Corrosion protection, Freezing weather protection, Vii. start-up and adjustments – Bryant 479 D User Manual

Page 6: Pilot adjustment, Table iii, Approved antifreeze types

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

11. Remove chiller tank lids, and add contents of

chilled water package (one package to each chilled

water tank is sufficient).

12. Replace both chiller tank lids and reconnect con

denser fan motor leads in the chiller control boxes.

13. Turn on water pumps. Pumps should operate a

minimum of 10 minutes to dissolve all chilled water

additive when chilled water additive is used.

14. Replace access panels and tirrn on manual gas

valves to both chillers. Cooling section is now ready to

operate.

Corrosion Protection

The metallic components of the chilled water system

must be protected from corrosion by the addition of

an inhibitor to the chilled water circuit of each chiller.

Two packages of chilled water additive are furnishèd

with the unit. The contents of one package of Chilled

Water Additive P/N 62875D1 must be added to the

chilled water circuit of each chiller when water only

or when water and methanol antifreeze are used in

the chilled water system.

Do

not

add any chilled water additive to the system

when Ucar-17 is used for freeze protection. Ucar-17

contains sufficient inhibitor when used in the recom

mended concentrations as shown in Table III.

Freezing Weather Protection

Freeze protection is only required when the chilled

water coil is subjected to freezing temperatures or

when the unit is to operate under freezing conditions.

The cooling section is equipped with galvanized

chillers. Ucar-17 is the only permanent (glycol-base)

antifreeze approved for use in the chilled water

system. When Ucar-17 is used for freeze protection,

the minimum concentration must be 33% by volume.

Table III gives the types of antifreeze, percent of an

tifreeze concentration, and amount of antifreeze to

use in each chiller of the 180 and 240-479 at various

outdoor temperatures.

VII. START-UP AND ADJUSTMENTS

Important: Before starting the heating or cooling sec

tion, make certain all electrical connections have been

made and the gas piping has been connected, purged

and leak tested.

CAUTION; Recheck all factory and field connections,

making sure they are tight.

Pilot Adjustment

Remove necessary access panels from furnace and

chillers.

Light pilots according to instructions on furnace and

chillers.

For Natural Gas. Flame should be of sufficient length

to provide good impingement on the monometal of the

Bryant pilot. The flame should extend upward bet

ween the carryover ports of the two adjacent burners.

For Propane Gas. Flame should surround tip of the

thermocouple element of the pilot and extend down

ward to include 3/8” to 1/2” of the thermocouple. The

flame must not come in contact with any other part of

the thermocuple or its lead wire. The flame lies under

the carryover ports of the burners and merges with the

carryover flames.

The pilot flame can be adjusted if it does not have the

appearance described above. The pilot adjusting

screw for natural and propane units (chillers and fur

nace) is located under a screw cap in the handle of the

manual pilot shut off valve. Adjust as follows;

1. Remove the screw cap to expose the adjusting

screw, then turn pilot flame to full on position.

2. Turn the adjusting screw until the flame has the

desired appearance.

