Sys tem op er a tion mon i tor 5, In di cating lights 5, Fig ure 2. sys tem op er a tion mon i tor 5 – Deltech Fitness PYRAMID 8000 User Manual

Page 11: System operation monitor, Indicating lights, Figure 2. system operation monitor

SYSTEM ALARM — The red SYSTEM ALARM

indicator signals air system or dryer operating condi-

tions that may affect dew point performance or cause

damage to the dryer.

Temperature SCAN/SEEK Push Button

The SCAN/SEEK push button on the System Opera-

tion Monitor provides a readout on the alphanumeric

display of the following temperatures:

•

inlet air

•

refrigerant suction

•

refrigerant discharge

•

ambient air

The display can be programmed to automatically scan

each temperature for five seconds in sequence or to

continuously display any selected reading. The corre-

sponding light on the system schematic will illuminate

when the temperature is displayed.

To scan the temperatures (normal operation): press

and hold the SCAN/SEEK button for three seconds.

Each temperature will then be displayed for five sec-

onds in the following sequence: inlet air, refrigerant

suction, refrigerant discharge and ambient air. To stop

the scan mode, press the TIME ADJUST button once.

To display any selected temperature (seek;

test/check mode): press the SCAN/SEEK button once.

The display will read the same temperature until the

button is pressed again. While in this mode, the alarm

set points and service due light are bypassed.

Critical Air and Refrigerant Temperatures

Table V provides the normal range for each displayed

temperature when the dryers are operated in accor-

dance with specified conditions. If a temperature

reaches the warning set point indicated in the table,

the corresponding light on the system schematic will

flash during the five second display. If the temperature

reaches the alarm set point indicated in the table, the

System Alarm indicator will light. Refer to the Field

Service Guide in this manual if any temperature read-

out falls outside the normal range.

Inlet Air Temperature — If the inlet air temperature

falls outside the normal range, the dryer may fail to

achieve the required dew point. Check the compressor

aftercooler and adjust aftercooler operation to ensure

specified inlet air temperature to the dryer.

Refrigerant Suction Temperature — If the dryer has

been operating for more than 20 minutes and the re-

frigerant suction light flashes, there may be a malfunc-

tion in the refrigeration system. Turn the dryer off and

have a refrigeration mechanic identify and correct the

malfunction. If the dryer is under warranty, call your

local distributor for authorization before servicing.

Pyramid 8000

®

Series Purifiers (Bulletin 289)

