Kipp&Zonen LAS MkII Scintillometer User Manual

Page 63

63

Instruction Manual - LAS MkII Scintillometer

6.1 Internal calibration features

The LAS MkII receiver has built-in diagnostics and calibration features to ensure correct operation of the system. These

functions can be accessed using the navigation keys and display.

6.1.1 Checking C

n

2

processing

Follow the following steps to check the internal processing of

C

n

2

values.

Main Menu

→ 2. Configuration → 1. Installation → 1. Aperture → set to 152 mm → Confirm Entry: YES

Then; 2. Configuration

→ 1. Installation → 2. Path Length → set to 1184 m → Confirm Entry: YES

Enter the Diagnostics menu and set ‘Gain’ to 10 Hz:

Main Menu

→ 4. Diagnostics → 1. Gain → set to 010 Hz → Confirm Entry: YES

Internally a reference signal is processed with the following characteristics:

Ratio high / low level of pulse

: 2

Scintillation frequency

: 10 Hz

This should yield a

C

n

2

value on the display of 1.0 • 10

-12

m

-2/3

± 0.5 %.

Note

If the result is outside the limits please contact

[email protected] for recalibration.

6.1.2 Electronics offset noise check

The electrical noise of the electronics can be checked as follows:

Main Menu

→ 2. Configuration → 1. Installation → 1. Aperture → set to 152 mm → Confirm Entry: YES

Then; 2. Configuration

→ 1. Installation → 2. Path Length → set to 1184 m → Confirm Entry: YES

Enter the Diagnostics menu and start the ‘Offset’ test:

Main Menu

→ 4. Diagnostics → 2. Offset

This procedure disconnects the detector from the input electronics and the

C

n

2

measured as the result of electronics noise is

displayed. This should be < 1.0 • 10

-17

m

-2/3

.

Note

If the result is outside the limits please contact

[email protected] for recalibration.

After either of these check be sure to return the configuration to the correct operational settings for aperture and

path length.

6.2 Maintenance and inspection intervals

To ensure that the quality of the measurements is of a high standard, care must be taken with the maintenance of the LAS MkII.

Regular cleaning of the transmitter and receiver windows and checking the optical alignment will prevent unnecessary signal

attenuation and data loss. Regularly check the desiccant to prevent moisture inside the transmitter and receiver. Periodically

check the condition of all cables and connectors.

Always keep power connected, and switched on, to the LAS MkII transmitter and receiver when they are placed

outside. The power dissipation helps to prevent internal condensation.

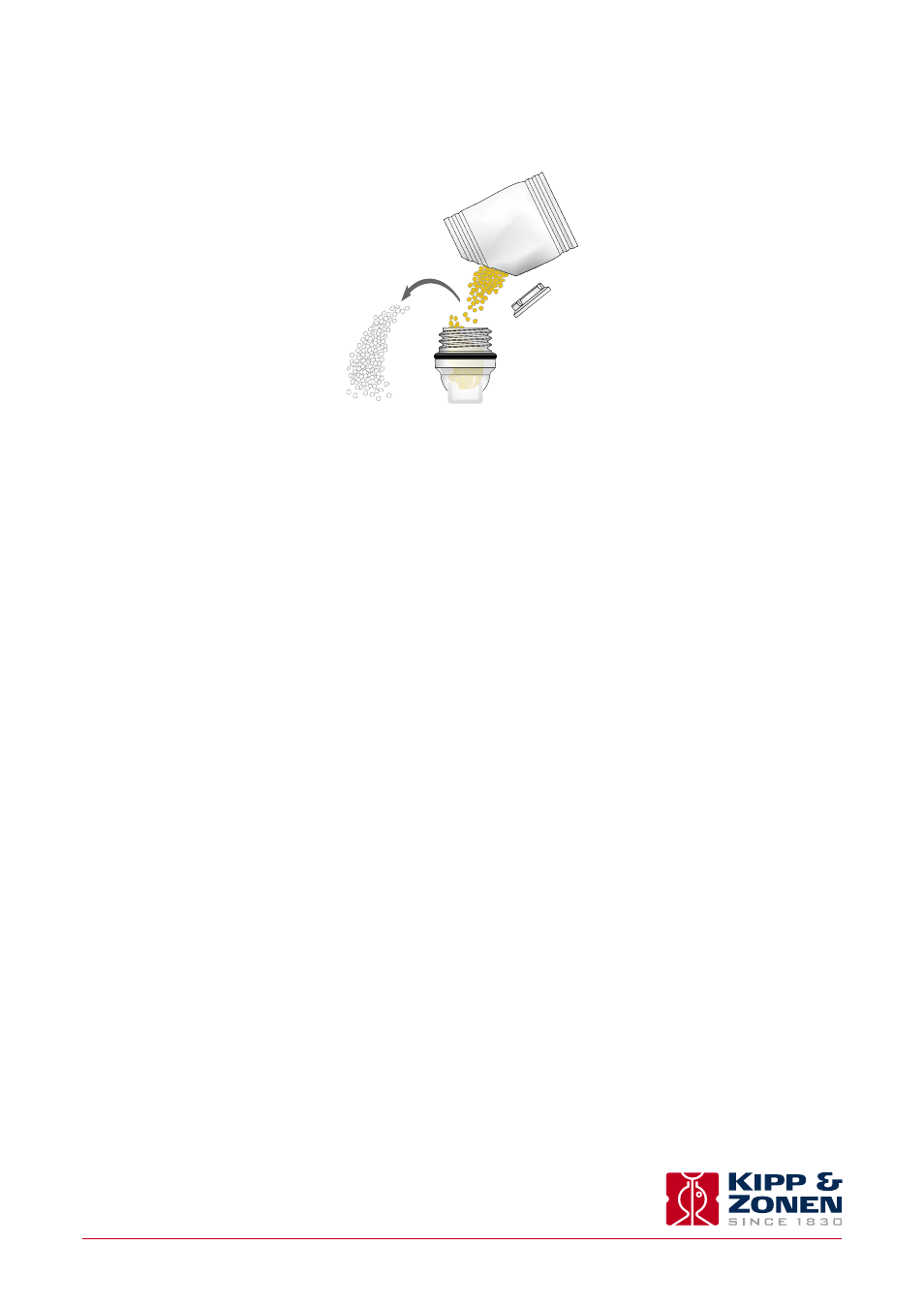

6.3 Inspecting and replacing desiccant cartridge

On a regular basis check the desiccant in the drying cartridges. This is a self-indicating silica-gel. When it requires replacement

the colour changes from orange to clear.

1. Locate the two desiccant cartridges in the undersides of the transmitter and receiver and inspect the colour of the beads. If

they are yellow they do not need replacing. If they are clear and transparent they need replacing with fresh desiccant.

2. To replace the desiccant unscrew the cartridges, if they are tight a 16 mm or 5/8” open-ended wrench / spanner can be used

to loosen them, then unscrew by hand.

.

3. Remove the caps from the ends of the cartridges and safely dispose of the used silica-gel. Refill with fresh desiccant, and refit

the end caps to the cartridges.

4. Make sure that the o-ring seals and their seats in the housing are clean, grease with Vaseline if it they are dry. Refit the drying

cartridges.

Note

Screw in the drying cartridges hand-tight only, to avoid distorting the o-ring seals. Desiccant refill packs are

available from Kipp & Zonen. One pack is sufficient for one cartridge refill.