Figure 23 outdoor fan/condenser configuration, 7 water/glycol cooled condensers, Coaxial condenser – Emerson Liebert Challenger With Liebert iCOM Control 3000/ITR User Manual

Page 49: Water/glycol cooled condensers

Component Operation and Maintenance

43

Checking Refrigerant Charge (Lee–Temp/Flood Back Head Pressure Control)

The system refrigerant level must be checked periodically. To do so:

1. Adjust temperature setpoint in the unit so that the compressor will run continuously.

2. The refrigerant level is visible through two sight glasses on the receiver and will vary with

ambient temperature.

a. 40°F (4.4°C) and lower — Midway on the bottom sight glass.

b. 40 to 60°F (4.4 to 15.6°C) — Bottom sight glass should be clear with liquid.

c. 60°F (15.6°C) and above — Midway on the top sight glass.

3. Return temperature setpoint to desired number.

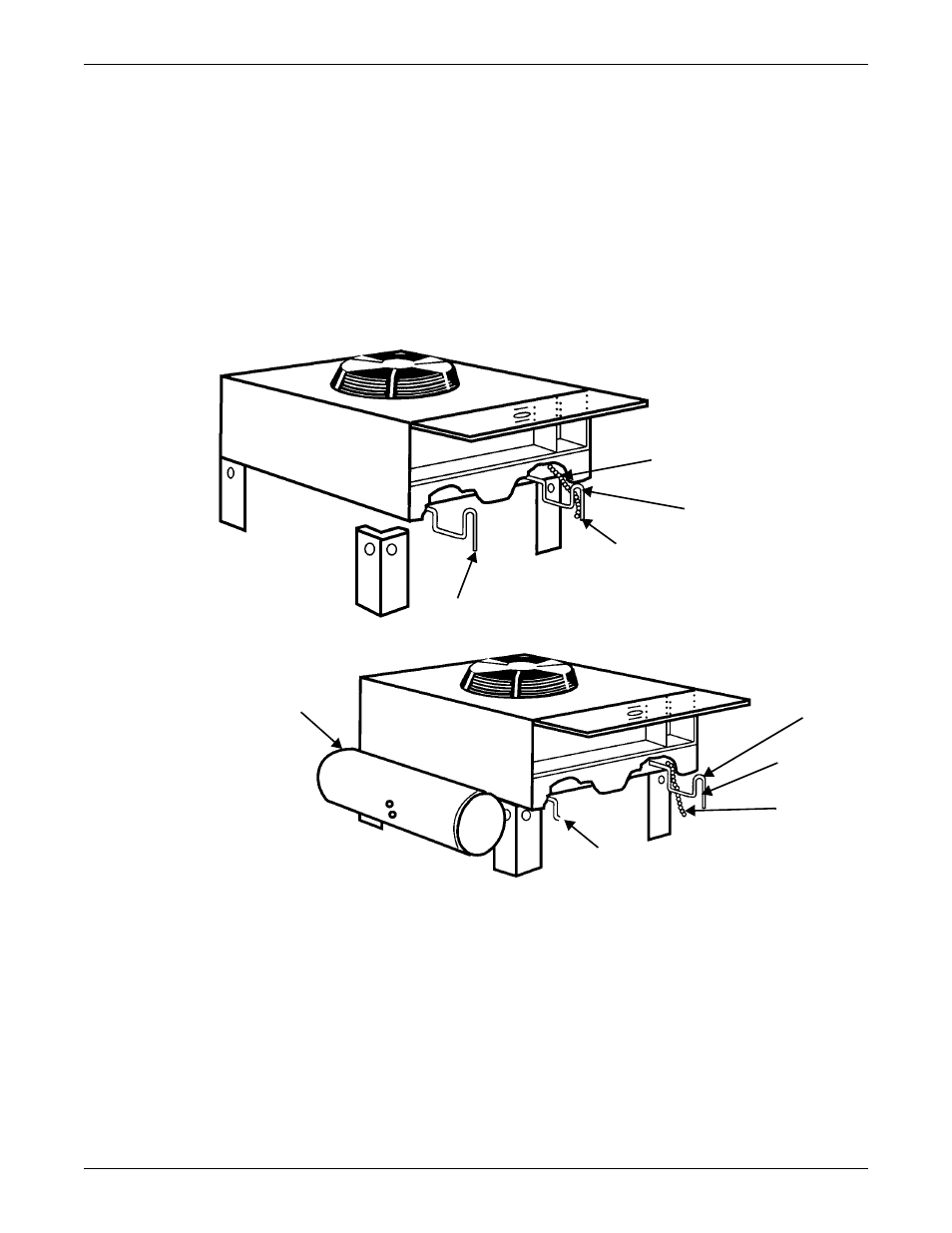

Figure 23 Outdoor fan/condenser configuration

7.4.7 Water/Glycol Cooled Condensers

Coaxial Condenser

Each water- or glycol-cooled module has a coaxial condenser that consists of a steel outside tube and a

copper inside tube.

Coaxial condensers do not normally require maintenance or replacement if the water supply is clean.

If your system operates at high head pressure with reduced capacity, and all other causes have been

eliminated, the coaxial condenser may be obstructed and needs to be replaced.

Secure each leg to condenser

frame at all points shown using

hardware provided.

Liquid line

* B

Hot gas line

Electric service

supplied by others

FAN SPEED CONDENSER

Lee-Temp heater pad

connection box

*B - Inverted traps are to be field-supplied and installed (typical). When installing traps, pro-

vide clearance for swing end of access door. Traps are to extend above base of coil by a

minimum of 7-1/2" (190 mm).

Liquid line

Electric

service

supplied by

others

Hot gas line

* B

LEE-TEMP CONDENSER