Faceplate turning, Mounting work to faceplate, Inboard/outboard turning – Delta 46-715 User Manual

Page 17

17

FACEPLATE TURNING

Mount turnings that cannot be worked between centers on a faceplate. The greater part of this

type of turning is done with the faceplate mounting, although there are a number of jobs which

require special chucks. All cutting in faceplate work is done by scraping. Any attempt to use a

cutting technique on the edge grain of large work will result in a hogging, gouging cut which may

jerk the chisel out of the hands of the operator. Use a band saw on all work to roughly cut the turn-

ing area slightly oversized to eliminate heavy roughing cuts in turning.

MOUNTING WORK

TO FACEPLATE

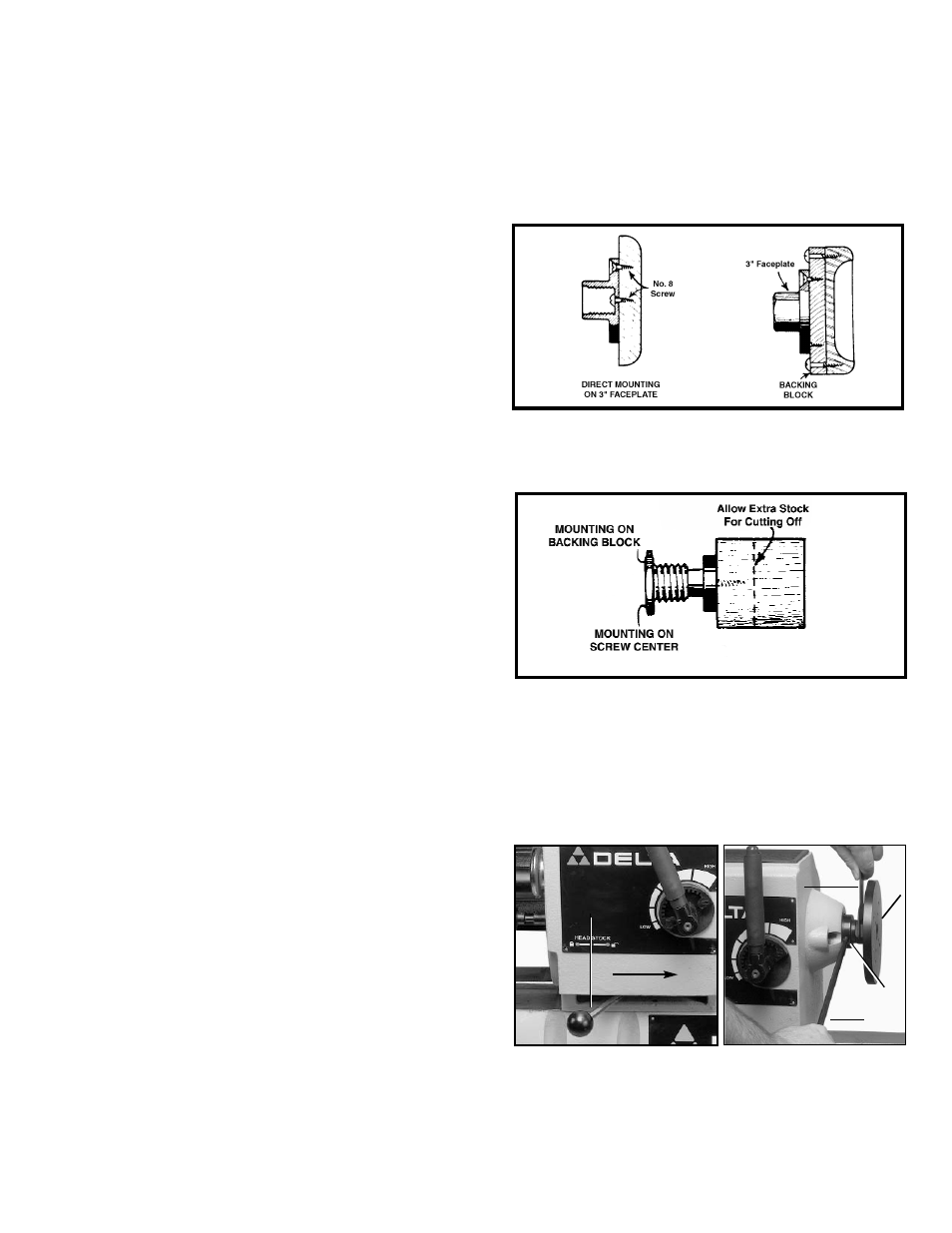

Fig. 63 shows direct mounting to the 3" faceplate along

with attaching to the backing block. Because of the ease

of setting up, use this mounting whenever the work per-

mits. Hold larger pieces in the same way by using the 6"

faceplate. When normal screw-fastenings interfere,

mount the work on a backing block (Fig. 63). When

screws are not permissible at all, glue the work to the

backing block by fitting a sheet of paper at the joint to

allow later separation without damaging the wood.

Some work can be screwed or nailed from the face side

into backing block. Mount work less than 3" in diameter

on the single screw center (Fig. 64).

Fig. 63

Fig. 64

INBOARD/OUTBOARD TURNING

For workpieces that require additional space for turning,

or for the turning of bowls, etc., outboard turning is the

answer. To make outboard turnings:

1.

Remove the tool rest base and the tailstock from

the lathe bed.

2.

The headstock can turn to any angle. Move the

handle (A) Fig.65 and turn the headstock to the angle

best suited for the work. Lock the headstock in place by

moving the handle back to the left.

5.

If the faceplate is already on the headstock, remove

it by inserting the knocko

ut bar (A) Fig. 66 in the side hole

of the spindle (B) Fig. 66 to hold the spindle in place. Use

the supplied wrench (C) Fig. 66 to loosen the faceplate.

Remove the faceplate (D) by turning it counterclockwise

with your hand.

Fig. 65

A

Fig. 66

A

B

C

D