Woodhaven 4556: Portable Box Joint Jig User Manual

Page 3

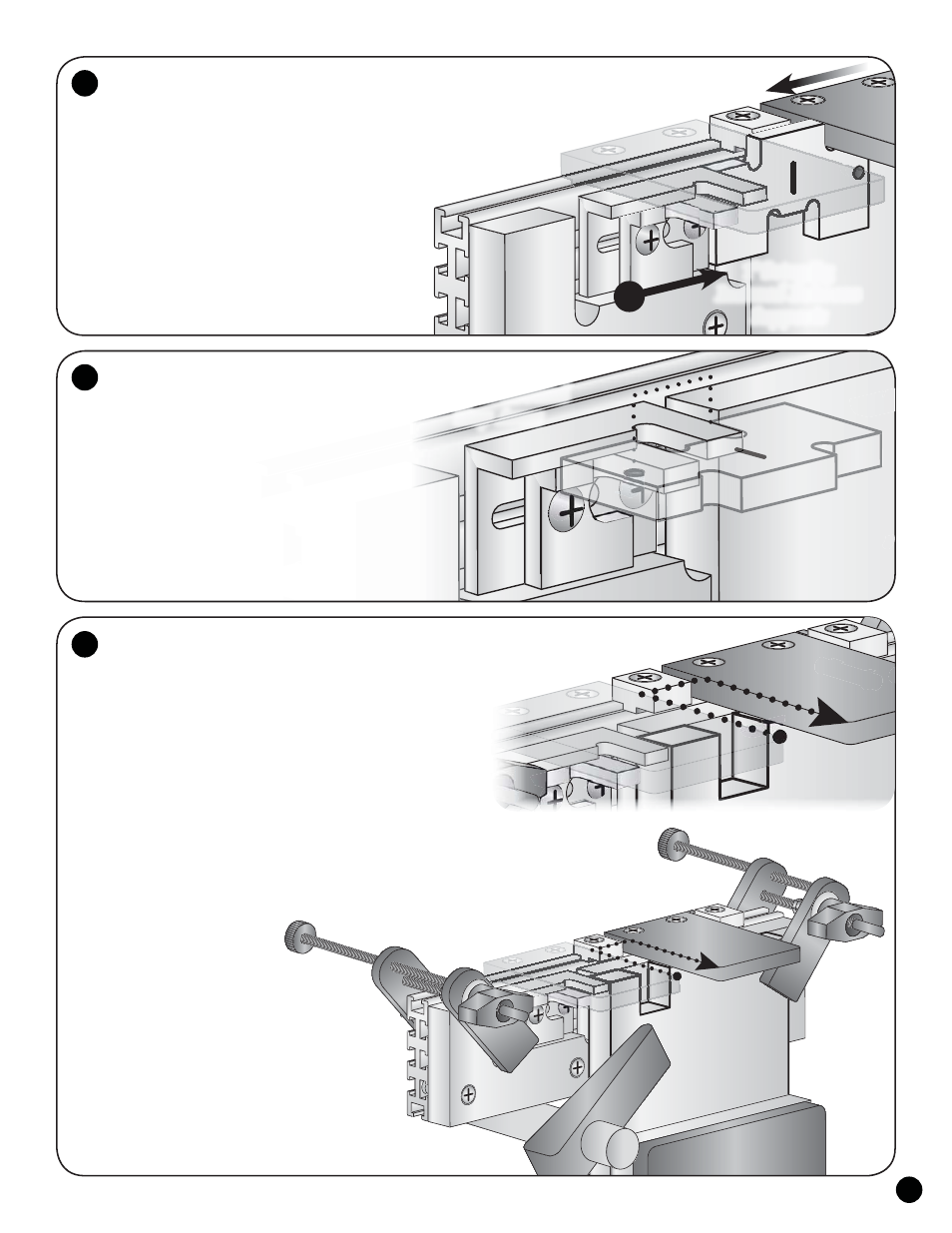

2

Adjust Aluminum

Stops for joint size:

Slide the right outside edge of the leg of the

Stationary Stop against the left outside edge of

the Setup Jig and tighten the Stationary Stop.

Rotate the Setup Jig 180º so the notch is against the

underside of the Router Supports and straddles both of the

legs of the Aluminum Stops. With the right inside edge of

the Setup Jig against the right outside edge of the leg of

the Stationary Stop, position the left edge of the leg of the

Adjustable Stop against the left inside edge of the Setup

Jig. Tighten the Adjustable Stop and remove the Setup Jig.

Test Cuts:

Use two wood scraps about 6" square. Clamp the bottom 2"

of one in a vise and rest the Left and Right Supports on the top

of the work, with the right side of the Stationary Aluminum Stop butted

against the left edge of the work. Adjust and tighten the right Clamp Pad

to hold the jig to the work. In addition, for the first and last few cuts of

every part, you'll need to use a small bar clamp to clamp the work to the

jig, since you can only use one of the two Clamp Pads for these cuts.

Set the cutting depth of the bit to the thickness of work

PLUS the thickness of the Left/Right Support PLUS the desired

amount of overhang. Any overhang can be removed later after

assembly by sanding or flush trimming. Make sure you allow for

this overhang when figuring the overall length of the work.

The Aluminum Stops protrude past the face of the Sub-Fence

and should always be to the left of the cutting path of the bit, when

viewed from the front. Before cutting, verify the bit will not contact

the Stops, Sub-Fence screws

or anything metallic.

Make the cut in a clockwise

fashion by running the bushing/

bit along the Left Router Support

until it bottoms out against the Router Stop(s),

move to the right, then come back out along

the Right Router Support. Wide or deep joints

require one of two cutting methods for best results:

A.) Cut at full depth, gradually roughing out most

of the center area first before making a light finish

cut along the Router Supports. B.) Make shallow

depths of cut until the full depth of cut is achieved.

Make sure the router is resting firmly on the

Left and Right Router Supports and that the bit is not

touching the work. Cut a single finger/notch in both test pieces.

6

7

Adjust Right Router

Support for joint size:

The Right Router Support is the ONLY Support you'll

make any adjustments to during use. The Left Router Support

will always remain stationary. Adjusting the Right Support

in relation to the Left Support determines the width of cut.

From the Inch Setup Jigs, select the size joint (1/2", 3/4",

1", 1-1/4" & 1-1/2") you wish to cut and remove it from the

chain. Loosen the Right Support. Loosen both Aluminum

Stops and slide them to the far left. Sandwich the "tall"

portion of the selected Setup Jig between the Supports then

tighten the Right Support. When using the 1/2" Setup Jig,

check to make sure the 3/4" guide bushing will fit between the

Supports and readjust the Right Router Support as necessary.

5

1" Setup Jig

Indexed Between

Supports

1" Setup Jig

Indexed Around

Stop Arms

Stationary

Support

Router

Travel Path

Vise

Bar

Clamp

First

Edge

Second

Edge

Workpiece

One