Step 6 — install accessories, Step 7 — complete electrical connections – Carrier 38AUZ User Manual

Page 9

9

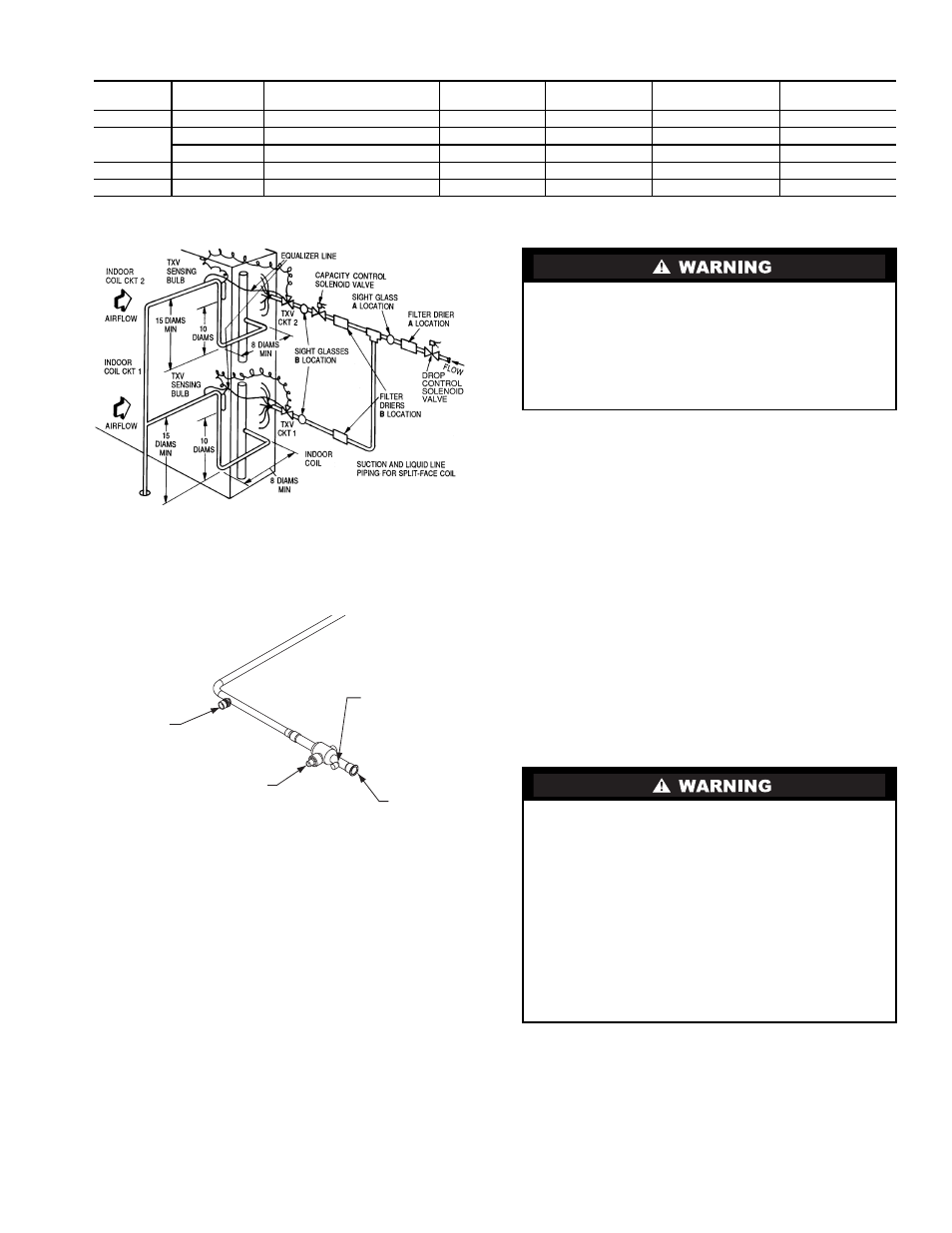

Table 4 — Refrigerant Specialities Part Numbers.

