General instructions for assembling the antenna, Torque specifications – Hughes AN6-098P User Manual

Page 40

Chapter 3 • Assembling the antenna

22

1037312-0001 Revision A

In this manual, installation software refers to installation,

pointing, and commissioning software accessed through the IDU,

which works in conjunction with SBC.

Before proceeding, use the installation software to determine the

initial values to use for setting azimuth, elevation, and

polarization. Record these values and keep them handy for

reference as you install and point the antenna. To use the

installation software, follow the instructions in the IDU

installation manual for commissioning the IDU.

General instructions for

assembling the antenna

Before you assemble the antenna, read these important

instructions:

• Mast – The mast must be installed before you can install the

antenna. For information on antenna mounting methods, see

the HN System Antenna Site Preparation and Mount

Installation Guide (1035678-0001). The mast must have an

outside diameter of 2-

3

⁄

8

inches (2.375 inches).

• Sequence of steps – When you assemble the antenna, follow

the instructions in this chapter in the order they are

presented.

• Tightening hardware– Do not tighten any nuts or other

hardware until you are instructed to do so. (See also the next

item, Torque.)

• Torque – To ensure successful installation of the antenna, you

must tighten all nuts and socket-head cap screws to the

maximum torque values shown in Table 6. This is a critical

requirement.

For bolts that use a split lock washer, tighten the bolt until the

washer is flattened, but do not tighten the bolt further. When

the washer is flattened, this indicates that sufficient torque

has been applied.

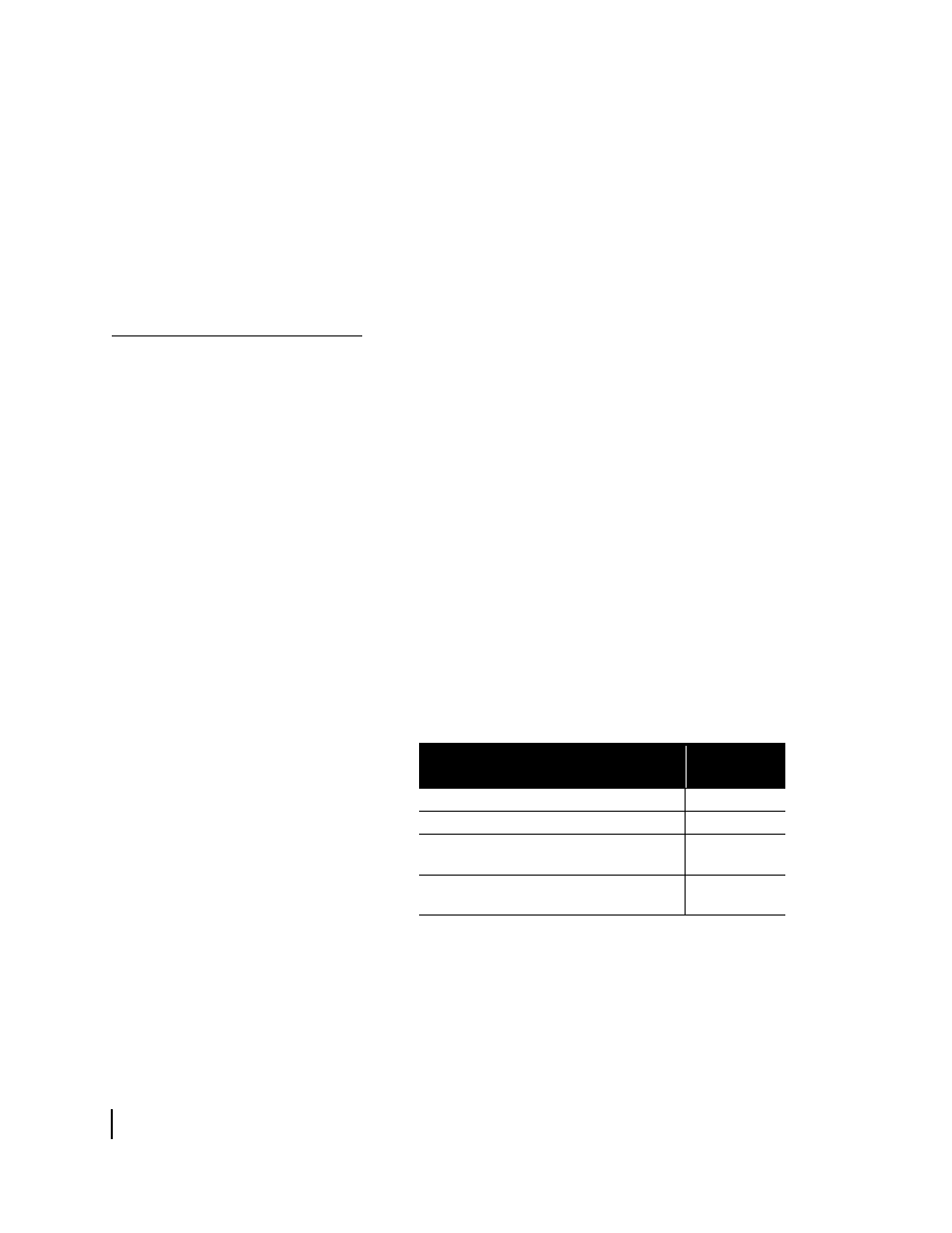

Table 6: Torque specifications

Fastener

Maximum

torque

¼-inch bolts

6 ft-lb

5/16-inch bolts

15 ft-lb

¼-20 thread-cutting screws used to

secure reflector bracket to reflector

10 ft-lb

No. 6-32 and M4 socket-head cap

screws

15 inch-lb