Controls - aurora base control cont, Field selectable options via software, Safety features – WaterFurnace Envision2 User Manual

Page 29

29

ENVISION

2

COMPACT - 50 HZ INSTALLATION MANUAL

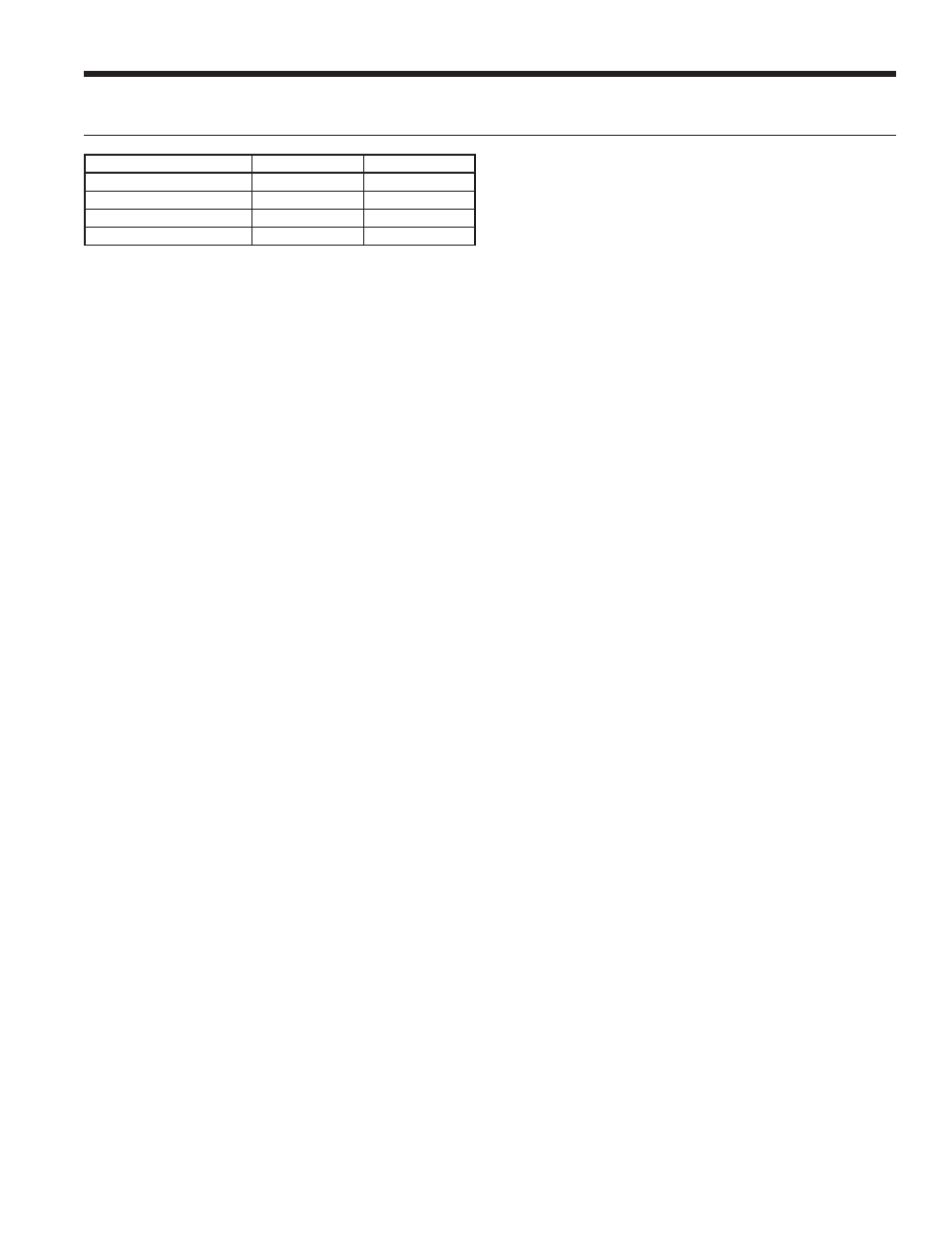

Access Relay Operation

SW2-4

SW2-5

Cycle with Blower

ON

ON

Cycle with Compressor

OFF

OFF

Water Valve Slow Opening

ON

OFF

(Reserved)

OFF

ON

Cycle with Blower - The accessory relay will cycle with

the blower output.

