Starting and stopping the tool, Locking switch in the “off” position, Spindle speeds – Delta 46-715 User Manual

Page 9: Aligning headstock center to tailstock center

9

STARTING AND STOPPING THE

TOOL

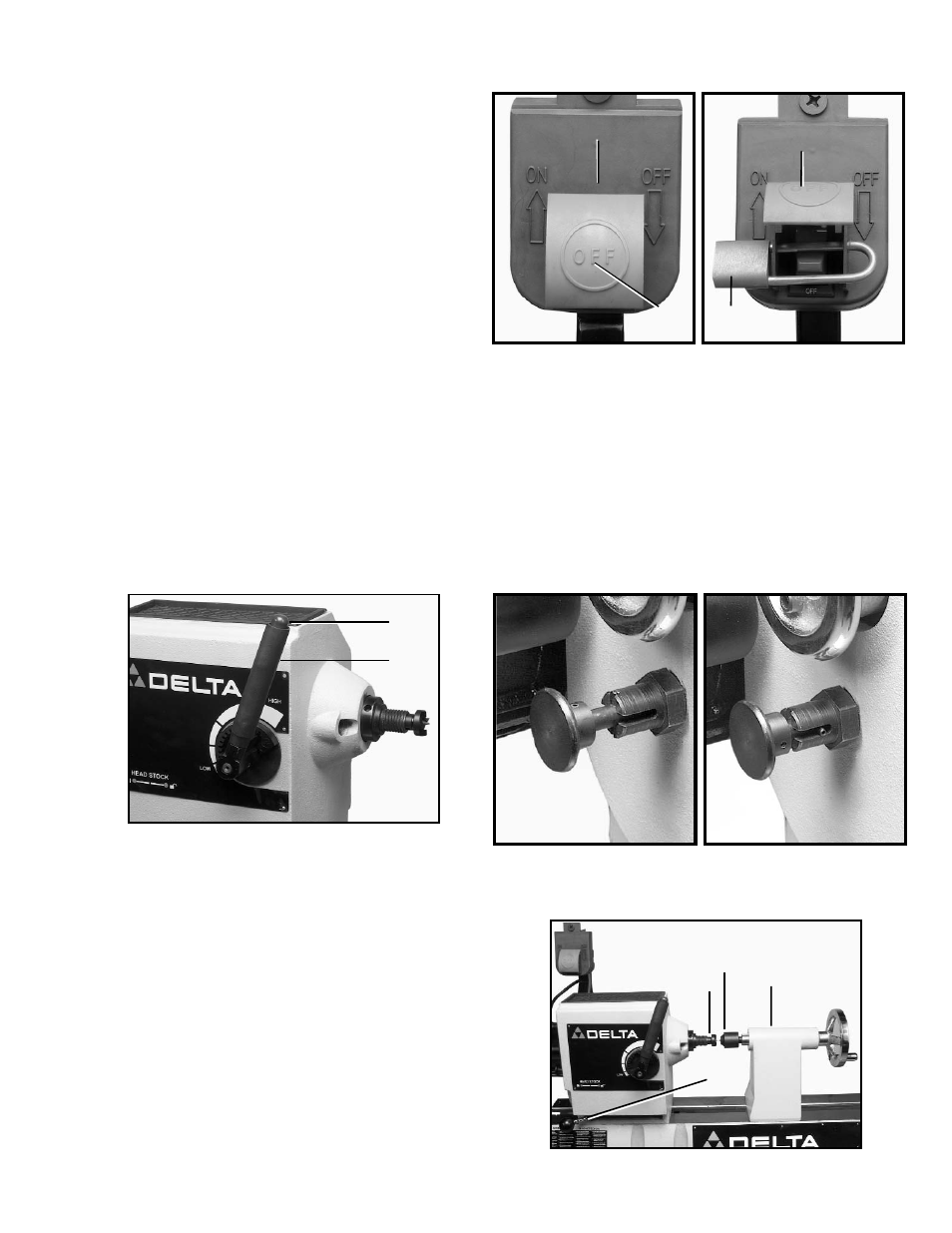

The switch (A) Fig. 21 provides electrical power to the

tool. To start the tool, lift the safety cover (B) and lift the

switch to the “ON” position. To stop the tool, push the

safety cover (B) down.

NOTE: IN CASE OF EMERGENCY,

IMMEDIATELY PUSH THE SAFETY COVER (B) DOWN TO

SHUT OFF POWER.

LOCKING SWITCH IN THE

“OFF” POSITION

IMPORTANT: When the tool is not in use, the switch

should be locked in the “OFF” position (A) Fig. 22 to

prevent unauthorized use, using a padlock (B) Fig.

22, with a 3/16" diameter shackle inserted through

the holes in the switch plate.

A

A

B

Fig. 21

Fig. 22

SPINDLE SPEEDS

IMPORTANT:

UNLOCK THE SPINDLE LOCK BEFORE OPERATING THE TOOL. THE UNLOCKED POSITION IS SHOWN

IN FIG. 24A WHILE THE LOCKED POSITION IS SHOWN IN FIG. 24B.

IMPORTANT: CHANGE SPEEDS ONLY WHEN TOOL IS RUNNING.

This tool provides variable rate spindle speeds from 450 to 2600 RPM. To change speeds, depress the release (A) Fig.

23 and rotate the lever (B). Turning the lever clockwise increases the speed while turning it counterclockwise decreas-

es the speed.

ALIGNING HEADSTOCK

CENTER TO

TAILSTOCK CENTER

The tailstock will move slightly when it is tightened. To

ensure that the tailstock center will always be in line with

the headstock center:

1.

Install the pointed centers (A) and (B) Fig. 25 into the

spindles.

2.

Loosen locking lever (back side of tailstock), and

slide the tailstock (D) to the left until the tailstock center

(B) is almost contacting the headstock center (A).

Tighten the locking lever. Check to see if the tailstock

center point (B) is in line with the headstock center point

(A).

3.

To adjust, loosen the headstock locking shaft (C)

Fig. 25, and align the headstock center point to the tail-

stock center point. Tighten the locking shaft (C) Fig. 25.

Fig. 24A

Fig. 24B

Fig. 23

Fig. 25

B

A

B

A

B

C

D