Woodhaven 5432: HD Panel Master User Manual

Page 4

USING THE HD PANEL MASTER

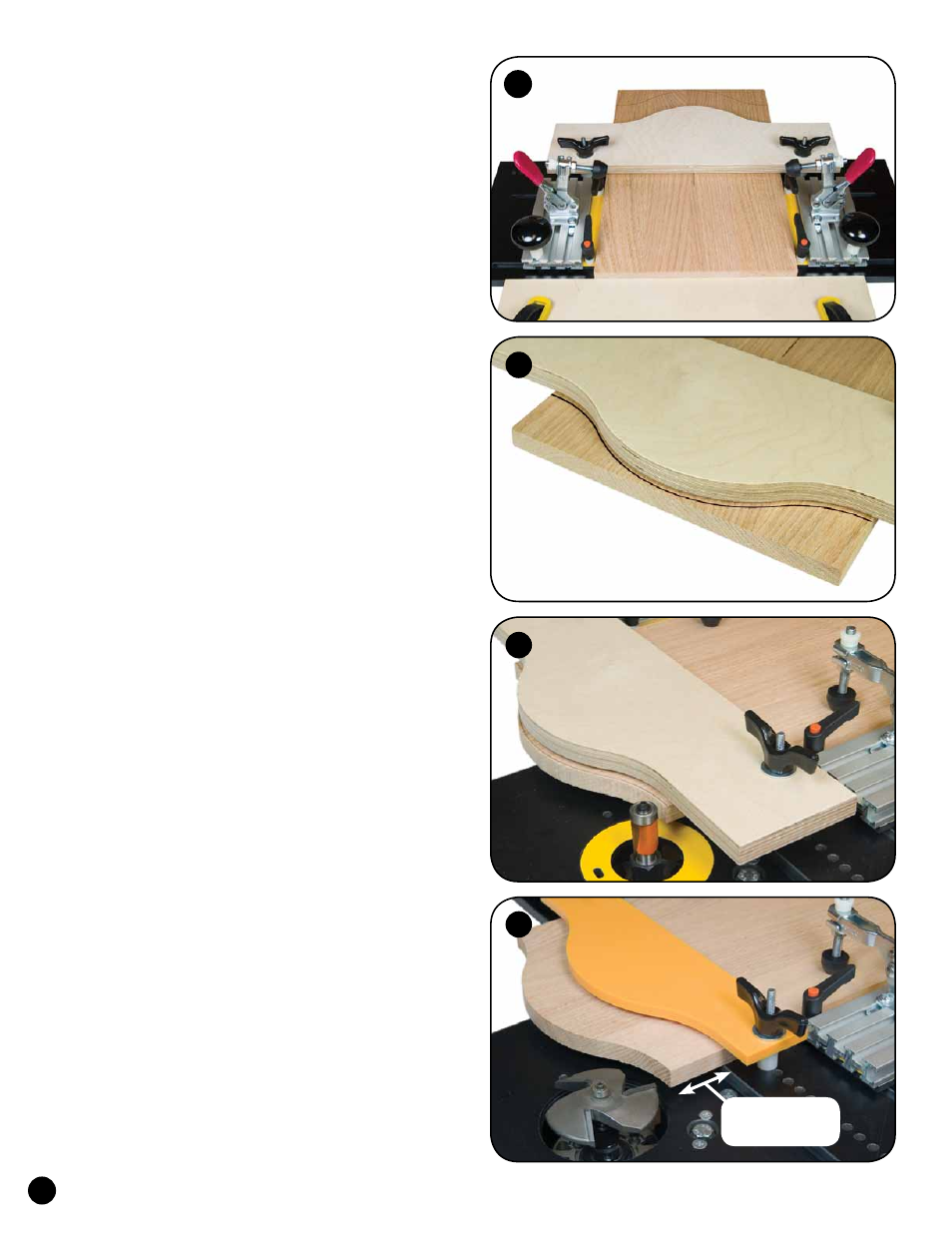

Mark a centerline on your panel and cut one end square.

Insert the panel between the template and the base of the HD

Panel Master. Lay the Panel Master on a bench, clamp a 3/4"

thick piece of scrap to your bench and butt the back edge of the

HD Panel Master and the square end of the panel up against

it. This serves to square the fences/panel on the base. Slide

the fences up against each side of the panel, center the panel

to the template and tighten the fence knobs. See fig. 9.

Place the panel in the Panel Master at the desired

finished length. Trace the outline of the template

on the panel, remove the panel and cut it to shape,

staying 1/8" or less from the line. See fig. 10

FLUSH TRIM PANEL

Clamp the panel in the HD Panel Master, hold the

handles and flush trim the panel to shape using a flush

trim cutter on your router or shaper. See fig. 11.

Next operation is cutting the raised panel, and you can use

the HD Panel Master for that too. Install the cutter and adjust

the height, taking into account the 1/2" thickness of the base.

You may want to set up an extra machine so you can switch

between flush trimming and panel raising operations quickly.

FOR ROUTER PANEL RAISING

The door template (you can use either Standard or

HD Door Templates) can be removed (not mandatory) as the

bearing will follow the panel, not the template. It's important

that the panel project past the edge of the base approximately

1-3/4" so there is no risk of the router bit striking the base.

This is the automatic position of the panel if using the larger

HD Door Templates, but not the smaller Standard Door

Templates. Make sure you have at least 3/4" of the bit

shank in the router. If extra bit height is needed, you may

need to use a router lift or collet extension. See fig. 12.

FOR SHAPER PANEL RAISING

DO NOT use Standard Door Templates with a shaper!!

If possible (depends on raised panel cutter & bearing set up),

keep the HD Door Template on the HD Panel Master for the

raised panel cut. The templates are extra long so the bearing

can make contact with the template before the cutter makes

contact with the panel, allowing the template to act as a starting

pin. Make sure the template is in line with the raised panel

cutter bearing. Clamp the panel in the HD Panel Master with

the toggle clamps, hold the the handles and cut the raised panel

using the raised panel cutter on your shaper. See cover image.

©Copyright WOODHAVEN INC. 12/21/06

(800) 344-6657 or WWW.WOODHAVEN.COM

11

10

3

9

12

Adjust fences so panel center lines

up with template center

Square cut end of panel

3/4" Scrap clamped to bench

Draw line for rough cut

HD Door Template

Standard Door

Template

Approximately

1-3/4"