Warning – Dunkirk Helix VX Vertical Laser Tube Wall Hung Stainless Steel Modulating Condensing Boiler User Manual

Page 14

14

• Individual boiler discharge piping shall be independent

of other discharge piping.

• Size and arrange discharge piping to avoid reducing

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

• Run pipe as short and straight as possible to location

protecting user from scalding and properly drain

piping.

• Install union, if used, close to safety relief valve outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

• Arrange piping to prevent water dripping onto boiler.

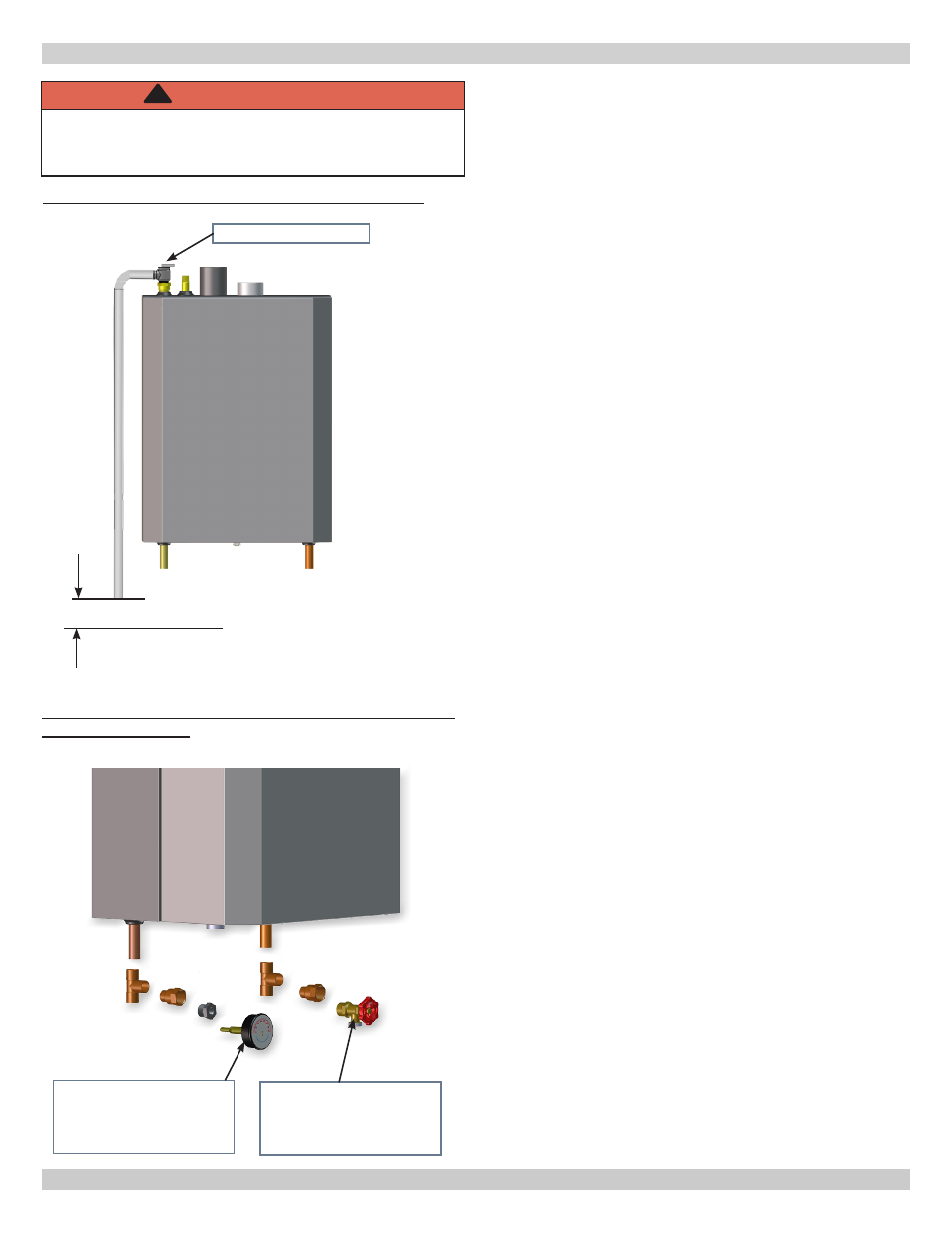

5.4 Trim Piping

• Temperature - Pressure Gauge. Install temperature

pressure gauge using adapter, tee and bushing provided

with boiler. See figure 5-3.

• Protect chassis grommets from heat damage while

soldering.

• Drain Valve. Install drain valve using, tee and adapter

provided with boiler. See figure 5-3.

5.5 System Piping

• See Table 3 for basic system piping configurations.

• Systems with automatic fill valves require back flow

prevention device.

• Single boiler system. See figures 5-4A, 5-5, 5-6, 5-7A & B

for general guidance. Additional considerations:

• Boiler control is designed for single central heating

pump. Installer responsible for integration of

multiple central heating pumps.

• Boiler control allows domestic hot water

prioritization. Function could be lost if central

heating pump not directly connected to control

system.

• Multiple boiler system. See figures 5-8A, B & C for

general guidance. Additional considerations:

• Control system requires equivalent water

temperatures entering each boiler to properly

sequence and adjust system supply temperature.

• Install multi boiler sensor kit. See "Parts, Kits &

Optional Accessories" manual for part number.

• Low Water Cutoff (LWCO) probe location. See figures

5-4A for minimum probe height. Do not install shutoff

valve between boiler and LWCO probe.

• If boiler is below radiation level, use figure 5-4A.

Boilers above radiation level use figures 5.4B thru

5.4D.

• If using separate stand pipe, install air vent using

tee to avoid nuissance shutdowns.

• See figures 5-4B, 5-4C and 5-4D for suggested

probe location alternatives.

• Arrange piping to prevent water dripping onto boiler.

FIGURE 5-3 Temperature Pressure Gauge and Drain

Valve Installations

Temperature Pressure

Gauge shown at

System Supply

Connection

Check Local Codes

For Maximum

Distance To Floor

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Install discharge piping per these instructions.

!

FIGURE 5-2 Safety Relief Valve Discharge Piping

Drain Valve shown

at System Return

Connection to Boiler

Safety Relief Valve

5 - HYDRONIC PIPING