Open loop ground water systems, Ground source loop system checkout – WaterFurnace Envision2 User Manual

Page 14

14

ENVISION

2

COMPACT - 50 HZ INSTALLATION MANUAL

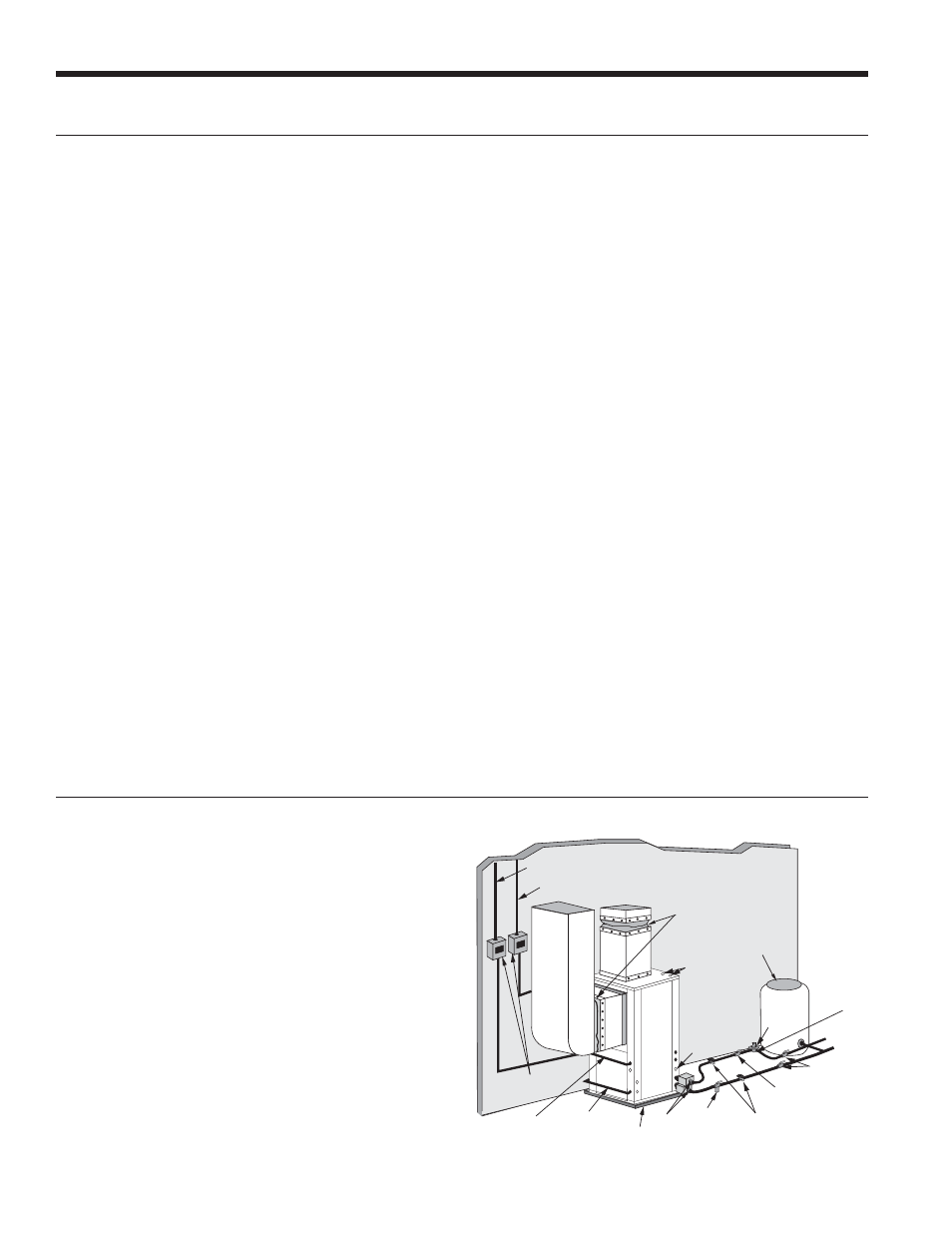

Typical open loop piping is shown below. Always maintain

water pressure in the heat exchanger by placing water

control valves at the outlet of the unit to prevent mineral

precipitation. Use a closed, bladder-type expansion tank

to minimize mineral formation due to air exposure. Insure

proper water flow through the unit by checking pressure

drop across the heat exchanger and comparing it to the

figures in unit capacity data tables in the specification

catalog. 0.09-0.13 L/s of flow per ton of cooling capacity is

recommended in open loop applications. Due to only minor

differences in flow rate from low to high, only one solenoid

valve should be used. The valve should be sized for full flow.