7

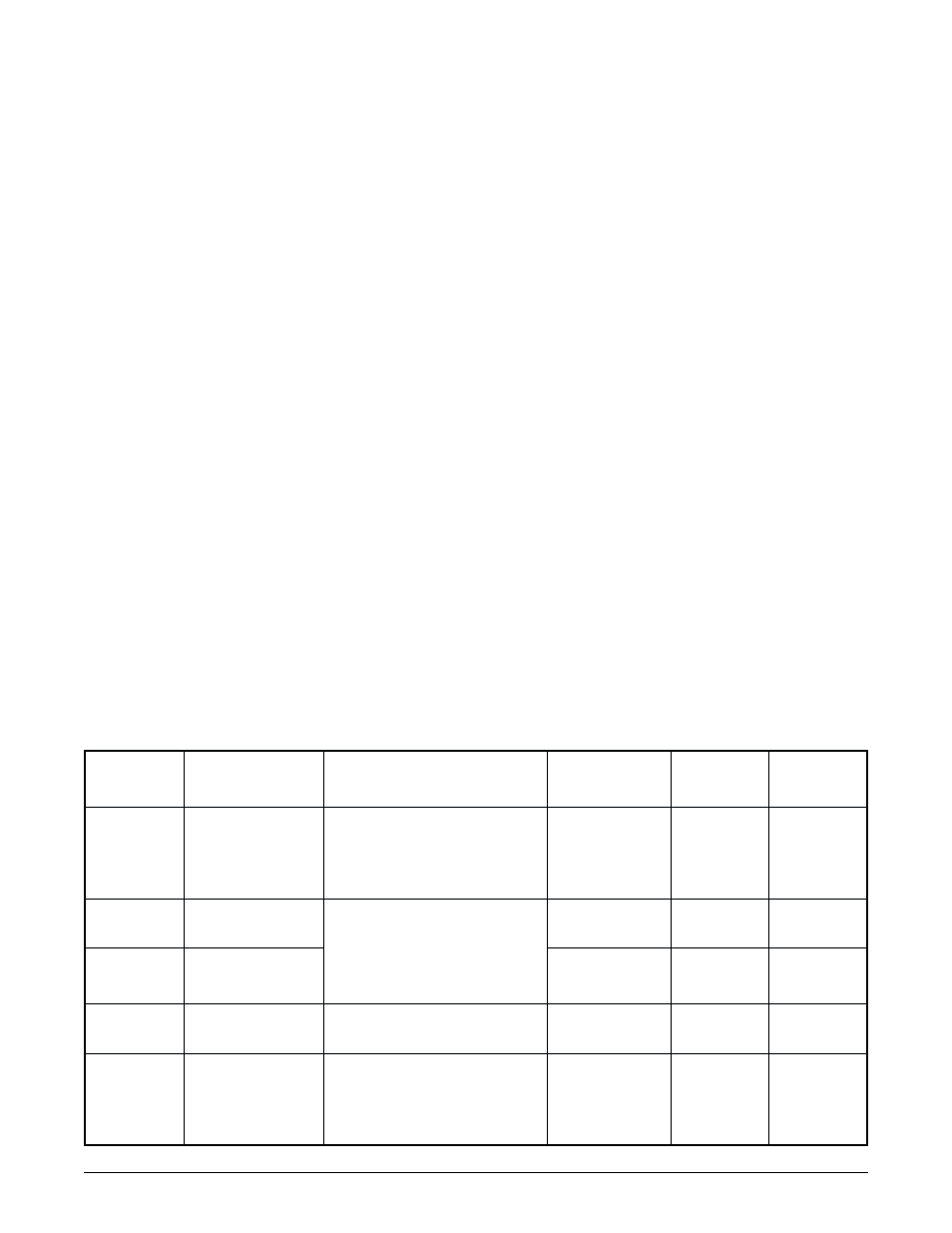

Table V

Air and Refrigerant Temperatures

DIGITAL

DISPLAY

THERMOCOUPLE

LOCATION

COMMENTS

NORMAL

TEMPERATURE

RANGE

WARNING

SET

POINT

ALARM SET

POINT

Inlet Air

Inlet air piping

Inlet air temperature varies with

changes in aftercooler cooling

medium temperature and air

compressor unloading. Inlet tem-

peratures higher than 100°F re-

duce drying capacity.

40°F – 120°F

100°F

120°F

Refrigerant

Suction

Refrigerant line up-

stream of compres-

sor

These refrigerant temperatures

vary with the refrigeration load

and are controlled by refrigera-

tion valve settings. These read-

ings are used primarily by service

personnel to analyze refrigeration

system performance.

32°F – 55°F

N.A.

25°F

Refrigerant

Discharge

Refrigerant line

downstream of

compressor

160°F – 240°F

N.A.

N.A.

Ambient Air

Outside the con-

denser

Ambient air temperatures higher

than 100°F will reduce drying ca-

pacity.

35°F – 120°F

> 100°F/

< 35°F

> 120°F/

< 35°F

Intermediate

Air

Outside surface of

chiller discharge

piping

Intermediate air temperature var-

ies with inlet air pressure, ambi-

ent temperature and airflow. This

reading is used primarily by serv-

ice personnel to analyze refrig-

eration system performance.

Variable; see

Table VI

N.A.

N.A.