Fig. 5 — Location of Sight Glass(es)

and Filter Driers

Fig. 6 — Typical Piping Connection Assembly

Pressure-test all joints from outdoor unit connections over to

the evaporator coil, using nitrogen as pressure and with soap-

and-bubbles.

When pressure-testing is completed, remove the nitrogen

source at the outdoor unit service valves and re-install the two

Schrader valve cores. Torque the cores to 2-3 in-lbs (23-34

N-cm).

EVACUATION/DEHYDRATION — Evacuate and dehydrate

the connected refrigeration system (excluding the 38AU unit)

to 500 microns using a two-stage vacuum pump attached to the

service ports outside the 38AU service valves, following de-

scription in GTAC II, Module 4, System Dehydration.

PRELIMINARY CHARGE — Before starting the unit, charge

R-410A liquid refrigerant into the high side of the system

through the liquid service valve. The amount of refrigerant

added must be at least 80% of the operating charge listed in the

Physical Data table (Tables 1A and 1B, pages 4 and 5) LESS

the factory charge quantity (if factory shipping charge has not

been removed). Allow high and low side pressures to equalize.

If pressures do not equalize readily, charge R-410A vapor

(using special service manifold with expansion device) into the

suction line service port for the low side of system to assure

charge in the evaporator. Refer to GTAC II, Module 5,

Charging, Recover, Recycling, and Reclamation for liquid

charging procedures.

Step 6 — Install Accessories

Accessories requiring modifications to unit wiring should be

completed now. These accessories may include Winter Start

controls, Low Ambient controls, phase monitor, Compressor

LOCout. Refer to the instructions shipped with the accessory.

Step 7 — Complete Electrical Connections

NOTE: Check all factory and field electrical connections

for tightness. Field-supplied wiring shall conform with the

limitations of 63°F (33°C) rise.

Field Power Supply —

If equipped with optional Powered Convenience Outlet: The

power source leads to the convenience outlet's transformer

primary are not factory connected. Installer must connect these

UNIT

LIQUID LINE

SIZE (in.)

LIQUID LINE

SOLENOID VALVE (LLSV)

LLSV

COIL

SIGHT

GLASS

FILTER

DRIER

SUCTION LINE

ACCUMULATOR

38AUZ*07

3

/

8

200RB5T3M

AMG/24V

AMI-1TT3

P502-8304S*

S-7063S*

38AUZ*08

3

/

8

200RB5T3M

AMG/24V

AMI-1TT3

P502-8304S*

S-7063S*

1

/

2

200RB5T4M

AMG/24V

AMI-1TT4

P502-8304S

S-7063S*

38AUZ*12

1

/

2

200RB6T4M

AMG/24V

AMI-1TT4

P502-8307S*

S-7063

38AUZ*14

5

/

8

200RB6T5M

AMG/24V

AMI-1TT5

P502-8307S*

S-7063

*Bushings required.

LEGEND

TXV — Thermostatic Expansion Valve

Factory

High-Flow

Access Port

Service Valve

with Stem Cap

Field Service

Access Port

(Schrader core)

Sweat

Connection

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury,

death and/or equipment damage.

Puron® (R-410A) refrigerant systems operate at higher

pressures than standard R-22 systems. Do not use R-22

service equipment or components on Puron refrigerant

equipment.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit cabinet

must have an uninterrupted, unbroken electrical ground to

minimize the possibility of personal injury if an electrical

fault should occur. This ground may consist of electrical

wire connected to unit ground lug in control compartment,

or conduit approved for electrical ground when installed in

accordance with NEC (National Electrical Code); ANSI/

NFPA 70, latest edition (in Canada, Canadian Electrical

Code CSA [Canadian Standards Association] C22.1), and

local electrical codes.