SOR Vane Operated Flow Switch User Manual

Page 3

Form 588 (04.13) ©SOR Inc.

3/4

Process Connection

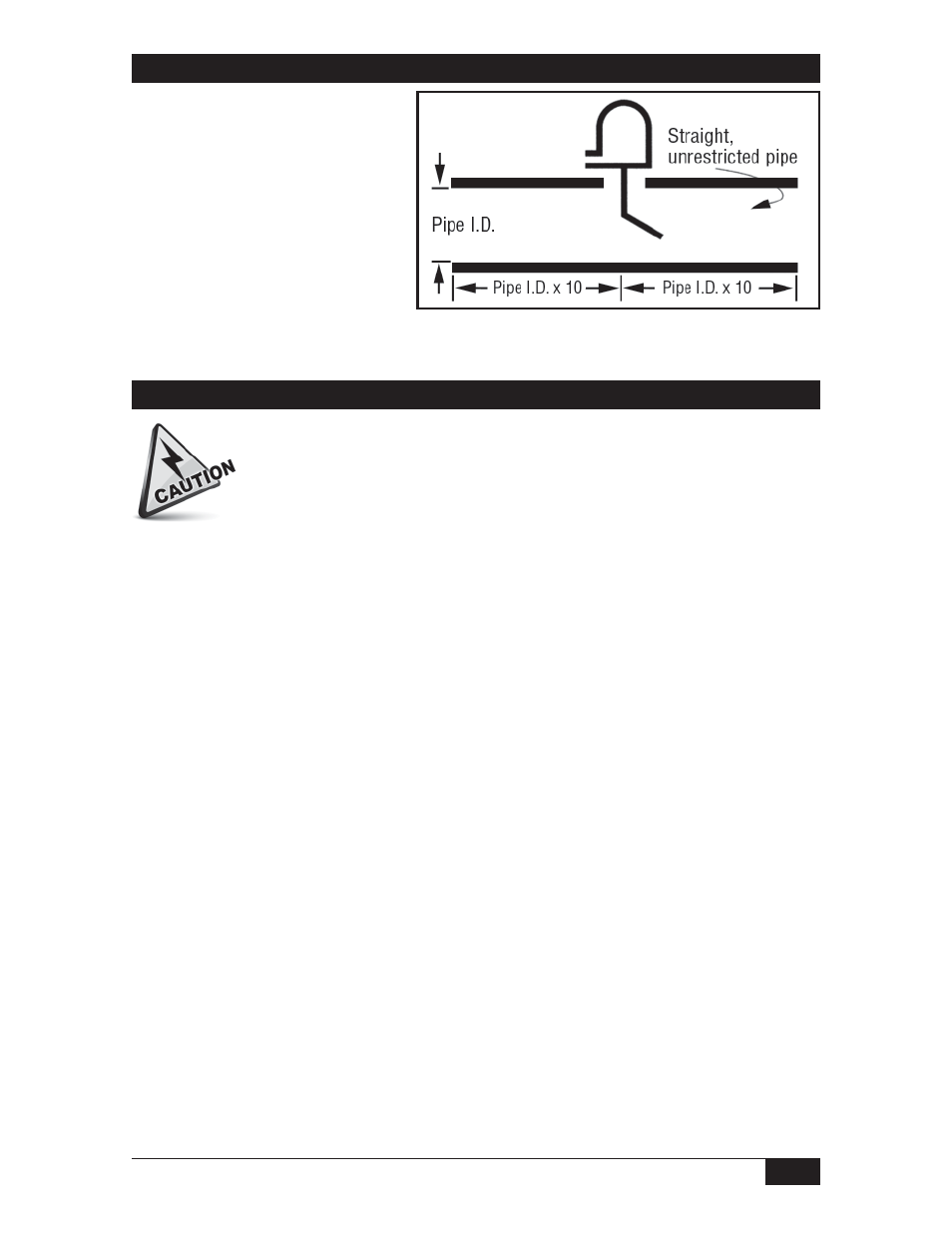

Integrally mounted controls should

be mounted with the vessel flange

or nozzle within 3° of the vertical or

horizontal centerline of the vessel,

as applicable.

Control should be mounted with

ten diameters (pipe ID x 10) length

straight, unrestricted pipe on

both sides.

Insulation of the control is not recommended.

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

Switch housing conduit connections can be rotated 360° by loosening the set screw

located under the housing base. Do not attempt to rotate the housing without loosening set

screw. Retighten the set screw after adjusting the housing.

Care must be taken in positioning the incoming wiring to ensure clearance between the

wiring and switch housing. Switch wiring should be brought through the conduit

connection, under the baffle plate, wrapped around the sealing tube and brought up to

the proper terminal. All excess wire should be cut off prior to stripping the wire to avoid

interference with the action of the switch mechanism or housing cover.

All housings must be properly “sealed” at the conduit connection to maintain the

NEMA classification.

Check housing-to-base fit to ensure the gaskets are sealing properly.

Electrical Connection

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.