Caution, Unpacking and assembly, No engine oil – EarthQuake 6040E User Manual

Page 7

Operator's Manual

CRT Models 5040 and 6040E

Check for parts online at

www.getearthquake.com or call 800-345-6007 M-F 8-5 CST

7

unPACkinG And ASSEmBLY

Your rototiller comes fully assembled except for a few parts.

The following instructions will help you unpack your tiller and

assemble and adjust your tiller’s depth regulator lever, cable

tension and handlebar height. You will need - 9/16” wrenches.

unPACk tiLLER

1. Open top of carton and remove handlebar assembly.

. Find parts packet. Parts packet contains:

4- 3/8-16 x 3/4” hex head bolts

4- 3/8-16 locknuts

1- 5/16-18 x 3/4” hex head bolt

1- detent pin

1- five star knob

3. Cut open all corners of carton, lay flat, and remove machine by:

a. Remove two bolts from packing frame.

b. Lift tiller body from frame. DO NOT attempt to remove

the unit by yourself.

inStALL BAttERY Box (6040E)

note: the battery box assembly comes already

mounted on the lower handlebar mount.

1. Remove and discard bolts and nuts that are holding the

battery box assembly to the lower handlebar mount.

Carefully set aside battery box so that wiring remains intact.

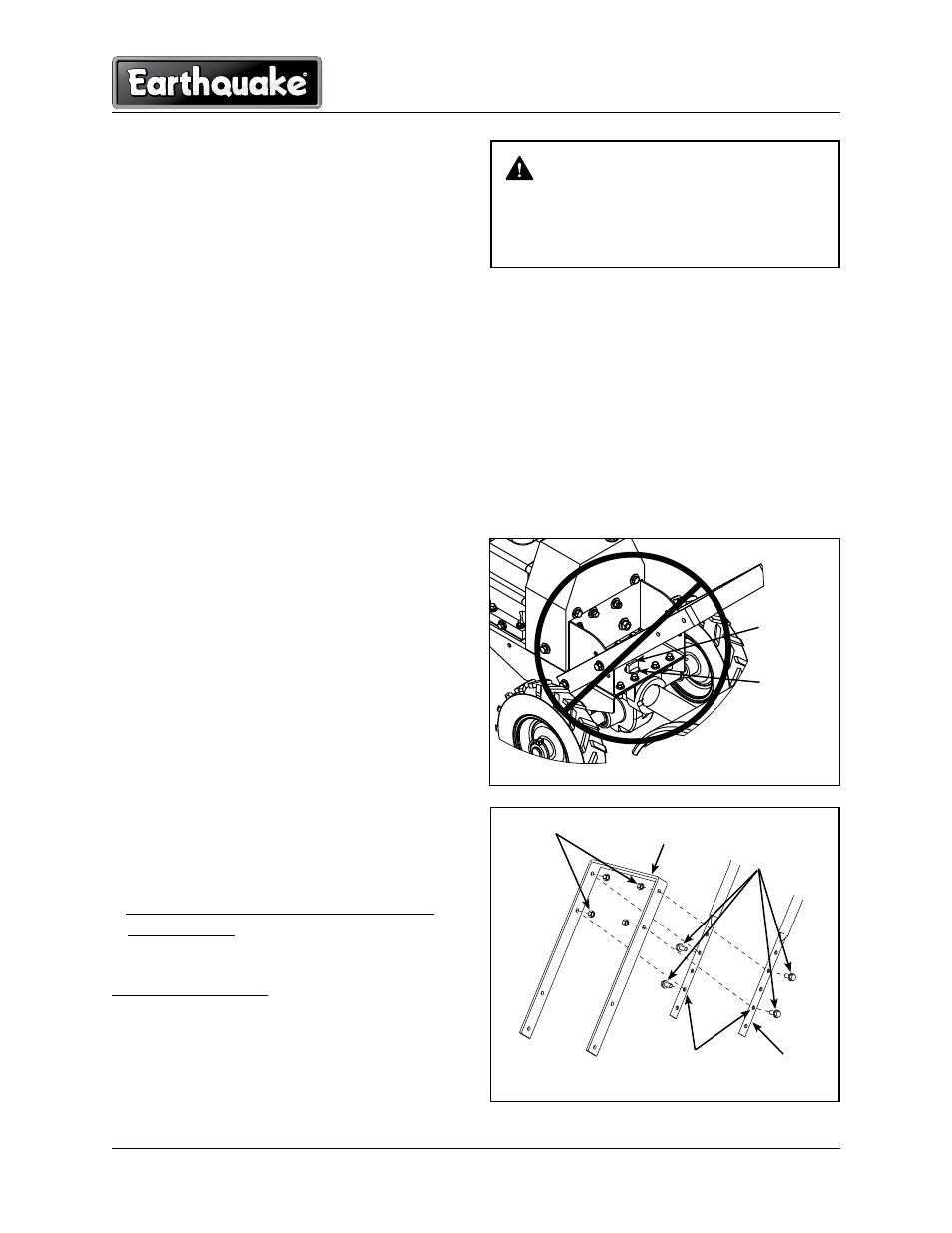

AttACh hAndLEBAR to tiLLER

1. Place handlebar stems on outside of lower handlebar

mount and align lower holes. (SEE FiGuRE 1)

. Insert one 3/8-16 x 3/4” bolt for each side in lower holes

at the desired handlebar height.

3. Start 3/8-16 nuts on each bolt.

4. Insert one 3/8-16 x 3/4” bolt for each side in upper holes.

5. Start 5/16” washers and 3/8-16 nuts on each bolt.

6. Place notches of battery box support over the four bolts

between lower handlebar mount and nuts.

7. Tighten all 3/8-16 nuts.

8. Remove the battery box cover and plug the white plastic

connector from the battery into the mating white plastic

connector in the battery box. Make sure the ignition

key is removed from the ignition before connecting the

wiring for the battery. Replace battery box cover.

height

adjustment

holes

lower handlebar

mount

3/8-16

nuts

3/8-16 x 3/4”

bolts

handlebar

stem

figure 1

CauTion

DO NOT TRY TO LIFT THE ROTOTILLER FROM

THE CARTON.

DO NOT ADD ENGINE OIL INTO GEAR CASE

DIPSTICK HOLE.

gear case

dipstick

gear case

dipstick hole

no EnGinE oiL!

9. PRoPER BELt tEnSion iS CRitiCAL to Good

PERFoRmAnCE.

After 1/ hour of operation, all cables

may have to be adjusted due to initial stretch. Thereafter,

check tension after every hours of operation.

to increase belt tension: (SEE FiGuRE 5 on PAGE 13)

1. Loosen upper jam nut. Turn nut up cable in 1/8”

increments.

. Tighten lower jam nut.

3. Check adjustment.

This procedure can be repeated until conduit adjust-

ment bolts are fully adjusted. If no more adjustment can

be made, belt may have to be replaced.

FiLL EnGinE CRAnkCASE

1. Add oil according to engine manual. Do not overfill. Use

a clean, high quality detergent oil. Container must be

marked A.P.I. Service SF - SJ. Use no special additives with

recommended oils. Do not mix oil with gasoline. Oil level

must be full. Check the oil level by removing oil fill plug. Oil

level should be up to the bottom of the fill plug opening.

. Always check oil level before starting engine. Refer to

engine manual for capacity and type of oil to use.

AttACh WhEELS

1. Slide wheels onto axles.

. Insert lock pin into hole in axle.