Intelligent pre-starts and pre-stops, 11 separate setpoints, 12 ahu zone control – Emerson E2 User Manual

Page 166: 13 hardware overview

11-24

•

E2 RX/BX/CX I&O Manual

comfortably within the range of the new setpoint.

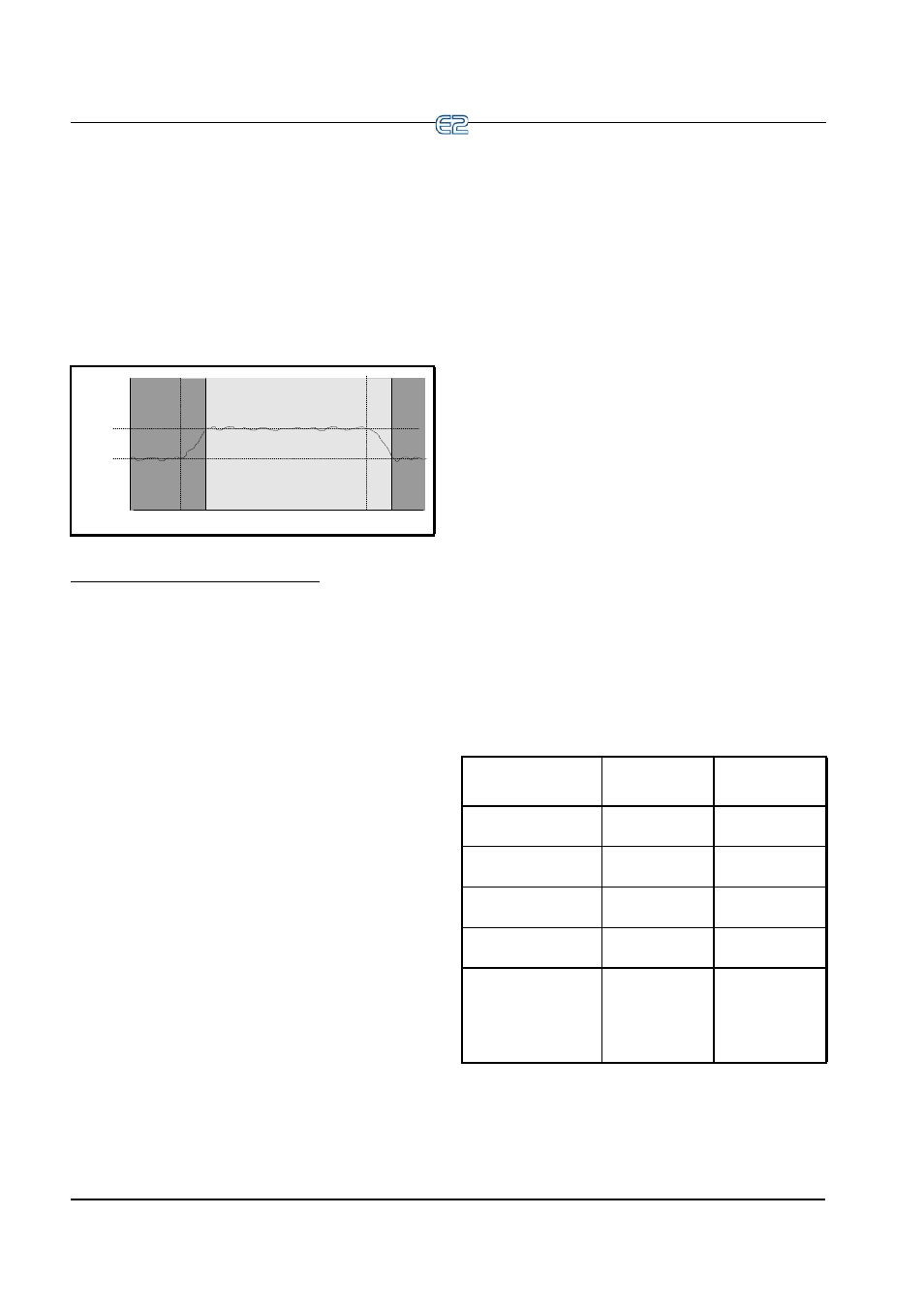

Figure 11-15 shows an example of how pre-starts and

pre-stops work in a heating application. From unoccupied

mode, the pre-start period ramps the temperature up

slowly so that when the scheduled change from unoccu-

pied to occupied mode occurs, the temperature will

already be at or near the occupied heating setpoint. During

the pre-stop, which occurs before AHU Control goes from

occupied to unoccupied mode, heating is suspended and

the temperature is allowed to “coast” down to the unoccu-

pied setpoint.

Intelligent Pre-Starts and Pre-Stops

OSS is designed to handle pre-starts and pre-stops in

the most energy-efficient manner possible. Every time a

pre-start or pre-stop occurs, OSS measures the amount of

time it takes to bring the temperature from the previous

setpoint to within the “comfort zone” of the new setpoint

(a user-defined range of values above and below the set-

point within which the temperature is considered accept-

able). This duration is used to determine the average rate

of temperature change, called the K factor.

The K factor is stored in the memory along with the

average value of the outdoor air temperature during the

pre-start or pre-stop. Over time, collected K factor data

will be sorted and combined into a table. As a result, by

constantly observing and recording the results of previous

pre-starts and pre-stops, OSS will be able to intelligently

guess how much time a pre-start or pre-stop mode should

last based on the outside temperature.

AHU Control keeps track of three different kinds of K

factors:

• Heat K factor - used to guess pre-start dura-

tions for AHUs operating in heating mode.

• Cool K factor - used to guess pre-start dura-

tions for AHUs operating in cooling mode.

• Coast K factor - a measurement of the

change in temperature when no heating or

cooling is active. This is used to determine

pre-stop durations for both heating and cool-

ing AHUs.

11.6.11 Separate Setpoints

The Separate Setpoints strategy for AHU allows a Cut

In/Cut Out setpoint to be set up for each heat and cool

stage instead of just one cool and one heat setpoint set up

for each stage (Normal strategy). Dehumidification con-

trol can be performed while controlling with separate set-

points.

11.6.12 AHU Zone Control

Unlike MultiFlex RTU rooftop controller applications,

AHU applications are not required to be grouped into

Zone applications (AHUs are usually large enough to be

“zones” in and of themselves).

However, if desired, you may associate an AHU Con-

trol application with a Zone application. The AHU will

then use the Zone’s Temperature Control setpoints, occu-

pancy state, summer/winter state, and economization and

dehumidification enable signals. More information on

Zone control is available in Section 11.7, Zone Control.

11.6.13 Hardware Overview

To set up an AHU for control by an E2, numerous tem-

perature and humidity sensors for several different appli-

cations must be connected to the I/O Network, as well as

fan and cool proof checking devices, economization

checking devices, curtailment devices, and all of the heat-

ing, cooling, and dehumidification outputs.

Listed below are wiring instructions for some of the

inputs and outputs that are part of a typical AHU setup.

Figure 11-15

- Diagram of Pre-Start and Pre-Stop Operation

OCCUPIED

SET POINT

UNOCCUPIED

SET POINT

UNOC

C

U

PIED

UNOC

C

U

PIED

PRE-ST

ART

OCC

U

PIED

PRE-ST

OP

(COAST)

26512036

Inputs

Sensor Type

Wiring

Instructions

Space Temperature

Temperature

Space Humidity

Humidity

Supply Air Temp

Temperature

Return Air Temp

Temperature

Outdoor Air Temp

Temperature

Set up as Out-

door Air Provider

in Global Data

(see

).

Table 11-10

- Suction Group Inputs