Cycle with Compressor - The accessory relay will cycle

with the compressor output.

Water Valve Slow Opening - The accessory relay will

cycle and delay both the blower and compressor output

for 90 seconds.

SW2-6 CC Operation – selection of single or dual capacity

compressor. On = Single Stage; Off = Dual Capacity

SW2-7 Lockout and Alarm Outputs (P2) – selection of a

continuous or pulsed output for both the LO and

ALM Outputs. On = Continuous; Off = Pulsed

SW2-8 Reheat Operation – On = Normal; Off = Reheat

Alarm Jumper Clip Selection

From the factory, ALM is connected to 24 VAC via JW2. By

cutting JW2, ALM becomes a dry contact connected to ALG.

Variable Speed ECM Blower Speeds

The blower speeds can be changed either by using the

variable speed ECM manual configurations mode method

or by using the Aurora AID Tool directly (see Instruction

Guide: Aurora Interface and Diagnostic (AID) Tool topic).

Field Selectable Options via Software

(Selectable via the Aurora AID Tool)

Variable Speed ECM Blower Speeds

A traditional variable speed ECM blower motor can be

driven directly using the onboard PWM output. Three

blower speeds are available, based upon the G (low), Y1

(med), and Y2/W (high) input signals to the board. The

blower speeds can be changed either by the variable speed

ECM manual configurations mode method (see Variable

Speed ECM Configuration Mode topic) or by using the

Aurora AID Tool directly. All three blower speeds can be set

to the same speed if desired.

Safety Features

The following safety features are provided to protect

the compressor, heat exchangers, wiring and other

components from damage caused by operation outside of

design conditions.

Fuse – a 3 amp automotive type plug-in fuse provides

protection against short circuit or overload conditions.

Anti-Short Cycle Protection – 4 minute anti-short cycle

protection for the compressor.

Random Start – 5 to 80 second random start upon power up.

Fault Retry – in the fault condition, the control will stage off

the outputs and then “try again” to satisfy the thermostat

Y input call. Once the thermostat input calls are satisfied,

the control will continue on as if no fault occurred. If 3

consecutive faults occur without satisfying the thermostat

Y input call, then the control will go to Lockout mode.

Lockout – when locked out, the blower will operate

continuously in low speed, and PSC blower motor output will

remain on. The Alarm output (ALM) and Lockout output (L)

will be turned on. The fault type identification display LED1

(Red) shall flash the fault code. To reset lockout conditions

with SW2-8 On, thermostat inputs “Y1”, “Y2”, and “W”

must be removed for at least three (3) seconds. To reset

lockout conditions with SW2-8 Off, thermostat inputs “Y1”,

“Y2”, “W”, and “DH” must be removed for at least three (3)

seconds. Lockout may also be reset by turning power off for

at least 5 seconds or by enabling the emergency shutdown

input for at least 3 seconds.

Lockout With Emergency Heat - if the control is locked

out in the heating mode, and a Y2 or W input is received, the

control will operate in the emergency heat mode while the

compressor is locked out. The first emergency heat output will

be energized ten (10) seconds after the W input is received,

and the blower will shift to high speed. If the control remains

locked out, and the W input is present, additional stage of

emergency heat will stage on after two (2) minutes. When the

W input is removed, all of the emergency heat outputs will

turn off, and the variable speed ECM blower will shift to low

speed and PSC blower motor output will remain on.

High Pressure – fault is recognized when the Normally

Closed High Pressure Switch, P4-9/10 opens, no matter

how momentarily. The High Pressure Switch is electrically in

series with the Compressor Contactor and serves as a hard-

wired limit switch if an overpressure condition should occur.

Low Pressure - fault is recognized when the Normally

Closed Low Pressure Switch, P4-7/8 is continuously open

for 30 seconds. Closure of the LPS any time during the 30

second recognition time restarts the 30 second continuous

open requirement. A continuously open LPS shall not be

recognized during the 2 minute startup bypass time.

Loss of Charge – fault is recognized when the Normally

Closed Low Pressure Switch, P4-7/8 is open prior to the

compressor starting.

Controls - Aurora Base Control cont.