Notice, Warning – Dunkirk Helix VX Vertical Laser Tube Wall Hung Stainless Steel Modulating Condensing Boiler User Manual

Page 13

13

5.1 General

• Install piping in accordance with authority having jurisdiction.

NOTICE

Use two (2) wrenches when tightening boiler's

fitting and pipes. Boiler's internal piping can be

damaged if subjected to excessive torque.

• Support system piping and safety relief valve discharge

piping. Boiler's internal piping and wall mount bracket can

be damaged if subjected to excessive weight.

• Size central heating pump (and domestic hot water pump, if

used) for system requirements only.

• Thoroughly clean and flush system before connecting to

boiler.

• If oil is present in system water, use approved detergent to

wash system.

• Flush system to remove any solid objects such as metal

chips, fibers, or Teflon tape, etc.

5.2 Special Conditions

• System piping exposed to freezing conditions: Use

inhibited propylene glycol solutions certified by fluid

manufacturer for use with closed water heating system.

Do not use automotive or ethylene glycol.

• Boiler used in connection with refrigeration system.

Install piping in parallel with boiler, with appropriate

valves to prevent chilled medium from entering boiler.

• System piping connected to heating coils located in air

handling unit exposed to refrigerated air circulation. Install

flow control valves or other automatic means to prevent

gravity circulation of boiler water during cooling cycle.

5.3 Safety Relief Valve

NOTICE

Boiler rated at 150 psig (1.03 MPa) maximum

allowable working pressure. Boiler provided with 30

psig (206 kPa) safety relief valve. Field source safety

relief valve for system pressures greater than 25 psig.

Temperature Pressure Gauge satisfactory for 60 psig

operation. Field source temperature pressure gauge

for system pressures greater than 60 psig.

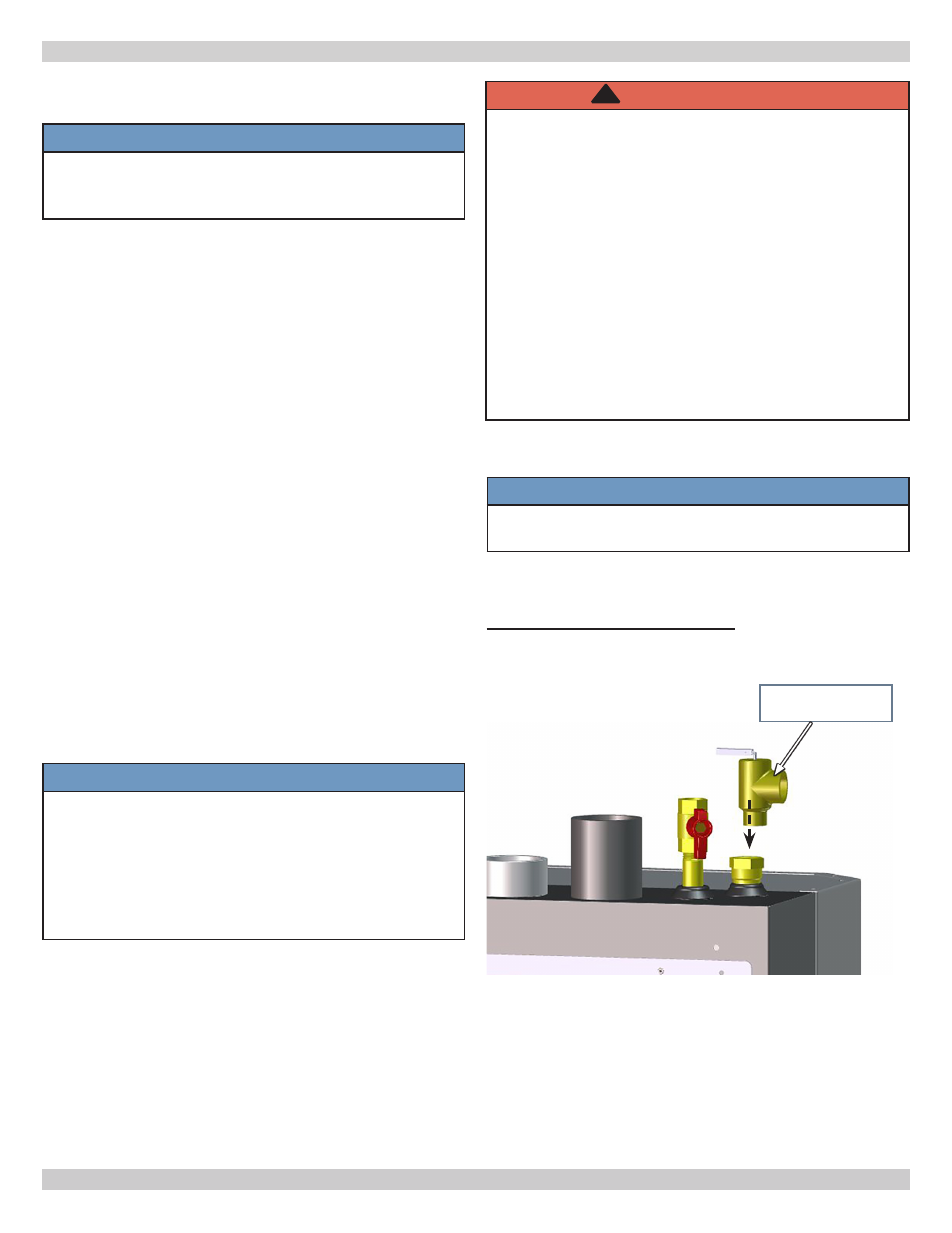

• Install safety relief valve. See figure 5-1

• Install safety relief valve with spindle in vertical position.

• Do not install shutoff valve between boiler and safety

relief valve.

• Install discharge piping from safety relief valve. See

figure 5-2.

• Use ¾" or larger pipe.

• Use pipe suitable for temperatures of 375°F (191°C)

or greater.

WARNING

• Poison hazard. Ethylene glycol is toxic. Do not

use ethylene glycol.

• Never use automotive or standard glycol antifreeze,

even ethylene glycol made for hydronic systems.

• Ethylene glycol can attack gaskets and seals used

in hydronic systems.

• Use only inhibited propylene glycol solutions

certified by fluid manufacturer as acceptable for

use with closed water heating system.

• Thoroughly clean and flush any system that used

glycol before installing new Boiler.

• Provide user with Safety Data Sheet (SDS) on fluid

used.

!

NOTICE

Do not expose boiler and condensate piping to

freezing temperatures.

FIGURE 5-1 Safety Relief Valve (Viewed from rear of

boiler)

Safety Relief

Valve

Position Safety Relief Valve to provide

space for discharge piping.

5 - HYDRONIC PIPING

Shown 50/75/100 Model