Carrier 38AUZ User Manual

Page 15

15

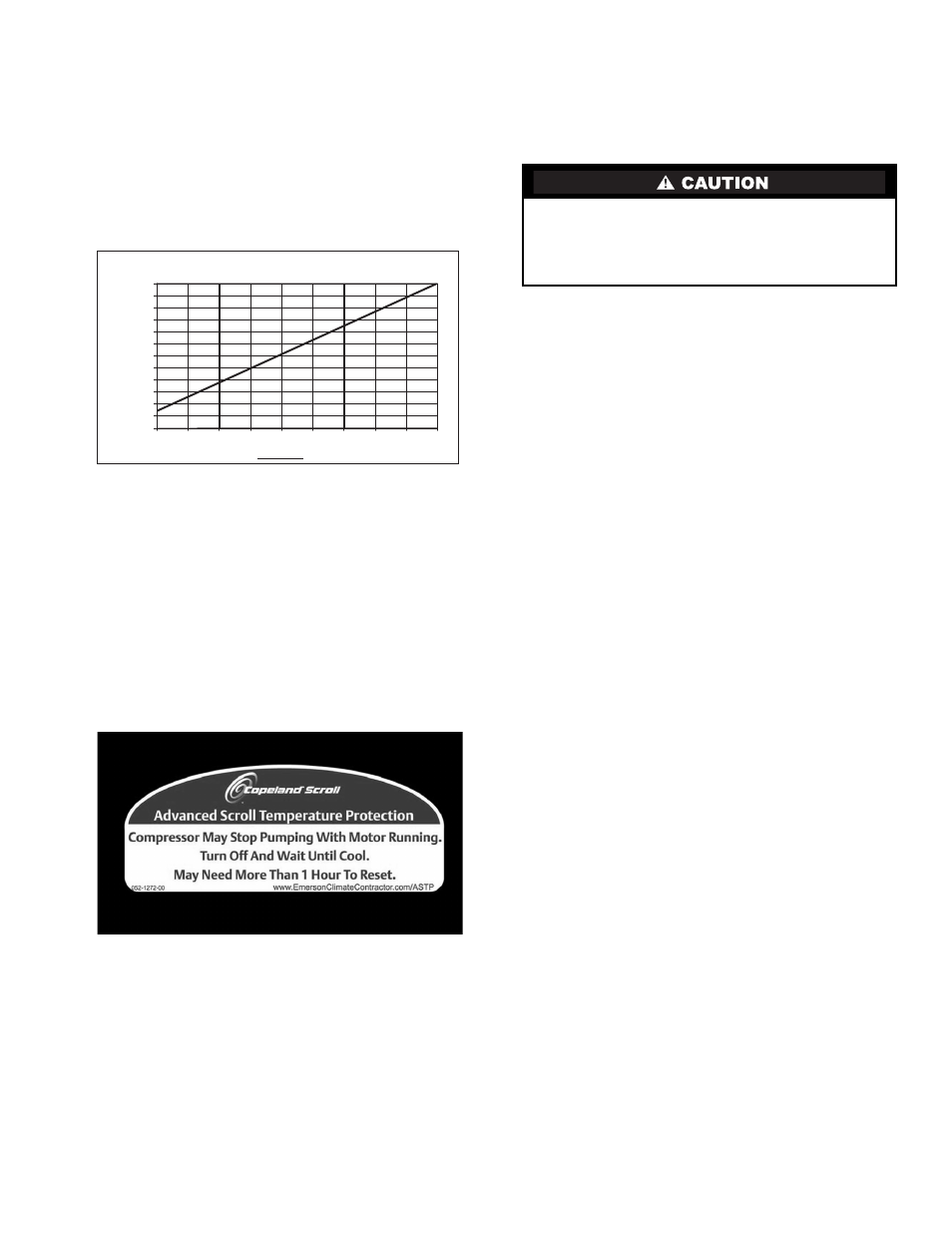

ADVANCED SCROLL TEMPERATURE PROTECTION

(ASTP) — Advanced Scroll Temperature Protection (ASTP)

is a form of internal discharge temperature protection, used in

38AUZ*12 and 38AUZ*14 units, that unloads the scroll com-

pressor when the internal temperature reaches approximately

300°F. At this temperature, an internal bi-metal disk valve

opens and causes the scroll elements to separate, which stops

compression. Suction and discharge pressures balance while

the motor continues to run. The longer the compressor runs un-

loaded, the longer it must cool before the bi-metal disk resets.

See Fig. 14.

Fig. 14 — Recommended Minimum Cool-Down Time

After Compressor is Stopped

To manually reset ASTP, the compressor should be stopped

and allowed to cool. If the compressor is not stopped, the motor

will run until the motor protector trips, which occurs up to

90 minutes later. Advanced Scroll Temperature Protection will

reset automatically before the motor protector resets, which

may take up to 2 hours. A label located above the terminal box

identifies Copeland Scroll compressor models (ZP103 and

ZP137) that contain this technology. See Fig. 15.

Fig. 15 — Advanced Scroll Temperature

Protection Label

START UNIT — The field disconnect is closed, the indoor

fan circuit breaker is closed, and the space thermostat is set

above ambient so that there is no demand for cooling. Only the

crankcase heater will be energized.

Reset the space thermostat below ambient so that a call for

cooling is ensured.

ADJUST REFRIGERANT CHARGE — The unit must be

charged in Cooling mode only. Refer to Cooling Charging

Charts, Fig. 16 through Fig. 19. For applications with line

lengths greater than 100 ft, contact Carrier representative. Vary

refrigerant until the conditions of the chart are met. Note that

the charging charts are different from the type normally used.

The charts are based on charging the units to the correct sub-

cooling for the various operating conditions. Accurate pressure

gage and temperature sensing device are required. Connect the

pressure gage to the service port on the liquid line service

valve. Mount the temperature sensing device on the liquid line

close to the liquid line service valve, and insulate it so that out-

door ambient temperature does not affect the reading. Indoor

airflow must be within the unit’s normal operating range. Oper-

ate the unit for a minimum of 15 minutes. Ensure that pressure

and temperature readings have stabilized. Plot the liquid pres-

sure and temperature on chart and add or reduce the charge to

meet the curve. Adjust the charge to conform with the charging

chart, using the liquid pressure and temperature to read the

chart.

FINAL CHECKS — Ensure that all safety controls are

operating, control panel covers are on, and the service panels

are in place.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

10

20

30

40

50

60

70

80

90

Compressor Unloaded Run Time (Minutes)

R

ec

om

m

ende

d C

ool

ing

Ti

m

e

(Mi

nu

tes

)

*Times are approximate.

NOTE: Various factors, including high humidity, high ambient tem-

perature, and the presence of a sound blanket will increase cool-

down times.

Never charge liquid into the low-pressure side of system.

Do not overcharge. During charging or removal of refriger-

ant, be sure indoor-fan system is operating. Ensure both

outdoor fan motors are running; bypass any Motormaster

function.