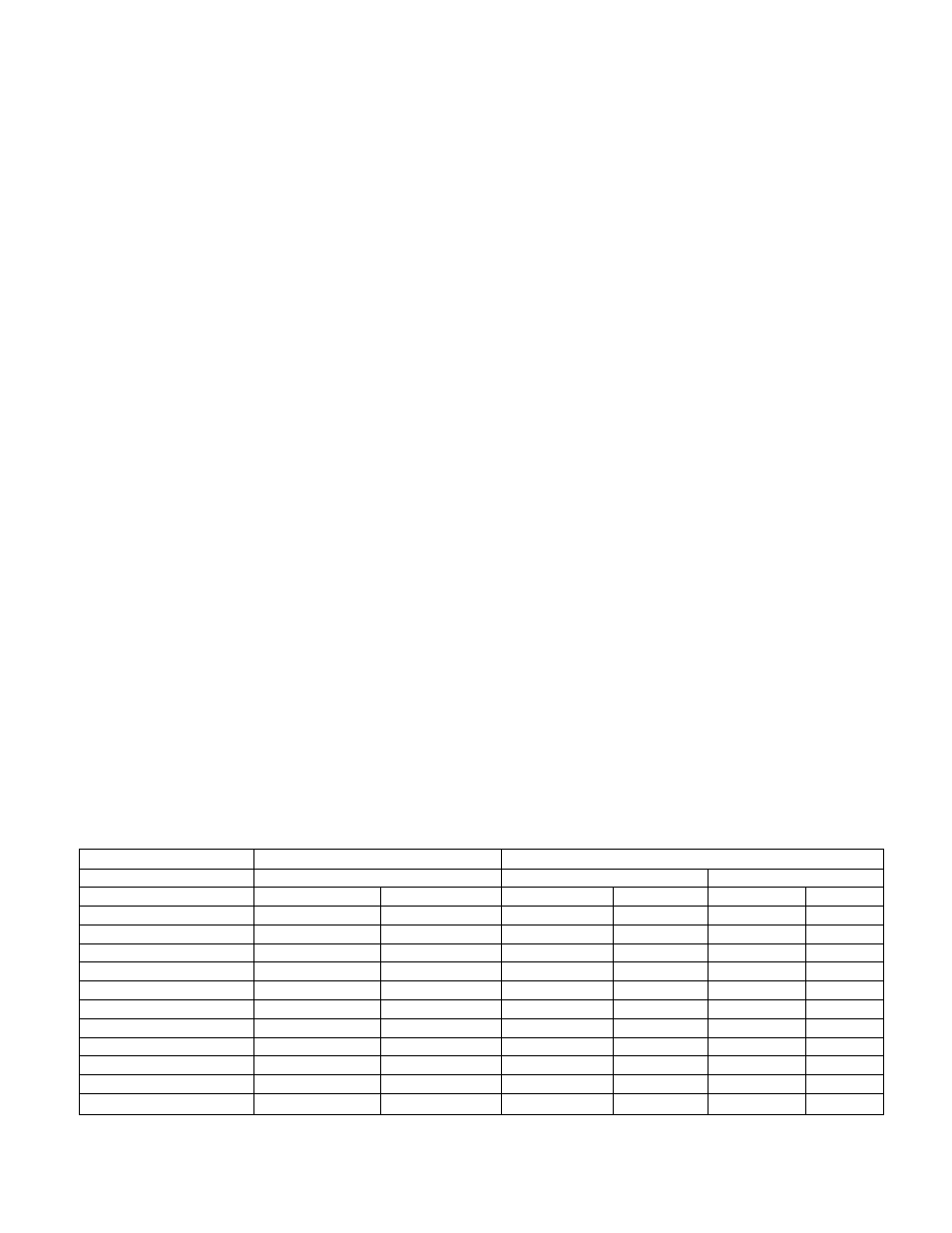

TABLE III

APPROVED ANTIFREEZE TYPES

Amount Required (Galions)

Lowest Outdoor

Percent of Concentration

180-479 (Each Chiiier)

240-479 (Each Chiller)

Temperature (°F)

^Methanol

**Ucar-17

Methanol

Ucar-17

Methanol

Ucar-17

20

20

33

2-1/2

4-1/4

2-3/4

4-1/2

15

20

33

2-1/2

4-1/4

2-3/4

4-1/2

10

22

33

2-3/4

4-1/4

3-1/4

4-1/2

5

26

33

3-1/4

4-1/4

3-3/4

4-1/2

0

29

33

3-3/4

4-1/4

4

4-1/2

-5

32

36

4

4-1/2

4-1/2

5

'10

34

39

4-1/4

4-3/4

4-3/4

5-1/4

-15

36

42

4-1/2

5-1/4

5

5-3/4

-20

38

45

4-3/4

5-1/2

5-1/4

6-1/4

-25

43

47

5-1/4

5-3/4

6

6-1/2

-30

44

49

5-1/2

6

6

6-3/4

^Chilled water Additive (Borax and Chromate) P/N 62875D1 must also be used. Refer

to “Corrosion Protection” on page 6.

**No chilled water additive required. Refer to “Corrosion Protection” on page 6.

-6-