Dunkirk Helix VX Vertical Laser Tube Wall Hung Stainless Steel Modulating Condensing Boiler User Manual

Page 84

84

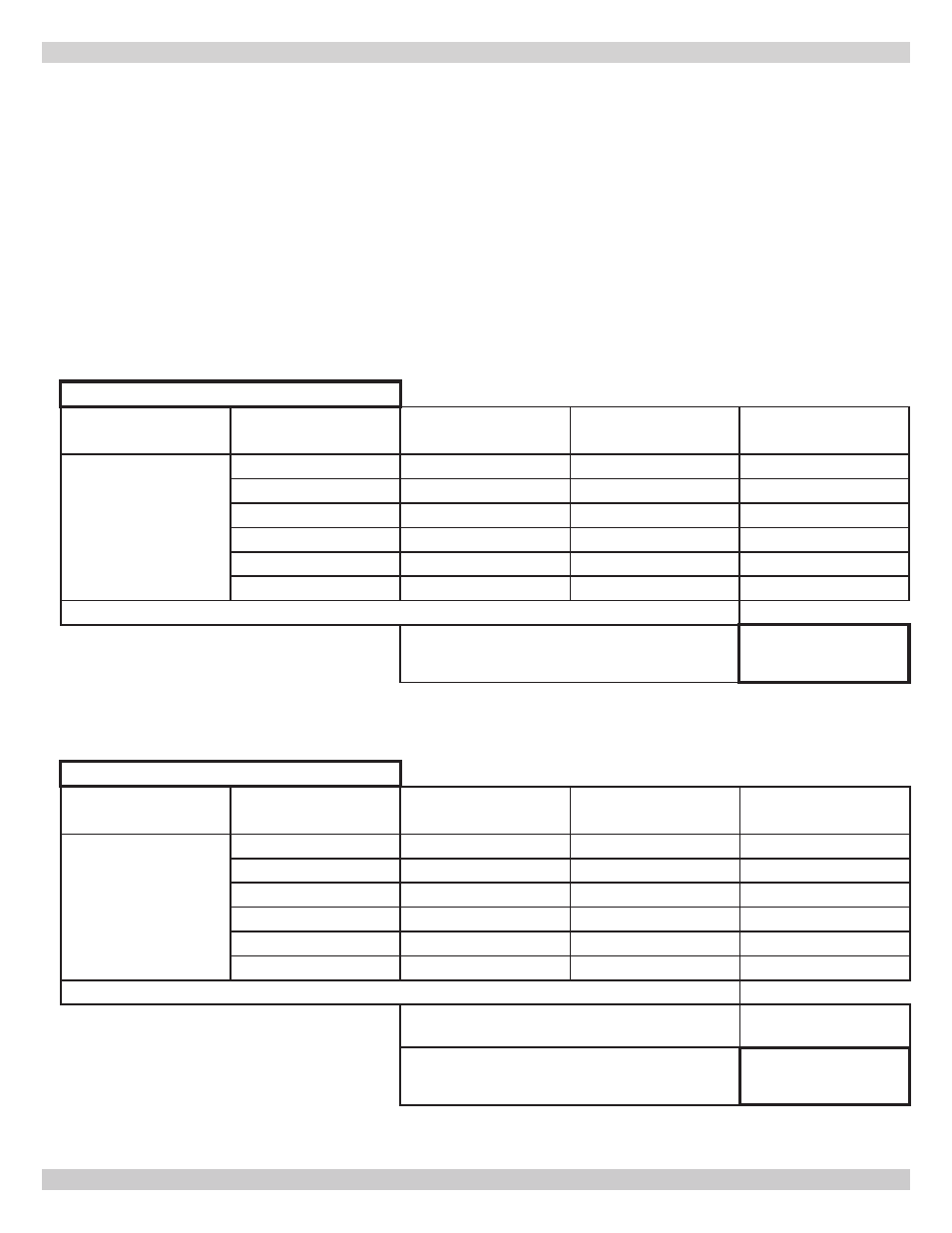

50/75/100 MBH - PRIMARY LOOP EQUIVALENT LENGTH CALCULATION & PUMP SELECTION

For 50/75/100 MBH Boilers

(This boiler must be piped with a primary loop)

These charts are valid for piping diagrams on pages 17 & 18

Instructions:

1.

Pipe diameter determines pump size. Smaller the diameter of pipe, larger the pump. 50/75/100 Mbh boilers can be

piped in 3/4" , 1" or 1¼" pipe. Use charts 1-4 to determine pipe size and respective pump size.

2.

Fill in chart using the 3/4" section first. Then consult chart 4 for pump selection.

3.

Pump size may be decreased by decreasing equivalent length of pipe. Use larger diameter pipe as primary loop to

decrease equivalent length. Use chart 2 or 3.

Note: The figures below are based on industry average. Consult valve/fitting manufaturer for exact equivalent length or

for fittings not shown below.

Chart 1

A

B

C

Pipe Diameter

Fitting

Enter Number Of

Fittings

Multiply By

Equivalent Length

A x B

3/4"

90° Elbow

1.875

45° Elbow

1

Tee-branch

3.75

Tee-through

1.25

Swing check valve

6.25

Lift check valve

37.5

Enter Total 3/4" straight pipe length in feet

Add up numbers in column C

Total equivalent length of Primary

Pump Factor

Chart 2

A

B

C

Pipe Diameter

Fitting

Enter Number of

Fittings

Multiply By

Equivalent Length

A x B

1"

90° Elbow

1.875

45° Elbow

1

Tee-branch

3.75

Tee-through

1.25

Swing check valve

6.25

Lift check valve

37.5

Enter Total 1" straight pipe length in feet

Add up numbers in column C

Total equivalent length of Primary

Multiply Total of Column C in Chart 2 by 0.26

Pump Factor