2 condenser control, 1 air cooled condensers, 1 air cooled strategy – Emerson E2 User Manual

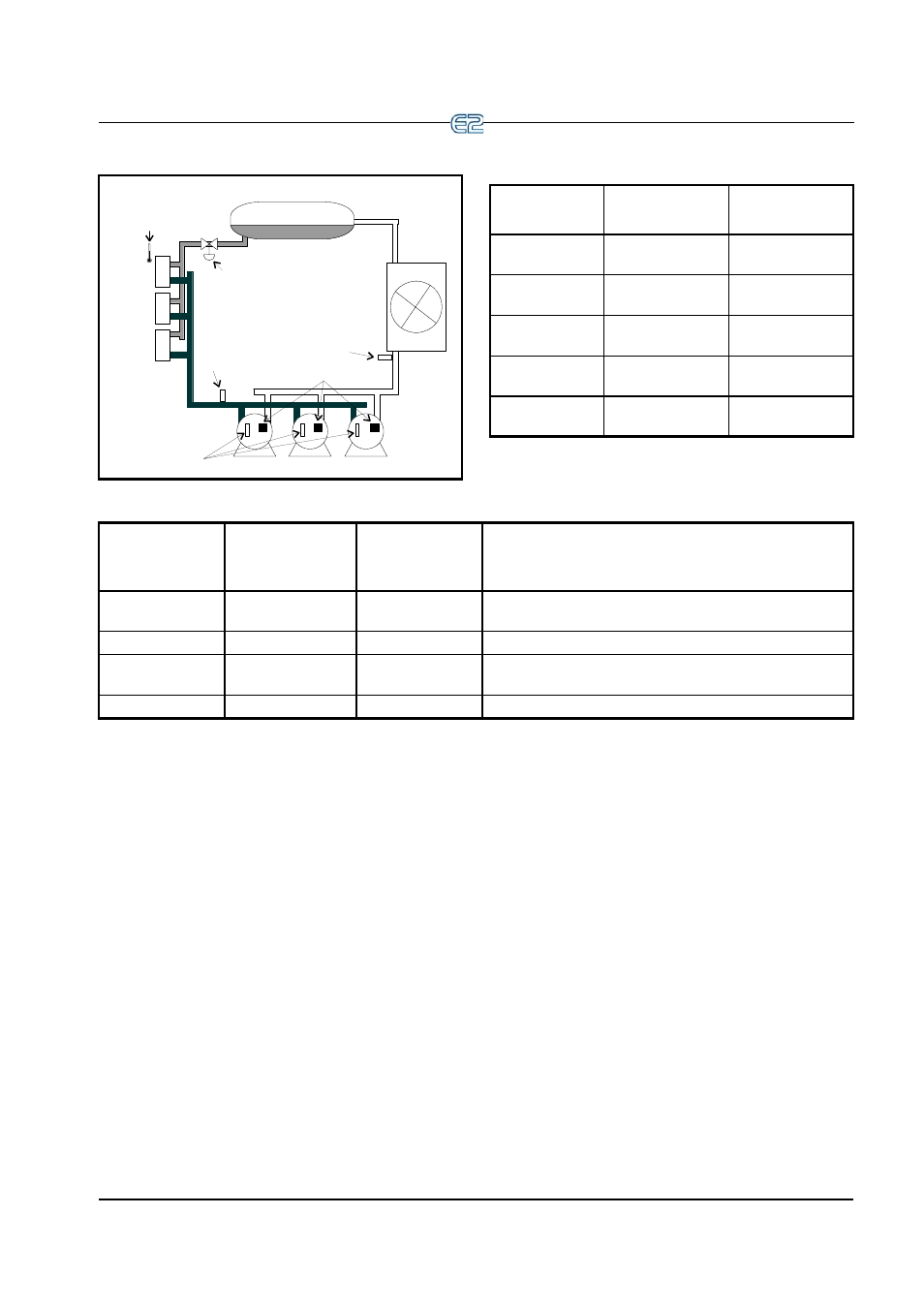

Page 145: 2 temperature differential strategy, Ondenser, Ontrol, 1 air cooled condensers -3, Figure 11-1, In table 11-1 and table 11-2, 2 temperature differential strat- egy

Condenser Control

Software Overview

•

11

-

3

11.2 Condenser Control

An E2 RX is capable of controlling air-cooled or evap-

orative condensers. The E2 RX-300 may control a single

condenser, while the RX-400 may control up to two con-

densers.

11.2.1 Air Cooled Condensers

An air-cooled condenser consists of one or more fans

that blow air across a manifold of tubing to cool heated

refrigerant and condense it into a liquid. The E2 controls

condensers by activating or deactivating fans in order to

maintain discharge pressure or temperature at or below a

chosen setpoint.

A Condenser Control application may use either of two

strategies to operate air cooled condensers: an air-cooled

strategy, or a temperature differential (T-D) strategy.

11.2.1.1 Air Cooled Strategy

The air cooled strategy uses a simple PID control loop

that compares a single Control In input to a PID setpoint.

The resulting percentage is used to activate the condenser

fan(s) necessary to bring the input value down below the

setpoint.

Control inputs for air cooled strategies most commonly

come from a pressure transducer mounted on either the

discharge line, the condenser inlet, or the condenser outlet.

However, temperature sensor values will also be accepted.

11.2.1.2 Temperature Differential Strat-

egy

The temperature differential strategy attempts to keep

a minimum amount of difference between the temperature

of the refrigerant and the ambient outside temperature.

This strategy begins by determining the temperature of

the refrigerant coming into the condenser. This can be sup-

plied by either a temperature sensor or pressure transducer

located near the condenser inlet; if it’s a pressure trans-

ducer, its value will automatically be converted to a tem-

perature value based upon the type of refrigerant.

Figure 11-1

- Diagram of a Suction Group

SUCTION

PRESSURE

CO

NDEN

S

E

R

DISCHARGE

PRESSURE

LIQUID RECEIVER

CASE CIRC

UIT

OIL

PRESSURE

CIRCUIT

CASE TEMP

(FOR FLOATING)

LIQUID LINE

SOLENOID

26507005

D

D

D

OIL RESET SWITCHES

Input

Sensor Type

Wiring

Instructions

Suction Pressure

100 lb. Eclipse

transducer

Discharge Pres-

sure

500 lb. Eclipse

transducer

Oil Pressure

200 lb. Eclipse

transducer

Case Circuit

Temperature

Temperature

Oil Reset

Switches

Digital

Table 11-1

- Suction Group Inputs

Output Device

Wire Output

Board Contacts

to:

Set Failsafe Dip

Switch to:

Notes

Compressor

N.C.

N.C. (up)

If you want a compressor to be OFF during network/power loss,

use N.O. failsafes instead.

Unloader

N.C.

N.O. (down)

These fail-safe settings are specifically for unloaders.

Liquid Line Sole-

noid (LLS)

N.C.

N.C. (up)

Keeps solenoid energized during network/power loss.

Electric Defrost

N.O.

N.O. (down)

Keeps contacts de-energized during network/power loss.

Table 11-2

- Suction Group Outputs