Carrier 38AUZ User Manual

Page 22

22

NOVATION™ Coil Cleaning and Maintenance —

To clean the NOVATION condenser coil, chemicals are NOT

to be used; only water is approved as the cleaning solution.

Only clean potable water is authorized for cleaning

NOVATION condensers.

Clean the coil as follows:

1. Turn off unit power.

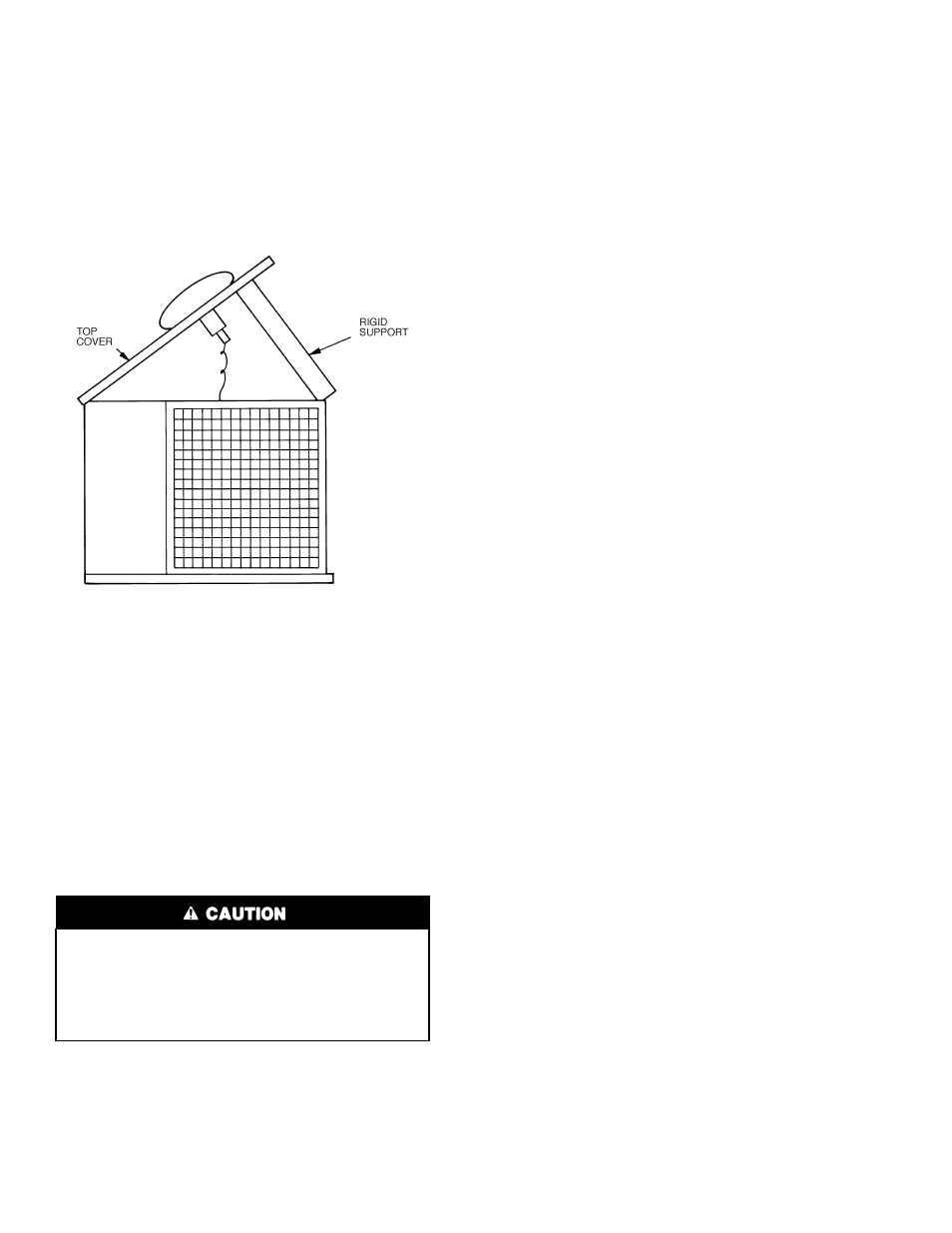

2. Remove screws holding rear corner posts and top cover

in place. Pivot top cover up 12 to 18 in. (305 to 457 mm)

and support with a rigid support. See Fig. 21.

