Selftest procedures, Fault conditions – Hanna Instruments HI 504 User Manual

Page 47

93

92

If the error is due to impossible communication with the

EEPROM or the RTC, all the pH/ORP controller tasks are

stopped, the alarm relay is de-energized, the red LED blinks

and the “Serial bus error” slides forever (repair can not be

postponed).

A software watchdog is provided in order to detect dead loop

conditions or other causes that make the software stuck. If it

happens, a software reset is generated after a time-out of 1

second.

SELFTEST PROCEDURES

The selftest procedure can be made only entering the setup

menu and selecting one of the items of the “tESt” group (t.00

- t.08).

Note

All the tests are made while in setup mode, where a time-out

is present. If no action is performed for about 5 minutes, the

mode is automatically exited and the instruments returns to

previous mode.

DISPLAY TEST

The display selftest procedure consists of lighting up all the

display segments together.

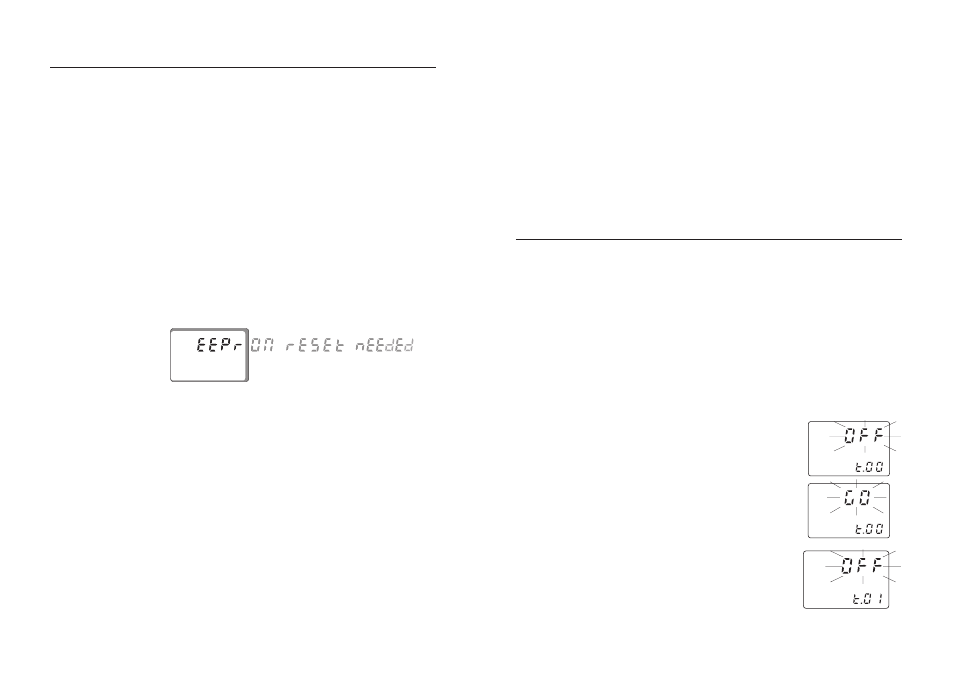

• To start the procedure select setup

item t.00 and an “OFF” blink-

ing message will appear on the

primary LCD.

• Press the

æ (or ) key once and

the message will switch to a blink-

ing “GO”.

• Press CFM key to confirm or the

æ (or ) key again to return to

the previous status.

• If confirmation is given when the

“OFF” message is blinking, no ac-

tion is performed and it will move

to the next setup item (t.01).

FAULT CONDITIONS

The below fault conditions may be detected by the software:

• EEPROM data error

• serial communication internal bus failure

• software dead loop.

EEPROM data error can be detected through EEPROM test

procedure at start-up or when explicitly requested using setup

menu, or during normal operational mode if a checksum

control fails.

When an EEPROM error is detected during normal mode, a

fault alarm is generated according to the user configuration

for the EEPROM corruption error (see “Alarm” section).

To close an error an EEPROM test (see “Selftest procedures”

section) or reset is required.

As soon as an EEPROM error is detected, the scrolling mes-

sage “EEPROM reset needed - Press up button to reset stored

data or right button to ignore” will appear on the primary

LCD.

If the key is pressed, the process controller restarts opera-

tion, but alarm actions are performed as configured by the

user (see “Alarm - Error configuration” section). Note that

the device will be in Hold mode in any case.

If the

æ key is pressed, all the data stored in the EEPROM are

erased and the default values loaded. After that, the device

must be completely recalibrated.

An internal bus error is detected when internal transmission

is not acknowledged or a bus fault occurs for more than a

certain number of unsuccessful transmission attempts (due

for example to a damage occurred to one of the ICs con-

nected to the internal bus). After that the controller displays a

sliding message “Serial bus error”.