Caution, Notice – Dunkirk Helix VX Vertical Laser Tube Wall Hung Stainless Steel Modulating Condensing Boiler User Manual

Page 32

32

7.1 General

• Use piping materials and joining methods acceptable

to authority having jurisdiction. In absence of such

requirements:

• USA - National Fuel Gas Code, ANSI Z223.1/NFPA

54

• Canada - Natural Gas and Propane Installation Code,

CAN/CSA B149.1

• Size and install gas piping system to provide sufficient

gas supply to meet maximum input at not less than

minimum supply pressure. See Table 8.

• Support piping with hooks straps, bands, brackets,

hangers, or building structure components to prevent or

dampen excessive vibrations and prevent strain on gas

connection. Boiler will not support piping weight.

• Use thread (joint) compound (pipe dope) suitable for

liquefied petroleum gas.

• Install manual main shutoff valve outside of jacket. See

figures 7-1A and 7-1B.

7.2 Conversion Kit Instructions

• See Gas Conversion Kit Instructions included with Boiler.

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

!

Gas Supply Pressure

MODEL

Natural Gas

Propane

Min.

Max.

Min.

Max.

050

3.0" w.c.

(0.7 kPa)

13.5" w.c.

(3.3 kPa)

5.0" w.c.

(1.2 kPa)

13.5" w.c.

(3.4 kPa)

075

100

150

200

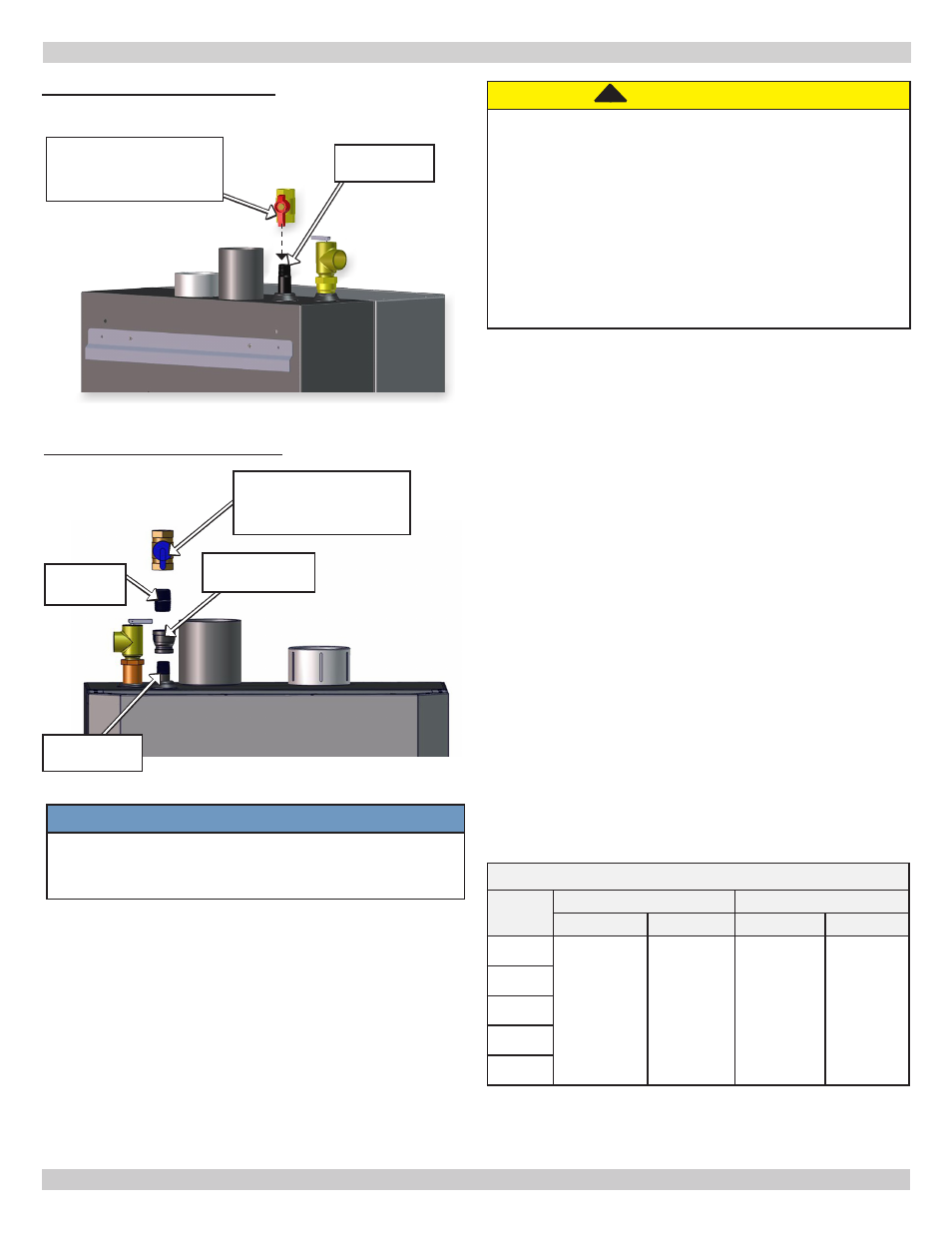

FIGURE 7-1A Gas Connection (at top of Boiler)

50/75/100 Shown

Note: See Glossary - Piping Table 14

NOTICE

Use two (2) wrenches when tightening boiler

fittings and pipes. Boiler's internal piping can be

damaged if subjected to excessive torque.

7 - GAS SUPPLY PIPING

Table 8 - Gas Supply Pressure

FIGURE 7-1B Gas Connection (at top of Boiler)

150/200 Shown

Gas

Connection

Attach Supplied Gas

Shutoff Valve (shown

in open position)

Attach Supplied Gas

Shutoff Valve (shown

in open position)

Gas

Connection

1/2"x 3/4"

Increaser

3/4"

Nipple