Woodhaven 6000: Horizontal Router Table User Manual

Page 4

To

MF

58

P

M

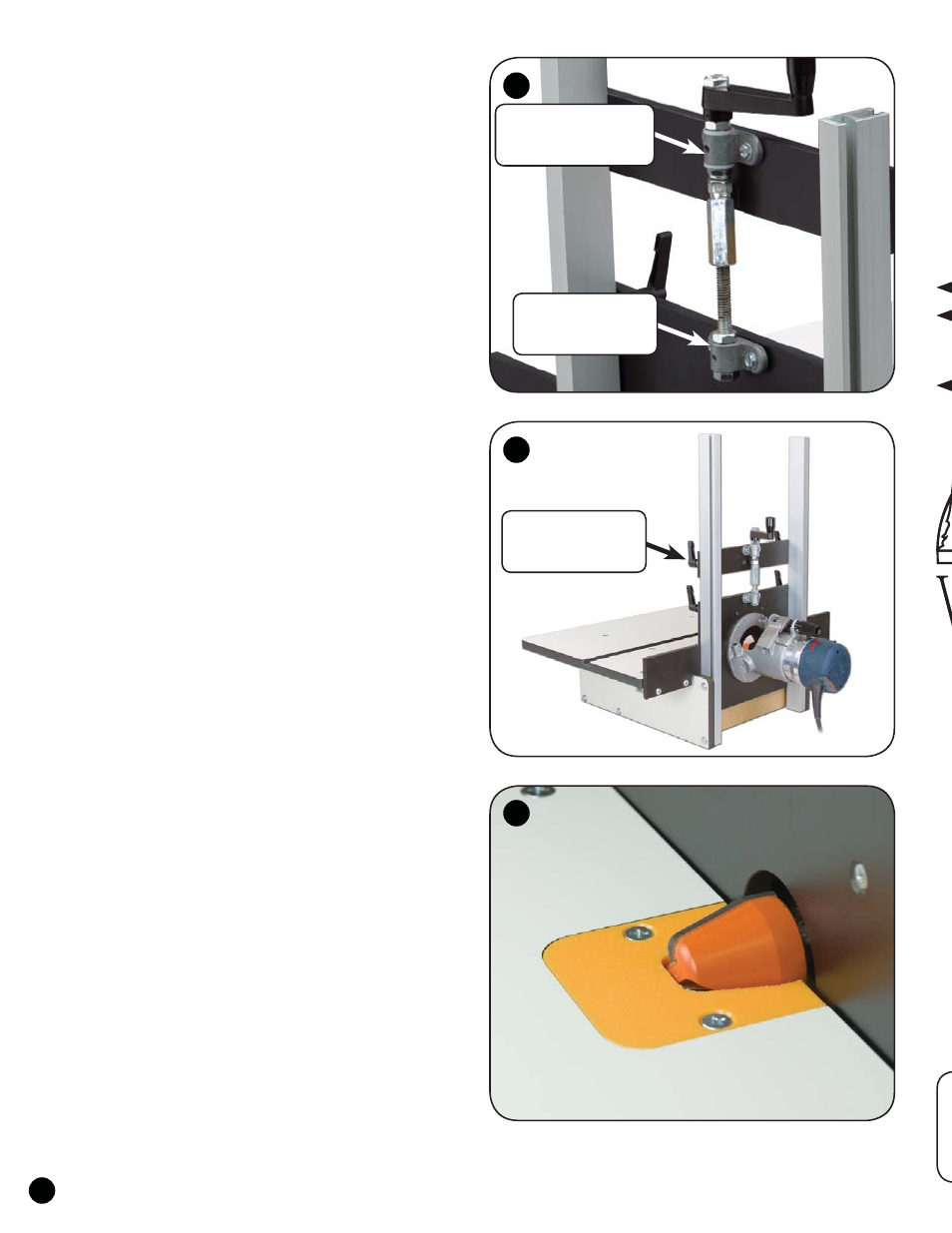

INSTALL CRANK HANDLE & ROUTER

Get the crank handle (6000C). There are two assemblies

to this part - one has a crank & nut, the other has a bolt

and both have a mounting bracket with two holes. Attach

the bolt assembly to the back top of the router plate with

two 1/2" screws (5770B) thru the two holes in its mounting

bracket, but leave them loose for now. See fig. 10 & 11.

Install the crank assembly on the back of the crank

support (6000B - the side with the machined ends)

using two 1/2" screws (5770B) thru the two holes in its

mounting bracket, but leave them loose for now. From

the front of the support, insert a washer (WS002) on each

stud of the ratchet handle (5859), insert the stud thru the

hole at each end and start an oval nut (5760B - smooth

side first) on the end of the studs. See fig. 10 &11.

Slide the support/oval nuts onto the 24" tracks until

the nut of the crank lines up with the bolt on the plate.

Turn the crank to screw the nut onto the bolt approximately

1", then tighten the ratchet handles on the crank support

and the four 1/2" screws (5770B). See fig 10 & 11.

ATTACH ROUTER & GUARD

Mount your router on the router plate. Insert the two

thumb screws (5503) thru the slots of the Guard (224) and

into the threaded holes in the router plate. See Cover.

MOUNT ZERO-CLEARANCE INSERT

Mount a zero-clearance insert (6000N) in the recessed

opening in the table using the two 3/4" screws (MF010). An

extra insert is provided and extras may be ordered. See fig. 12.

USING THE HORIZONTAL ROUTER TABLE

The crank provides 1-3/8" of fine bit height adjustment.

By loosening the two ratchet handles on the crank support,

you can move the entire router plate/crank support assembly

up or down for a great range of coarse adjustment.

Make sure the two handles on the router plate are

loosened and the two handles on the crank support are tight

before attempting to turn the crank. Make sure you tighten

the router plate handles after all height adjustments.

Clamp or bolt the horizontal table to a workbench before

using. The horizontal table can be used for mortising, edge

routing, vertical panel bits, cutting tenons, etc. For safety, we

recommend the bit be kept under the work/table during use.

For mortising, we recommend our optional 6010 or 6011

Mortising Table. For additional safety and routing consistency

we recommend using the 6000HD Hold-All Kit we include.

©Copyright WOODHAVEN INC. 12/14/10

(800) 344-6657 or WWW.WOODHAVEN.COM

3

10

11

12

Attach crank assembly

to 6000B Crank

Support w/1/2” screws.

Attach bolt assembly

to Router Plate

w/1/2” screws.

Attach 6000B Crank

Support to 24” tracks

w/ratchet handles.