Installation – Glow-worm Flexicom sx User Manual

Page 21

0020107231_04 - 12/14 - Glow-worm

INSTALLATION

- 21 -

13943

Diagram 8.2

Diagram 9.1

12667

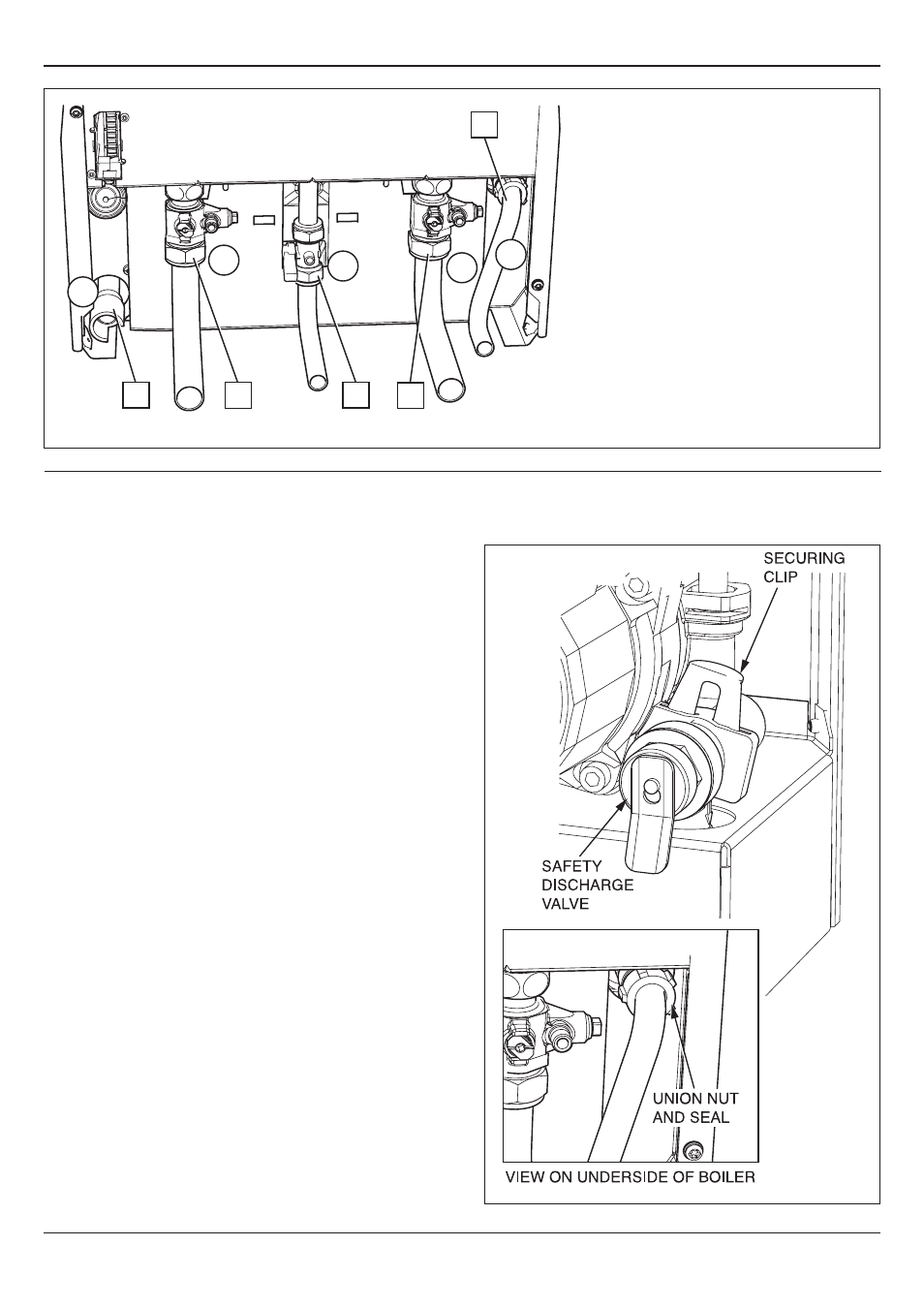

9 Safety Discharge Valve and Condensate

Connections

9.1 Safety Discharge Valve

Take the safety discharge pipe, supplied in the pipe pack and

the union nut and seal, supplied in the loose items pack and fit

as shown in diagram 9.1.

This must be extended, using not less than 15mm o.d. pipe,

to discharge, in a visible position, outside the building, facing

downwards, preferably over a drain.

To ease future servicing it is advisable to use a compression

type fitting to extend the safety discharge valve tube.

The pipe must have a continuous fall and be routed to a

position so that any discharge of water, possibly boiling,

or steam cannot create any danger to persons, damage to

property or external electrical components and wiring.

9.2 Condensate Trap and Siphonic Drain

Connection

A flexible condensate outlet pipe is fitted and should be used

to couple the condensate trap and siphonic drain to a 22mm

to 25mm O.D. non corrosive plastic pipe (overflow pipe), see

diagram 8.2.

IMPORTANT: Please remove the bung from the flexible pipe

before fitting to a drain outlet pipe.

NOTE: the pipe should have a fall of a least 2.5

°

44mm/metre

away from the boiler.

Condensate should, if possible be discharged into the

household internal drainage system. If this is not practicable,

discharge can be allowed into the external household drains or

a purpose designed soak away, refer to diagram 9.2.

It is recommended that any external condensate drain pipe is

protected and also preferably of 32mm diameter, to prevent

freezing in adverse weather conditions.

The condensate is discharged periodically in ‘slugs’ by siphonic

action.

With the exception of combined foul and rain water drainage

systems, it is not necessary to provide air breaks or extra traps

in the discharge pipe as there is already a 75mm high trap

inside the boiler. Fitting an extra trap may cause the boiler

A - Central Heating Isolation Valve

B - Gas Service Isolation Valve

C - Washers (not shown)

D - Condensate Connection

E - Safety Discharge Pipe

Numbers 1 - 5

show the sequence to be used when

tightening to copper tails.

A

B

1

A

D

2

3

5

4

E

siphon to work incorrectly.

Refer to BS5546 or BS6798 for advice on disposal of boiler

condensate.