Installation, 6 range rating, 7 testing - heating system – Glow-worm Flexicom sx User Manual

Page 27: 8 completion, 9 instruct the user

0020107231_04 - 12/14 - Glow-worm

INSTALLATION

- 27 -

11.6 Range Rating

These boilers are fully modulating, therefore it is not necessary

to range rate them, however, if desired, you can adjust the

output in 1kW increments between:

18sx : 10 - 18kW

30sx

:

10

-

30kW

as follows:

a) Press and hold the ‘MODE’ and “+” button for 5

seconds. The display will change to flashing ‘0’.

b) Use the ‘+’ or ‘-’ button to scroll to 96.

c) Press ‘MODE’ and hold 5 seconds to confirm.

d) The display now shows a flashing ‘d. 0’.

e) The part load setting is displayed in kW.

Press ‘MODE’ the max rate will be indicated, to

change the value to the desired setting, use the ‘+’

or ‘-’ button.

f) Press ‘MODE’ for 5 sec to confirm the new setting

has been saved.

g) Press and hold ‘MODE’ and “+” to exit.

Please refer to the table below to check the gas rates.

kW

m3/hr

ft3/hr

kW

m3/hr

ft3/hr

20

2.1

74.2

30

3.2

113

19

2.0

70.6

29

3.1

109.5

18

1.9

67.1

28

3.0

106

17

1.8

63.6

27

2.9

102.4

16

1.7

60.0

26

2.8

98.9

15

1.6

56.5

25

2.6

91.8

14

1.5

53.0

24

2.5

88.3

13

1.4

49.5

23

2.4

84.8

12

1.3

45.9

22

2.3

81.2

11

1.2

42.4

21

2.2

77.7

10

1.1

38.9

11.7 Testing - Heating System

Check that all external controls are calling for heat, the boiler

will fire automatically. Fully open all radiator valves and flow

control valve ‘A’, if fitted, see diagram 5.3.

Balance the radiators as required and if fitted adjust valve ‘A’ to

give the required system differential. Turn off all radiators that

can be shut off by the user and check to see if less than the

maximum differential allowed of 20°C can be achieved across

flow and return.

The pump has two speeds and can be adjusted depending on

the requirements of the central heating system, see diagram

5.2.

