Important – EarthQuake 6040E User Manual

Page 17

Operator's Manual

CRT Models 5040 and 6040E

Check for parts online at

www.getearthquake.com or call 800-345-6007 M-F 8-5 CST

17

EnGinE mAintEnAnCE

Refer to the engine manual included in your parts

packet for information on engine maintenance. Your

engine manual provides detailed information and a

maintenance schedule for performing the following

tasks:

1. Check oil level before each use or after every 8 hours

of operation.

. Change oil after first 5-8 hours of operation. Change

oil while engine is warm. Refill with new oil of recom-

mended grade.

4. Check spark plug yearly or every 100 hours of opera-

tion.

5. Service air cleaner.

6. Keep engine and parts clean.

7. Check engine and equipment often for loose nuts

and bolts, keep these items tightened.

ChECk oR FiLL EnGinE CRAnkCASE

1. Add oil according to engine manual. Do not overfill.

Use a clean, high quality detergent oil. Container

must be marked A.P.I. Service SF - SJ. Use no special

additives with recommended oils. Do not mix oil with

gasoline. Oil level must be full. Check the oil level by

removing oil fill plug. Oil level should be up to the

bottom of the fill plug opening.

. Always check oil level before starting engine. Refer to

engine manual for capacity and type of oil to use.

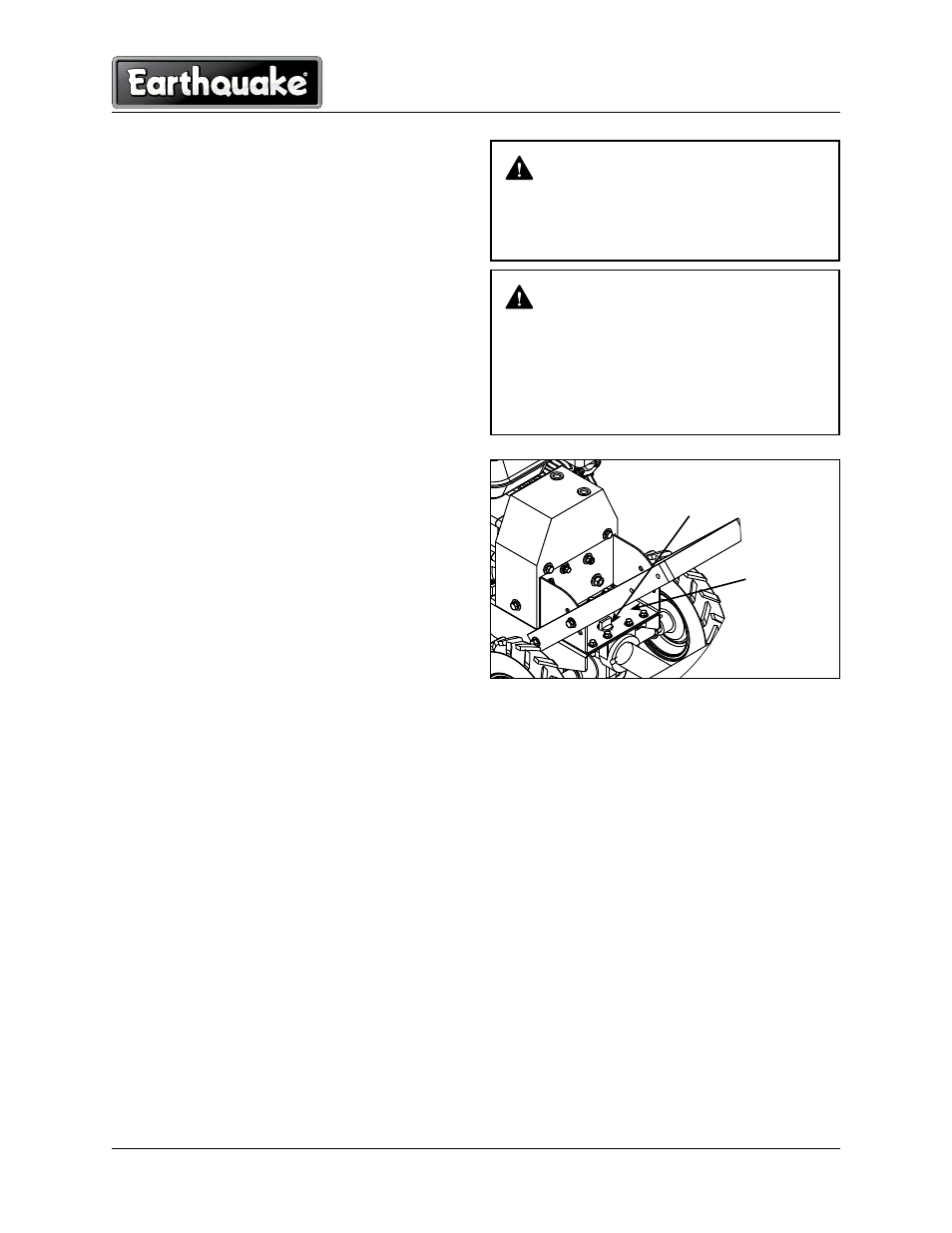

ChECk tiLLER tRAnSmiSSion GREASE

Check the grease level annually. To check the grease

level:

1. Move tiller to level ground.

. Remove grease level dipstick located between the

handlebar mounts on the engine mount. Correct

grease level is indicated between the high and low

levels on the dipstick.

3. Replace grease level dipstick in the filler hole.

4. Note that the front wheel transmission and rear tine

transmission are one common reservoir. When you

add to the front transmission, you must wait a short

period of time for the grease to flow rearward and

equalize in both front and rear. The dipstick will read

correctly on level ground for both gear units.

(Use Mystic 00 transmission fluid PN1690)

ChECk tiRE PRESSuRE

Recommended tire pressure is 0 PSI. If tires do not have

equal pressure, tiller will pull to one side.

iMpoRTanT

EnGinE iS ShiPPEd FRom FACtoRY With-

out oiL. You muSt Add EnGinE oiL BEFoRE

StARtinG EnGinE.

iMpoRTanT

tiLLER tRAnSmiSSion iS ShiPPEd FRom

FACtoRY With thE PRoPER Amount oF

Liquid GREASE.

WhEn REPLACinG GREASE, thE tiLLER tRAnSmiS-

Sion hoLdS 18-22 ounCES. do not oVERFiLL.

gear case

dipstick

transmission

cover plate