Fig. 21 — Pivot and Support Top Cover

3. Carefully remove any foreign objects or debris attached

to the coil face or trapped within the mounting frame and

brackets.

4. Using a high pressure water sprayer, purge any soap or

industrial cleaners from hose and/or dilution tank prior to

wetting the coil.Clean condenser face by spraying the coil

core steadily and uniformly from top to bottom, directing

the spray straight into or toward the coil face. Do not

exceed 900 psig or a 45 degree angle; nozzle must be at

least 12 in. (30 cm) from the coil face. Reduce pressure

and use caution to prevent damage to air centers (fins).

Do not fracture the braze between air centers and

refrigerant tubes. Allow water to drain from the coil core

and check for refrigerant leaks prior to start−up.

5. Replace top cover and rear corner posts.

Repairing NOVATION Condenser Tube Leaks

RCD offers service repair kit Part Number 50TJ660007 for

repairing tube leaks in the NOVATION coil crosstubes. This kit

includes approved braze materials (aluminum fluxcore braze

rods), a heat shield, a stainless steel brush, replacement fin

segments, adhesive for replacing fin segments, and instructions

specific to the NOVATION aluminum coil. See EPIC for

instruction sheet 99TA526379.

The repair procedure requires the use of MAPP gas and torch

(must be supplied by servicer) instead of conventional

oxyacetylene fuel and torch. While the flame temperature for

MAPP is lower than that of oxyacetylene (and thus provides

more flexibility when working on aluminum), the flame

temperature is still higher than the melting temperature of

aluminum, so user caution is required. Follow instructions

carefully. Use the heat shield.

Replacing NOVATION Condenser Coil

The service replacement coil is preformed and is equipped with

transition joints with copper stub tubes. When brazing the

connection joints to the unit tubing, use a wet cloth around the

aluminum tube at the transition joint. Avoid applying torch

flame directly onto the aluminum tubing.

Field Refrigerant Access Ports

Field service access to refrigerant pressures is through the

access ports located at the service valves (see Fig. 6). These

ports are ¼-in SAE Flare couplings with Schrader check valves

and service caps. Use these ports to admit nitrogen to the field

tubing during brazing, to evacuate the tubing and evaporator

coil, to admit initial refrigerant charge into the low-side of the

system and when checking and adjusting the system refrigerant

charge. When service activities are completed, ensure the

service caps are in place and secure; check for leaks. If the

Schrader check valve must be removed and re-installed, tighten

to 2-3 in-lbs (23-34 N-cm).

Factory High-Flow Access Ports

There are two additional access ports in the system - on the

suction tube between the compressor and the suction service

valve and on the liquid tube near the liquid service valve (see

Fig. 6). These are brass fittings with black plastic caps. The

hose connection fittings are standard ¼-in SAE Male Flare

couplings.

The brass fittings are two-piece High Flow valves, with a

receptacle base brazed to the tubing and an integral spring-

closed check valve core screwed into the base. (See Fig. 22.)

This check valve is permanently assembled into this core body

and cannot be serviced separately; replace the entire core body

if necessary. Service tools are available from RCD that allow

the replacement of the check valve core without having to

recover the entire system refrigerant charge. Apply compressor

refrigerant oil to the check valve core's bottom o-ring. Install

the fitting body with 96 ±-10 in-lbs (1085 ±23 N-cm) of

torque; do not overtighten.

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury

or equipment damage.

Chemical cleaning should NOT be used on the aluminum

microchannel condenser. Damage to the coil may occur.

Only approved cleaning is recommended.