Discharge water from the unit is not contaminated in any

manner and can be disposed of in various ways, depending

on local codes, i.e. recharge well, storm sewer, drain field,

adjacent stream or pond, etc. Most local codes forbid the use

of sanitary sewer for disposal. Consult your local building and

zoning departments to assure compliance in your area.

Open System - Groundwater Application

Flexible

Duct Collar

Vibration

Absorbing Pad

P/T Plugs

Drain

Hot Water Generator

Connections

Low Voltage

to Thermostat

and Valve

Unit Supply

Aux. Heat Supply

Water Out

Water In

Shut Off Valves

Boiler Drains

For HX Flushing

Disconnects

(If Applicable)

Rubber Bladder

Expansion Tank

Solenoid

Valve

Shut Off Valves

(to isolate solenoid

valve while acid flushing)

Strainer

Flow Control

Valve

(on outlet of

Solenoid Valve)

Compressor

Line Voltage

Open Loop Ground Water Systems

System Cleaning and Flushing cont.

be opened for initial flush and blowdown, making sure

water fill valves are set at the same rate. Check the pressure

gauge at the pump suction and manually adjust the make-

up water valve to hold the same positive pressure both

before and after opening the drain valves. Flushing should

continue for at least two hours, or longer if required, until

drain water is clean and clear.

The supplemental heater and/or circulator pump, if used,

should be shut off. All drains and vents should be opened

to completely drain the system. Short-circuited supply and

return runouts should now be connected to the unit supply

and return connections.

Refill the system with clean water. Test the system water

for acidity and treat as required to leave the water slightly

alkaline (pH 7.5 to 8.5). The specified percentage of

antifreeze may also be added at this time. Use commercial

grade antifreeze designed for HVAC systems only.

Environol™ brand antifreeze is recommended.

Once the system has been filled with clean water and

antifreeze (if used), precautions should be taken to protect

the system from dirty water conditions. Dirty water will

result in system-wide degradation of performance, and

solids may clog valves, strainers, flow regulators, etc.

Additionally, the heat exchanger may become clogged

which reduces compressor service life and can cause

premature unit failure.

In boiler/tower application, set the loop control panel

set points to desired temperatures. Supply power to all

motors and start the circulating pumps. After full flow has

been established through all components including the

heat rejector (regardless of season), air vented and loop

temperatures stabilized, each of the units will be ready for

check, test and start up and for air and water balancing.

Ground Source Loop System Checkout

Once piping is completed between the unit pumping

system and ground loop, final purging and charging of

the loop is needed. A high pressure pump is needed to

achieve adequate flow velocity in the loop to purge air

and dirt particles from the loop itself. Antifreeze solution

is used in most areas to prevent freezing. Flush the

system adequately to remove as much air as possible;

then pressurize the loop to a static pressure of 276-345

kPa (summer) or 345-517 kPa (winter). This is normally

adequate for good system operation. Loop static pressure

may decrease soon after initial installation, due to pipe

expansion and loop temperature change. Running the

unit for at least 30 minutes after the system has been

completely purged of air will allow for the “break-in”

period. It may be necessary to adjust static loop pressure

(by adding water) after the unit has run for the first time.

Loop static pressure will also fluctuate with the seasons.

Pressures will be higher in the winter months than during

the cooling season. This fluctuation is normal and should be

considered when charging the system initially.

Ensure the pump provides adequate flow through the unit

by checking pressure drop across the heat exchanger.

Usually 0.14-0.19 L/s of flow per ton of cooling capacity is

recommended in earth loop applications.