Maintenance, 2 draining of boiler heating circuit, 3 igniter unit – Glow-worm Flexicom sx User Manual

Page 39: 4 ignition lead, 5 silencer assembly (front), 6 gas valve, 7 flue hood, 8 fan

0020107231_04 - 12/14 - Glow-worm

MAINTENANCE

- 39 -

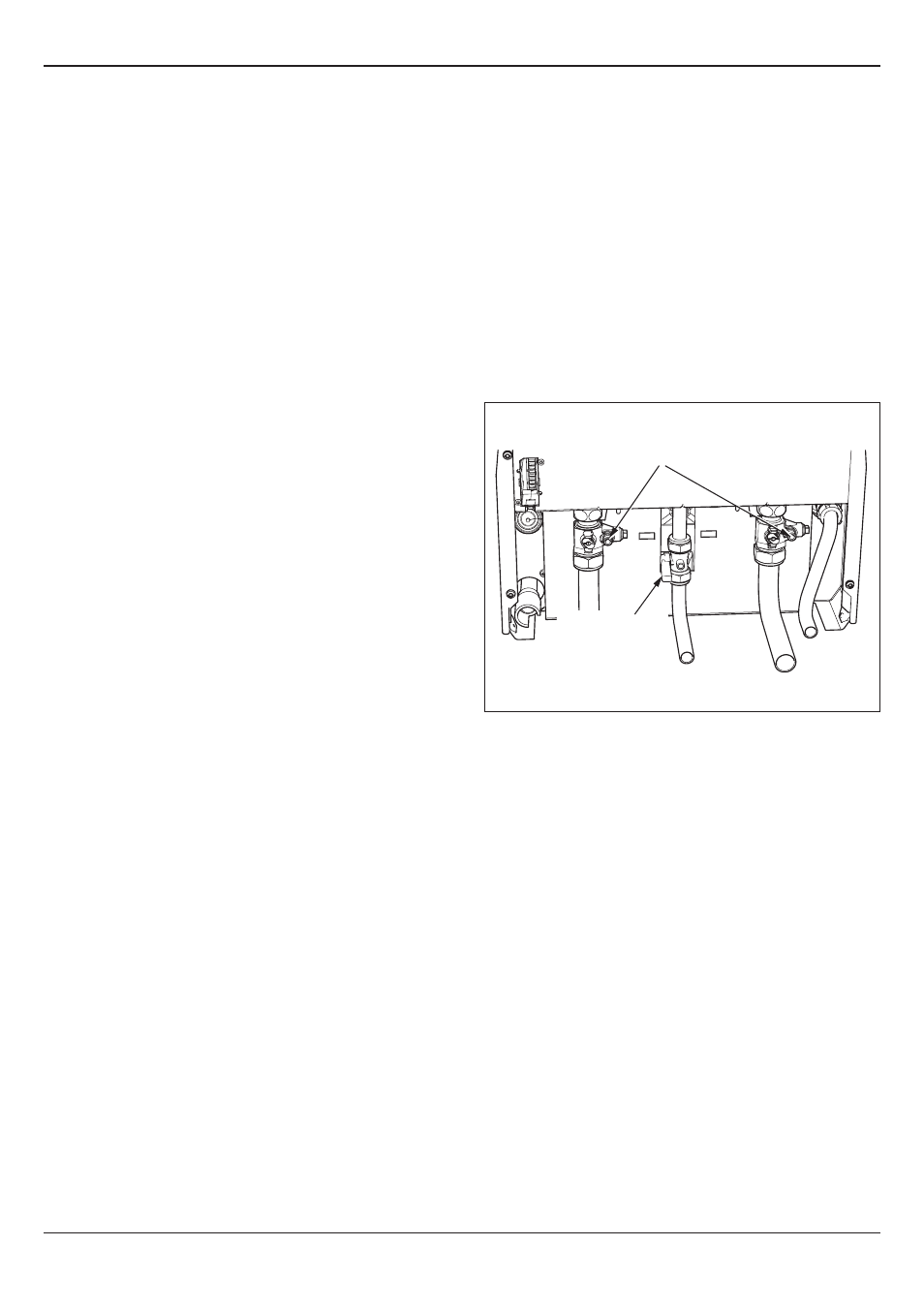

DRAIN POINTS

GAS SERVICE

ISOLATION

VALVE

14 Replacement of Parts

14.1 General

Replacement of parts must be carried out by a

competent

person approved at the time by the Health and Safety

Executive.

Before replacing any parts the boiler should be isolated from

the mains electric supply and the gas should be turned off at the

gas service isolation valve on the boiler, see diagram 14.1.

Ensure that components with electrical connections are

disconnected before removal.

Unless stated otherwise parts are replaced in the reverse order

to removal.

After replacing any parts always test for gas soundness and if

necessary carry out functional test of the controls.

For replacement of parts the front casing of the boiler will

need to be removed. To remove undo the two screws on the

underside of the front casing and lift off.

14.2 Draining of Boiler Heating Circuit

Drain down the Heating Circuit of the boiler only, by closing the

heating flow and return isolating valves on the wall mounting jig.

Attach a length of hose to the drain point and open the drain

valve, see diagram 14.1.

Check for leaks.

14.3 Igniter Unit

For access, refer to section 14.1.

Remove ignition lead and electrical connections then remove

igniter unit by removing two securing screws, see diagram 12.8.

14.4 Ignition Lead

For access, refer to section 14.1.

Pull the spark plug style connector off the spark electrode and

the spade connector connected to the igniter unit, see diagrams

12.5 and 12.8.

14.5 Silencer Assembly (front)

For access, refer to section 14.1.

Pull forwards to remove.

The silencer is a push fit so no tools or fixings are required for

its removal or fitting, see diagram 12.7.

14.6 Gas valve

For access, refer to section 14.1.

Remove the electrical plug from the gas valve.

Undo the tubing nut holding the gas pipe to the gas valve.

Remove the three securing screws, holding the gas valve to the

fan and remove the gas valve, see diagram 12.6.

After re-fitting check the combustion CO2 and adjust if

necessary, refer to section 12 Combustion Check.

After assembly test for gas soundness and purge in accordance

with the current issue of BS6891or in IE, the current edition of

I.S.813 “Domestic Gas Installations”.

Diagram 14.1

13046

14.7 Flue Hood

For access, refer to section 14.1.

Pull the flue hood securing clips away from the flue hood sump

and push flue hood up slightly towards flue hood top, see

diagram 12.4.

To remove swivel flue hood 90° and pull down and out towards

front of boiler, see diagram 12.4.

14.8 Fan

For access, refer to section 14.1.

Remove the gas valve as described in the relevant parts of

section 14.6.

Remove the securing nut holding the fan retaining bracket, lift

front of bracket away from stud and pull forward to release the

fan, see diagram 12.9, check and replace any seals or gaskets

if necessary.