Condensate drain, Ground level installation, Clearances – Bryant 479 D User Manual

Page 3: Ii. installing vent caps, Iii. duct connections, Iv. gas connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The mounting base should comply with local codes

and be made of noncombustible material. The recom

mended types of mounting bases for all installations

are:

a.

Precase concrete lintels.

Use three lintels run the

depth of the unit; one under the right end, one under

the left end, and one at the center of the unit.

b.

Steel beams.

Use three I-beams run the depth of

the unit; one under each end and one at the center.

c.

Concrete Slab.

A minimum thickness of four inches

is required.

Rooftop Installation

When installing the 479 on a roof or other com

bustible material, use noncombustible supports and

allow a 6 inch clearance beneath the unit’s subbase

for proper air circulation. Be sure the roof construc

tion will support the weight of the equipment. Locate

the unit above a load-bearing wall whenever possible.

Condensate Drain

The 479 is furnished with a 3/4 inch FPT drain con

nection. If the installation requires draining the con

densate away from the roof of the building, connect

tubing, pipe, hose or trough and pitch downward one

inch for every ten feet of horizontal run.

Ground Level Installation

The 479 should be placed on a concrete slab at least 4

inches thick. Level the unit on the slab and be sure

there is adequate drainage away from its base.

Clearances

The minimum clearances are 6 inches from the duct

side and 24 inches from all other sides.

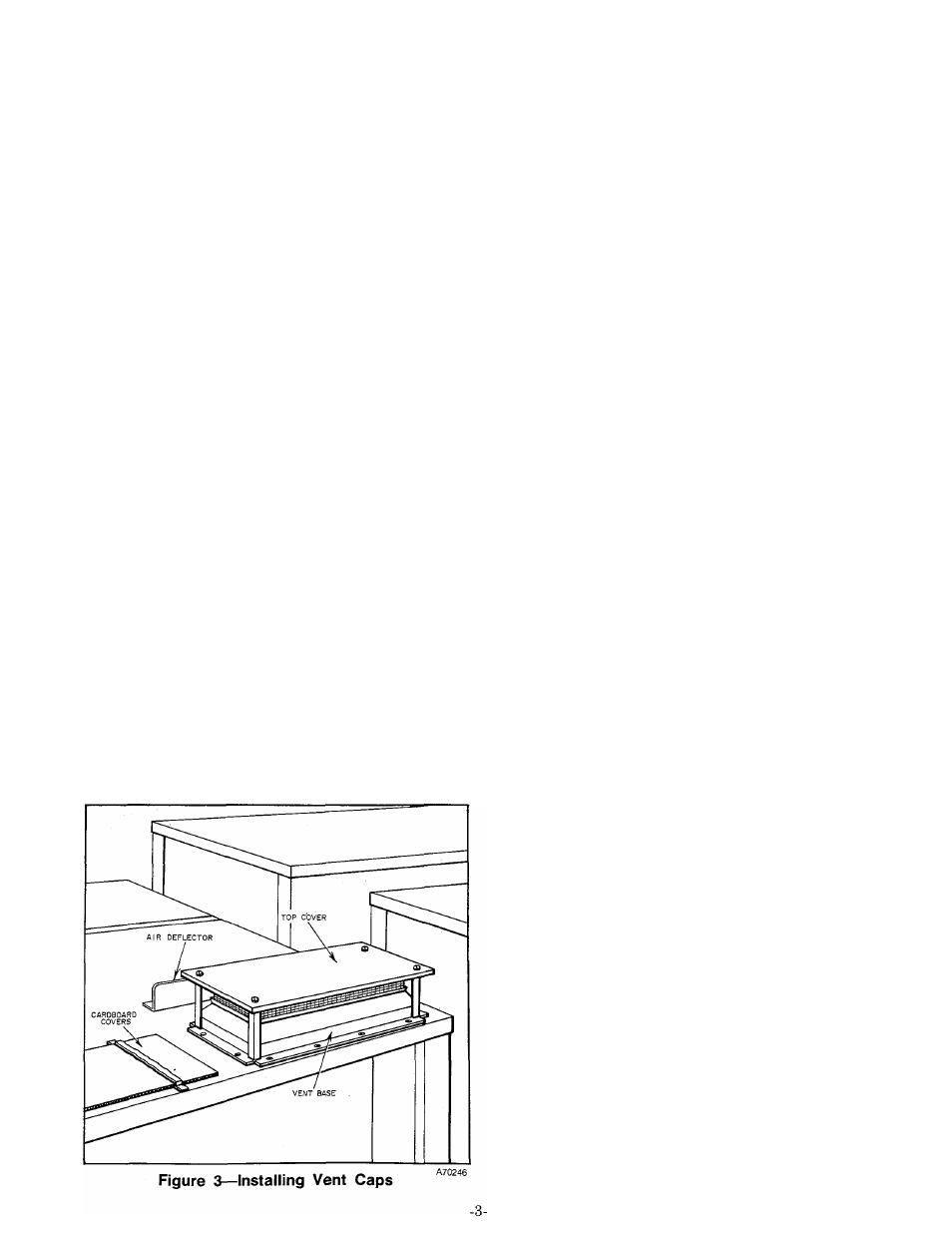

II. INSTALLING VENT CAPS

The vent cap assemblies are packaged and shipped in

the heating section coil compartment. Install the vent

cap assemblies as follows. See Figure 3.

Mounting Bases

1. Remove the cover on each of the vents on the roof

of the unit.

2. Use the FAJ5606B screws supplied with the assem

blies to fasten the base section of the vent cap assem

bly.

3. Remove the three self-tapping screws in the top

cover, located approximately 7 inches behind each

vent cap. Attach one of the air deflectors in this

location for each vent cap, using the screws removed.

III. DUCT CONNECTIONS

Before attaching the ducting to the unit, remove the

sheet metal panel that is used to protect the outlet

and return openings. The ductwork may be screwed or

bolted to the unit flange with suitable gaskets to in

sure a weathertight seal. Be sure the sheet metal

overlaps the flange on the unit.

CAUTION: Take care not to puncture the evaporator

coil when drilling the duct flange.

All duct work external of the structure must be

properly insulated and water-proofed.

All openings in the structure must be properly flashed

and vibration isolated in accordance with local codes

and good building practices. Supply and return duct

work should be provided with an approved vibration

eliminator. The vibration eliminator must be located

within the structure.

IV. GAS CONNECTIONS

The gas supply pipe for the Model 479 should be a

direct line from the gas meter or propane supply tank.

The gas supply pipe should terminate at the unit with

a tee.

The size of the gas pipe used depends upon the length

of run and allowable pressure loss established by the

utility. Never use pipe smaller than the gas connection

to the unit manifold.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe. It is best to

grade all pipe 1/4 inch in every 15 feet to prevent

traps. All horizontal runs should grade up to risers.

2. A drip leg must be provided at any point in the line

of pipe where condensate may collect. Such drip leg or

drip legs shall be installed in locations readily ac

cessible to permit cleaning or emptying. The drip legs

should not be located where they are subject to

freezing. See Figure 4. Check local codes for size and

capacity of drip legs.

3. Three manual shutoff valves should be installed;

one valve between the gas supply pipe and heating

section, and one between each chiller and the gas sup

ply pipe.

4. A ground joint union should be installed between

the individual gas controls manifold and each manual

shutoff valve.