Maintenance, Lubrication, Hydrostatic transmission – Bolens 140-990A User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. The engine should be run with the throttle

control in the “FAST” position to obtain the

maximum efficiency. The sound you may hear

when you accelerate is the normal operating

sound of the hydrostatic transmission. The

faster you push the control lever forward or

backward, the louder the sound.

3. Release the brake and move the control lever

into either the forward (F) or reverse (R) posi

tion.

4. The brake pedal is used for emergency stop

ping only. Normal stopping is done by using

the control lever. When the brake pedal is

depressed the control lever will return close

to the neutral position so the tractor brake will

stop the tractor, however, the tractor may

creep either forward or backward when the

brake pedal is released.

Maintenance and adjustments for the engine are

covered in the Engine Operating and Maintenance

Instructions manual.

MAINTENANCE

Lubrication

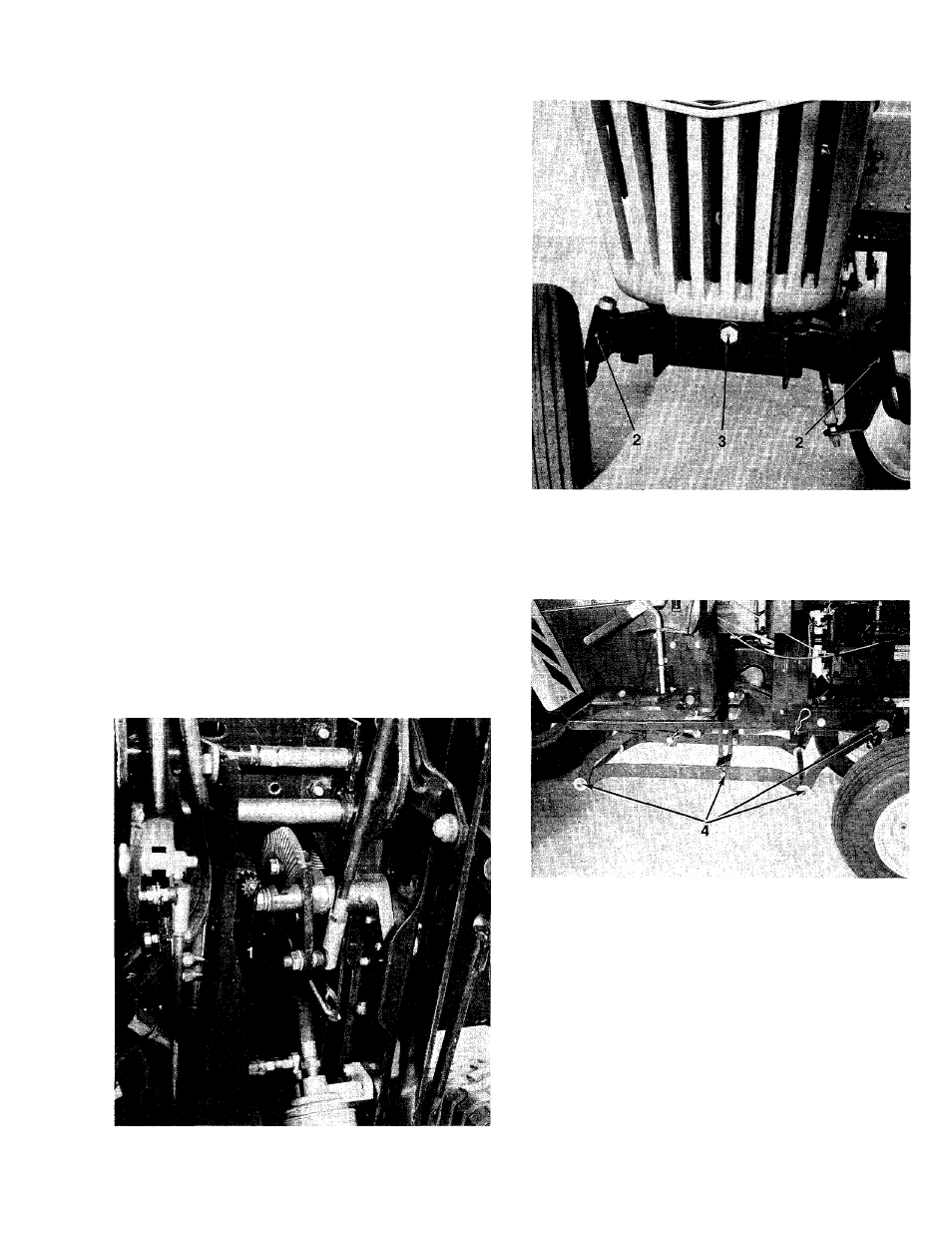

Item numbers 1 through 4 must be lubricated once

a year with multi-purpose automotive grease.

1. Steering Gear—(See figure 20.)

2. King Pin—(See figure 21.)

3. Pivot Bolt—(See figure 21.)

4. Deck Linkage—Oil with SAE 30 oil on all pivot

points once a season. (See figure 22.)

FIGURE 21.

FIGURE 20.

FIGURE 22.

5. Hydrostatic Transmission

(See figure 23.) The dipstick for the

hydrostatic transmission is located behind

the seat. This dipstick checks the oil level in

the hydrostatic transmission, transaxle and

hydraulic lift system.

The oil level should be maintained to the

FULL mark on the dipstick. Check the oil level

every 8 hours of operation.

Use 20 weight oil with a zinc additive package

of .07% minimum. The following list of oils

meet these specifications:

13