Process connection – SOR Explosion Proof Pressure Switch UL/CSA/ATEX User Manual

Page 2

2/8

Form 316 (01.13) ©SOR Inc.

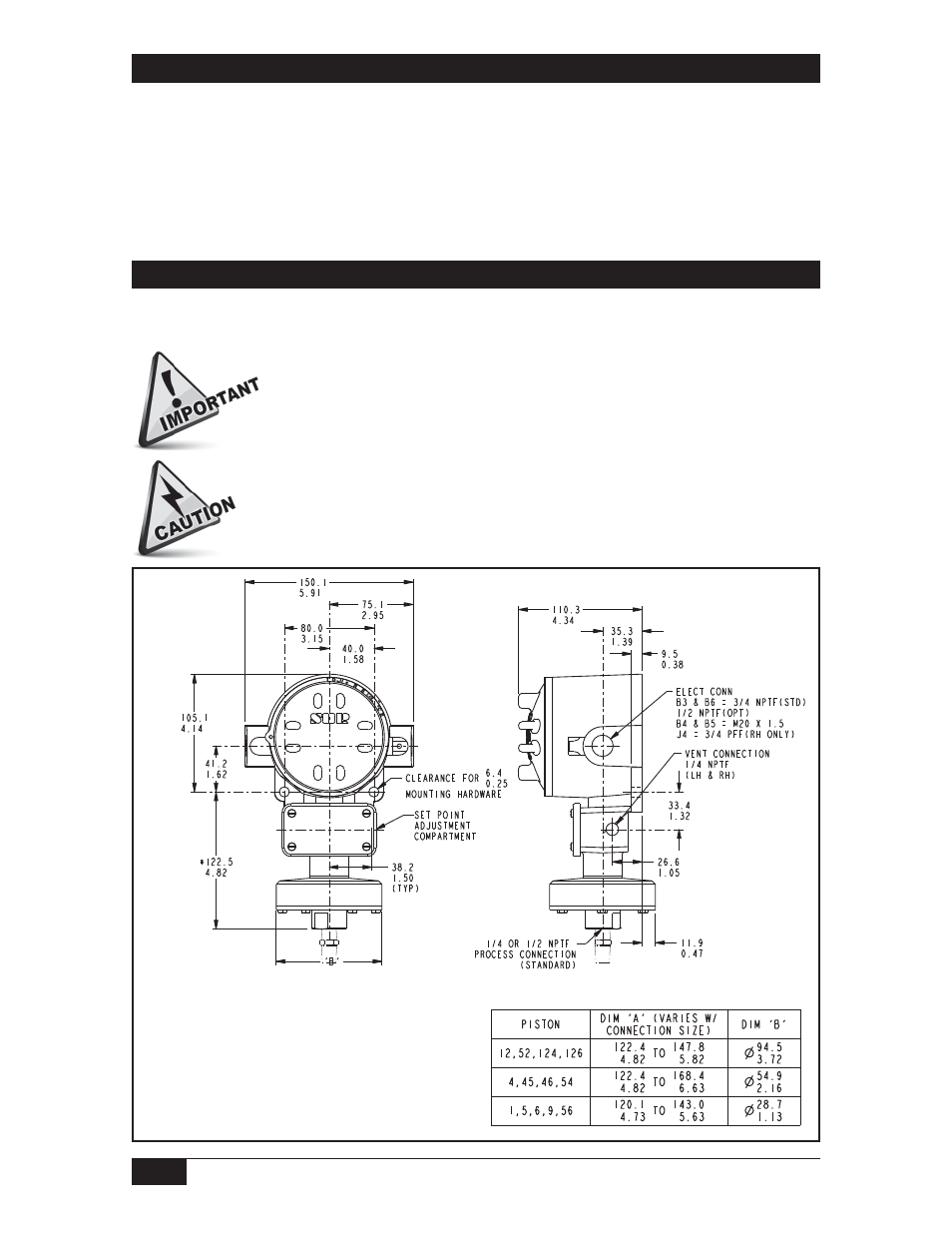

Process Connection

Dimensions are for reference only.

Contact the factory

for certified drawings

for a particular model number.

Linear = mm/inches

Drawing 0091417

Securely connect the process line to the pressure connection using two wrenches; one to hold

the wrench flats on the pressure port, the other to tighten the process pipe or tube fitting.

Ensure that the process connection is tightened and positioned so

that bending and torsional forces imposed on the pressure switch are

minimal. Do not loosen the pressure port from the body or the body from

the housing, because leakage could result or the pressure switch could

be rendered inoperative.

One vent connection should be fi tted with a suitable breather to maintain

weathertight rating NEMA 4, 4X, IP65 or vented to a safe area. Piping

should be minimum 1/4” diameter and maximum 5 meters long (based

on process fl uid SG 1.0). The other vent connection may be plugged.

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration.

Form 1538 (03.12) ©2012 SOR Inc.