Delta 46-715 User Manual

Page 18

18

6.

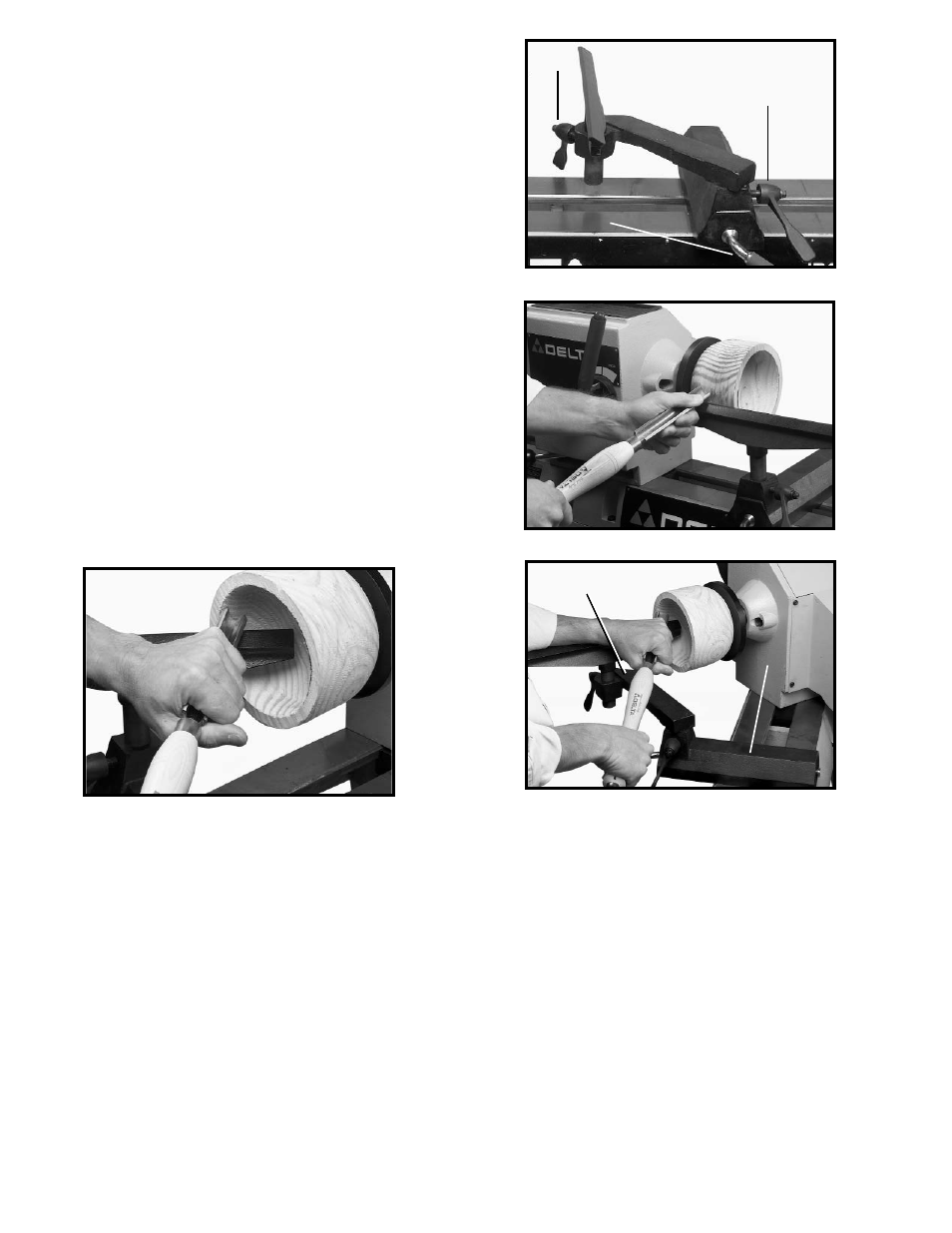

The tool rest with the auxiliary extension can be

placed in several different angles and positions. Select

the one best suited for your work. Fig. 67 shows the

position normally used for bowls and other outboard

turnings. To move the tool rest on the bed, loosen the

handle (A) Fig. 67 and slide the tool rest to the desired

position, and then tighten the handle. To change the

angle of the tool rest, loosen the handle (B) Fig. 67,

move the auxiliary extension to the desired position,

then retighten. To raise the height of the tool rest, loosen

the handle (C), raise the tool rest to the desired height,

then retighten.

7.

Fig. 68 illustrates a typical inboard faceplate turning

set-up. Inboard faceplate turning is used mostly when

the workpiece (A) will rotate freely over the lathe bed.

The workpiece (A) is mounted to a faceplate and the

faceplate is threaded onto the spindle. Note that the

standard equipment tool rest (B) can be adjusted to turn

the outside diameter of the workpiece. Fig. 69 illustrates

the rough cutting of the inside of a bowl.

8.

Outboard turning is illustrated in Fig. 70. Note that

the headstock (A) is turned 45 degrees and the tool rest

auxiliary extension (B) is attached. Outboard turning

generally is used for larger workpieces, but smaller work

can be accomplished using this technique.

Fig. 67

A

B

C

Fig. 68

Fig. 69

Fig. 70

A

B