Caution, Notice, Danger – Dunkirk Helix VX Vertical Laser Tube Wall Hung Stainless Steel Modulating Condensing Boiler User Manual

Page 43

43

11.1 Beginning of Each Heating Season

• Check boiler area is free from combustible materials,

gasoline, and other flammable vapors and liquids.

• Visually inspect combustion air and vent piping for

proper operation. Check for and remove any obstruction

to flow of combustion air or vent gases. Immediately

repair or replace pipe showing deterioration or leakage.

Reassemble per instructions in section 6. Ensure proper

reassembly and resealing of system.

• Visually inspect condensate drain line for proper

operation. Checking for deteriorated or plugged

condensate drain line. Verify condensate trap drains

freely.

• Test safety relief valve for proper operation. Refer to

valve manufacturer's instructions packaged with relief

valve.

• Examine flue passages in heat exchanger, burner,

condensate lines, and clean (if necessary) by following

instructions in “Annual Examination and Cleaning of Boiler

Components” in this section.

• Combustion air blower motor furnished with boiler are

permanently lubricated from factory and require no

further lubrication. Lubricate field sourced pumps and/or

motors according to pump and/or motor manufacturer’s

instruction.

• Check following components are operating properly and

are free of blockages or obstructions:

• system air vent;

• check venturi air inlet for blockage and clean as

required;

• verify pressure test port cap and combustion test port

are in place;

• return temperature sensor clip must be securely

seated on pipe; Check boiler for any sign of leaks.

• Check field sourced low water cutoff according to relief

valve manufacturer instructions.

• Check flame signal with user interface. Flame signal

should be 6.5

micro amps or higher at 100% firing rate

( High fire). Flame signal should be 3.3 micro amps or

higher at 1% (low fire).

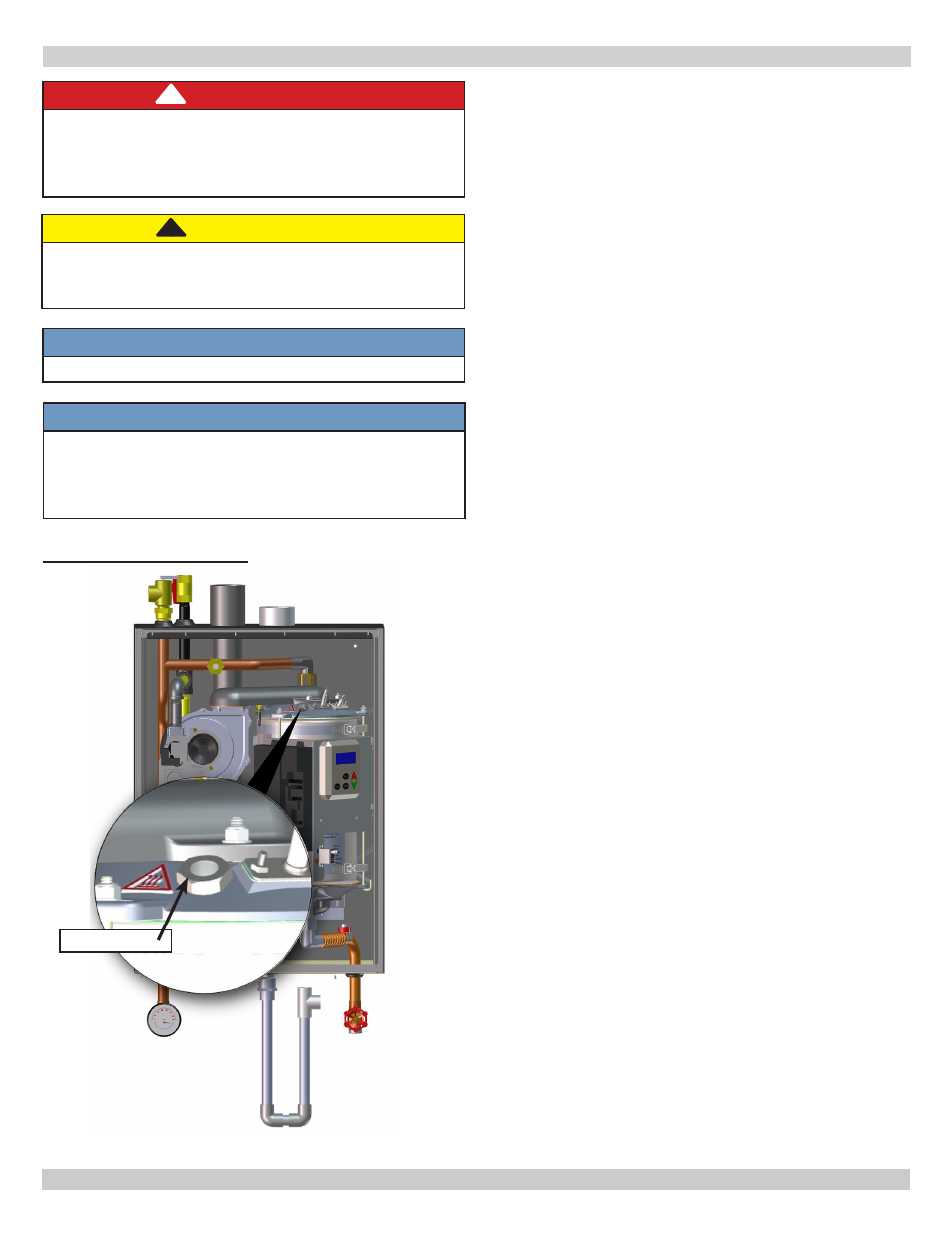

• Visual inspection of flame through sight glass. Burner

should be fully illuminated. See

figure 11-1.

• Check heating system expansion tank.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

!

NOTICE

Verify proper operation after servicing.

NOTICE

Perform regular service and maintenance by

qualified service agency at least once every 12

months to assure safe, trouble free operation and

maximum efficiency.

DANGER

Before servicing, turn off electrical power to boiler

at service switch. Close manual gas valve to turn

gas supply OFF to boiler. Failure to comply will

result in death or serious injury.

!

11 - GENERAL MAINTENANCE AND CLEANING

Sight Glass

Shown 50/75/100 Model

FIGURE 11-1 Sight Glass -