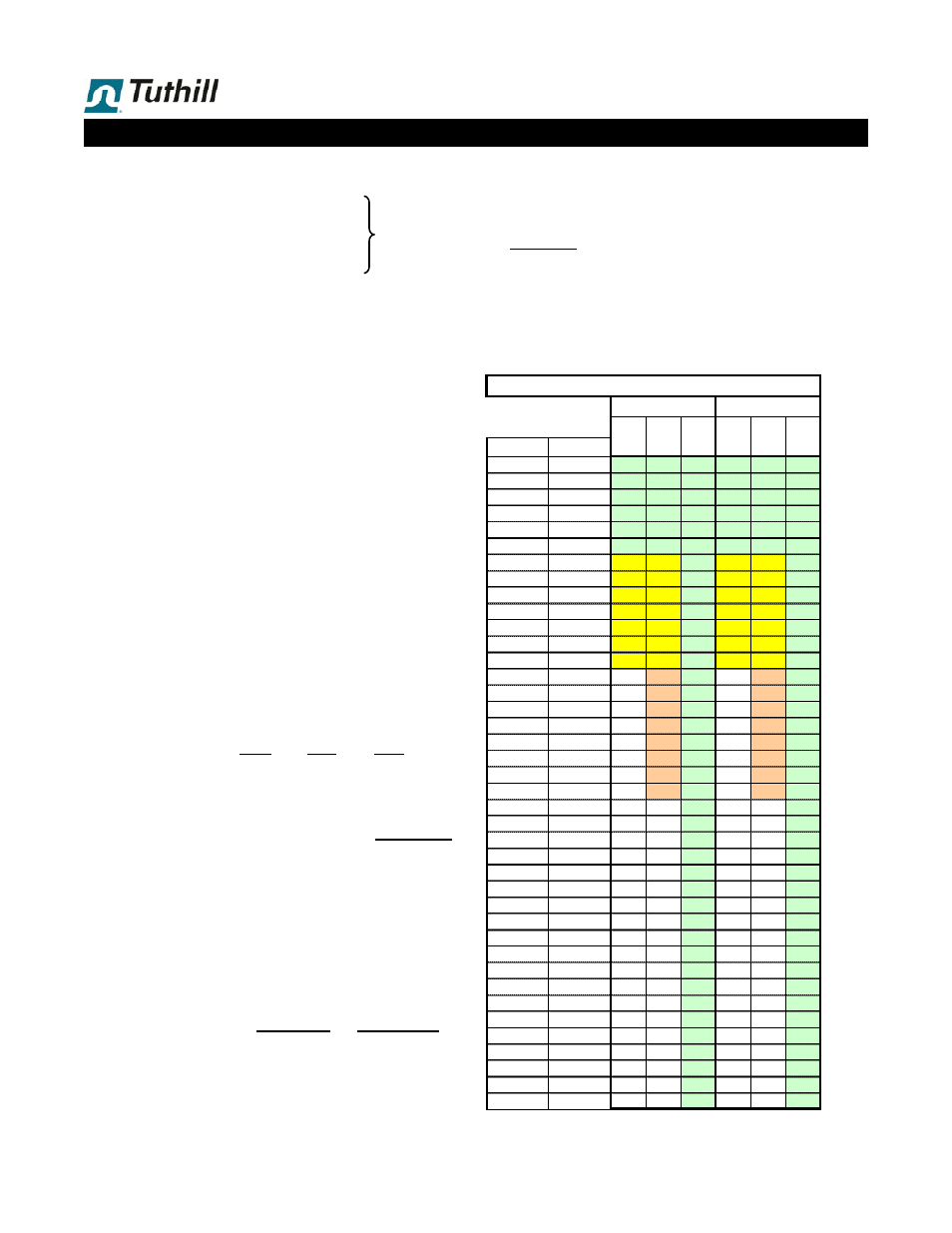

Viscosity

With LV rotors 100% capacity to 1,500 SSU/300 cP.

With HV rotors 100% capacity to 5,000 SSU/1,000 cP.

With HV rotors, the flow meter may be used to

1,500,000 SSU/350,000 cP at reduced flow rates (see

meter viscosity/coefficient table in next column).

Opt. Pulsers on mechanical register

10:1 pulser 100:1 pulser

1/10

gallon

register 10

PPG

100

PPG

Whole gallon register 1 PPG 10 PPG

1/10

liter

register

10

ppl

100

ppl

Whole liter register 1 ppl 10 ppl

Dekaliter

register 0.1

ppl

1

ppl

●

●

●

●

Rotor

B

L

I

C

M

J

Code

SSU

cSt

LV

HT

HV

LV

HT

HV

TYPE

32

1 1.00 1.00 1.00 1.00 1.00 1.00

60

10 1.00 1.00 1.00 1.00 1.00 1.00

240

50 1.00 1.00 1.00 1.00 1.00 1.00

465

100 1.00 1.00 1.00 1.00 1.00 1.00

925

200 1.00 1.00 1.00 0.90 0.90 1.00

1,415

300 0.86 0.86 1.00 0.73 0.73 0.98

1,890

400 0.77 0.77 1.00 0.62 0.62 0.96

2,360

500 0.71 0.71 1.00 0.57 0.57 0.94

2,830

600 0.66 0.66 1.00 0.53 0.53 0.92

3,300

700 0.63 0.63 1.00 0.50 0.50 0.90

3,775

800 0.60 0.60 1.00 0.48 0.48 0.85

4,250

900 0.56 0.56 1.00 0.45 0.45 0.80

4,720

1,000 0.54 0.54 1.00 0.43 0.43 0.75

9,440

2,000

0.35 0.77

0.28 0.65

14,150

3,000

0.28 0.65

0.22 0.55

18,875

4,000

0.24 0.58

0.19 0.46

23,600

5,000

0.19 0.53

0.15 0.42

28,325

6,000

0.16 0.49

0.13 0.39

33,050

7,000

0.14 0.47

0.11 0.37

37,750

8,000

0.12 0.44

0.09 0.35

42,475

9,000

0.10 0.42

0.08 0.34

47,200

10,000

0.41

0.32

94,400

20,000

0.30

0.24

141,600

30,000

0.24

0.19

188,800

40,000

0.20

0.16

236,000

50,000

0.18

0.14

283,200

60,000

0.17

0.13

330,400

70,000

0.14

0.11

377,600

80,000

0.13

0.10

424,800

90,000

0.12

0.10

472,000

100,000

0.11

0.09

944,000

200,000

0.08

0.06

1,416,000

300,000

0.07

0.05

1,888,000

400,000

0.06

0.05

2,360,000

500,000

0.06

0.04

2,832,000

600,000

0.06

0.04

3,304,000

700,000

0.05

0.04

3,776,000

800,000

0.05

0.04

4,248,000

900,000

0.05

0.04

4,720,000 1,000,000

0.05

0.04

Intermittent service = < 6 hours/day,

and deliveries not to exceed 15-20 minutes.

On higher viscosity liquids,

model nominal capacity is

reduced

as per tables below .

Liquid Viscosity

Flow Meter Coefficient

Carbon brgs. Teflon brgs.

Normal operating range is w ith 10:1 turn-dow n from model

nominal capacity.

Flow Meter

nominal capacity

:

On low viscosity liquids, best performance (linearity/service life)

is betw een 50% and 85% of model nominal capacity.

On diesel fuel, TS20A & TS30A models w ith mechanical

register only may be operated to 125% of nominal capacity in

intermittent service

(this does NOT apply to models with

preset and/or printer).

See cover for

rotor & seal

materials in

this meter.