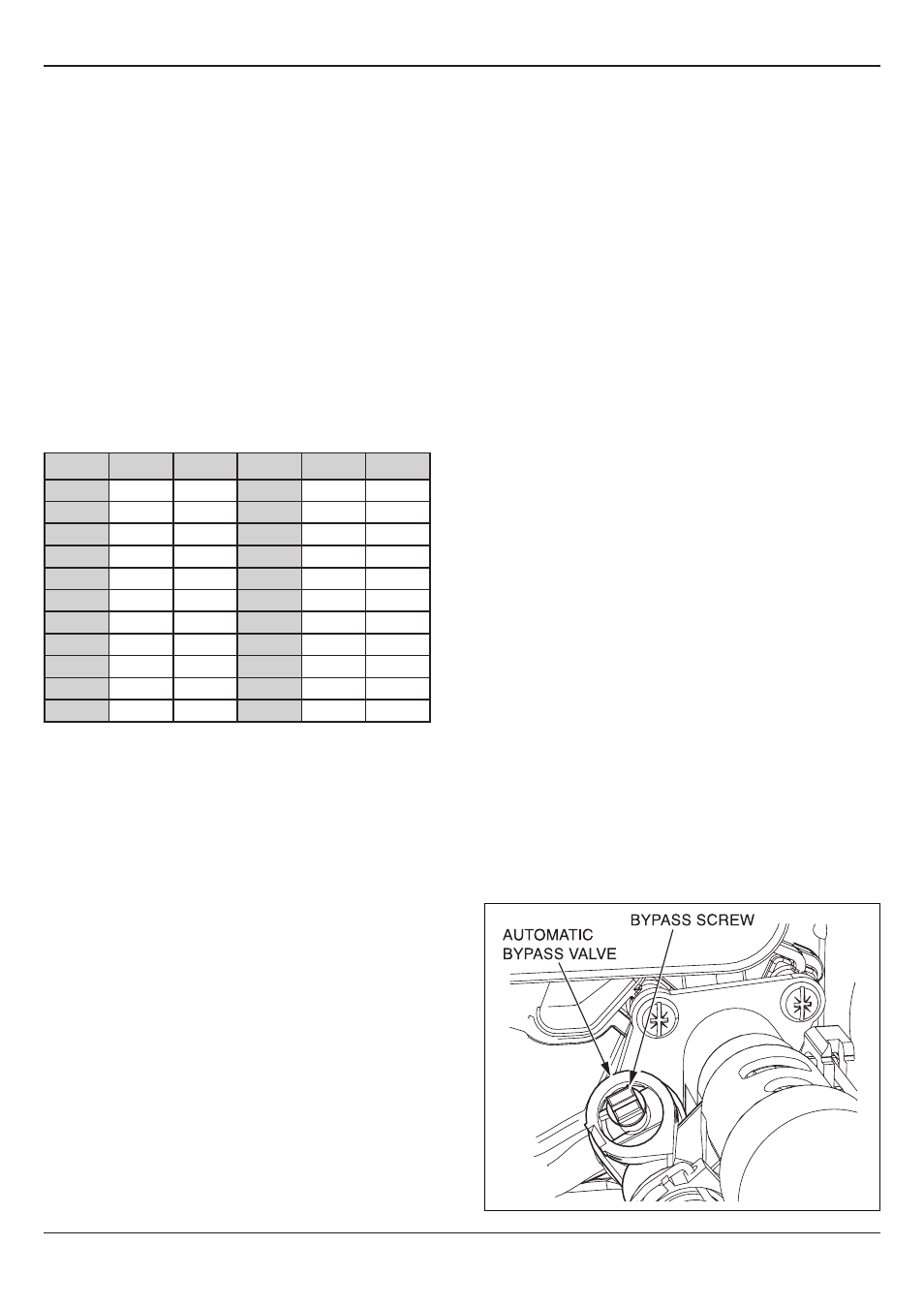

The appliances have an inbuilt automatic adjustable bypass

valve, see diagram 11.4. The pressure can be adjusted between

approx. 1.5 and 3.5mH

2

O.

The bypass is factory pre-set to approx. 2.5mH

2

O. The pressure

changes by approx. 0.1mH

2

O for each full turn of the bypass

screw, see diagram 11.4. Turning clockwise increases the

pressure and turning anti-clockwise decreases the pressure.

Allow the system to reach maximum temperature then switch off

the boiler by isolating from the electrical supply.

Drain the entire system rapidly whilst hot, using the drain tap

at the lowest part of the system. Fill and vent the system as

described previously in section 11.1.

Lock or remove the handle from control valve, if fitted.

11.8 Completion

Adjust the boiler temperature control and any system controls to

their required settings.

GB: It is a requirement that the “Benchmark” Installation,

Commissioning and Service Record is completed and left with

the user.

IE: it is necessary to complete a “Declaration of Conformity” to

indicate compliance to I.S.813. An example of this is given in

the current edition of I.S.813.

11.9 Instruct the User

● Demonstrate, then instruct the User about the lighting

procedure and heating system controls operation.

● Advise that to ensure the continued efficient and safe

operation of the boiler it is recommended that it is checked

and serviced at regular intervals. The frequency of servicing

will depend upon the installation conditions and usage, but in

general, once a year should be enough.

● Draw attention, if applicable, to the current issue of the Gas

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance in the UK.

● The user shall not interfere with or adjust sealed components.

● It is the Law that any servicing is carried out by a

competent

person approved at the time by the Health and Safety

Executive.

● Advise the user that, like all condensing boilers this appliance

will produce a plume of condensation from the flue terminal in

cool weather. This is due to the high efficiency and hence low

flue gas temperature of the boiler.

● Advise the user of the precautions necessary to prevent

damage to the system, boiler and the building, in the event of

the heating system being out of use during frost or freezing

conditions.

● Advise the user that the permanent mains electrical supply

SHOULD NOT be switched off, as the built in frost protection

and pump saver program will not operate.

● Advise the User if the mains electricity and gas are to be

turned off for any long periods during severe weather, it is

recommended that the whole system, including the boiler,

should be drained to avoid the risk of freezing.

NOTE: Sealed System: Contact your installation/servicing

company as draining, refilling and pressurising MUST be

carried out by a

competent person approved at the time by the

Health and Safety Executive.

● Leave these instructions and the ‘Benchmark’ Installation,

Commissioning and Service Record with the user.

13073

Diagram 11.4