Parr Instrument 6725 User Manual

Page 34

6725

Semi-micro Calorimeter Instruction Manual

5-7

User Function Setup:

This key leads to sub menus that support the configuration of five factory/user definable

function keys. The function keys are accessible from the Diagnostics page.

Cold Restart:

This is essentially the same as cycling power on the unit. All valid test data will be

retained during this cold restart procedure.

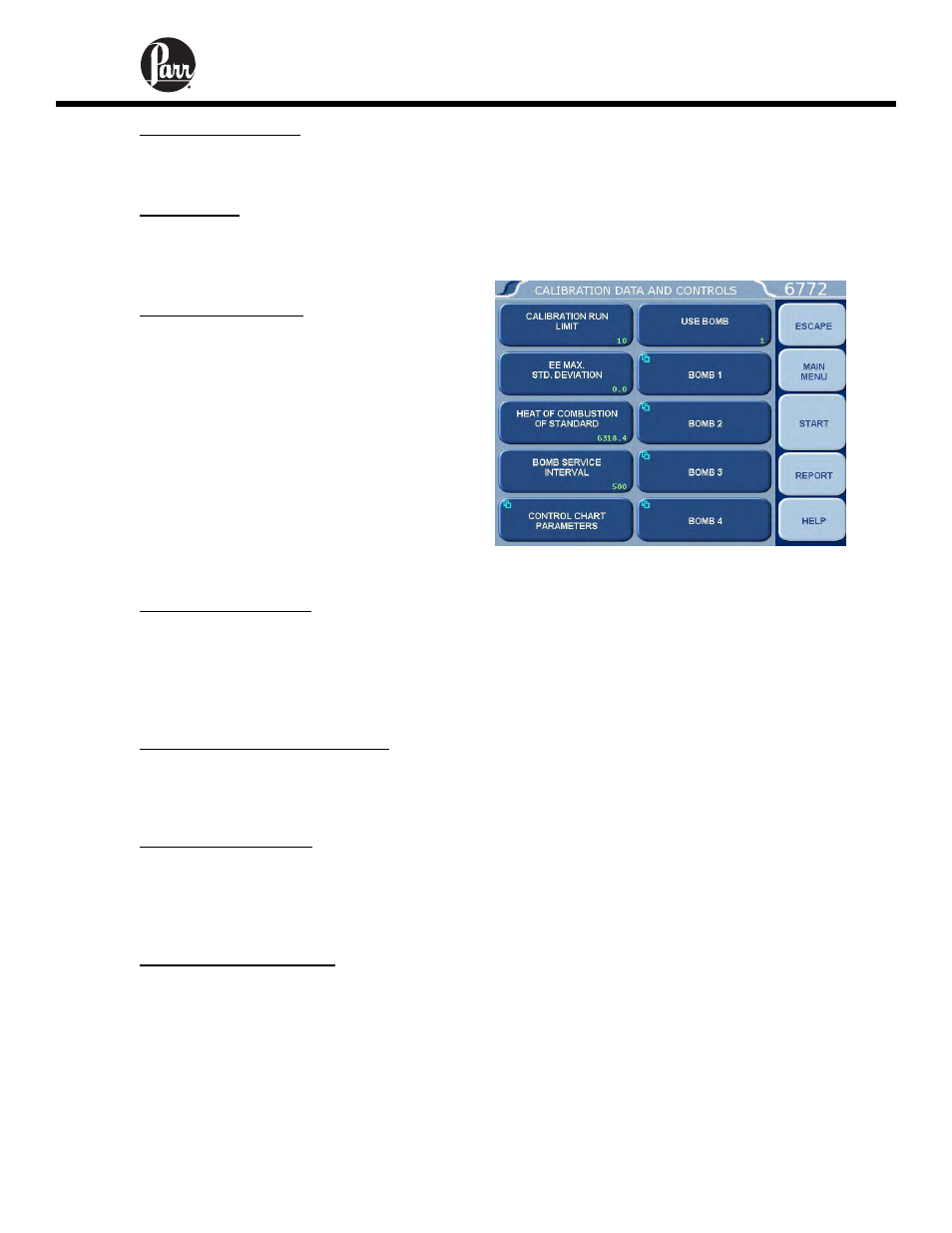

Calibration Data and Controls Menu

Calibration Run Limit:

Displays the maximum number of runs that

will be included in determining the EE value

of a bomb and bucket combination and

accesses the sub-menu on which this limit is

set. Most test methods suggest 10 tests.

Tests in excess of the most recent ones

used are still available but are not used in

the calculation of the EE value. For example

if 11 standardization tests have been run, the

calorimeter will only use the most recent 10.

The 11

th

is still stored in the memory and is

available for view or printing. Only runs that

are at final status will be used in this calculation.

EE Max Std Deviation:

Displays the maximum relative standard deviation in percent that will be

permitted for any EE value calculated by the Calorimetric Thermometer and

accesses the sub-menu on which this limit is set. If this value is exceeded, the

user will be warned to take corrective action before proceeding with testing. A

setting of zero disables this check.

Heat of Combustion of Standard:

Displays the heat of combustion in calories per gram for the material used to standardize

the Calorimetric Thermometer and accesses the sub-menu on which this value is set.

For benzoic acid, this value is 6318.4 calories per gram.

Bomb Service Interval:

Displays the maximum number of times a bomb may be fired before it is flagged as due

for service and accesses the sub-menu on which this limit is set. Parr recommends 500

firings for this service interval. (Parts may need to be replaced on a more frequent basis

depending upon the nature of the sample).

Control Chart Parameters:

A control chart is a graphical tool which can assist the user in determining whether or not

their process is in control. Many standard methods will dictate that a reference sample

be measured periodically and the results plotted on a graph. Limits for acceptable values

are defined and the process is assumed to be in control as long as the results stay within

these limits. Since results are expected to scatter with a normal distribution within

established limits, systematic trends or patterns in the data plots may also be an early

warning of problems.