Vi. chilled water system, Charging the system with water – Bryant 479 D User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

VI. CHILLED WATER SYSTEM

The cooling section of Model 180-479 is comprised of

two 90,000 BTUH chillers and a 180,000 BTUH

cooling coil which is divided into two separate 90,000

BTUH sections (top and bottom). The bottom section

of the chilled water coil is supplied chilled water by

one chiller (1st stage cooling) while the top section of

the chilled water coil is supplied chilled water by the

other chiller (2nd stage cooling). The chilled water

circuit of each chiller is independent of the other;

therefore, each chiller must be charged with water

before the cooling section can be operated.

The design of Model 240-479 is basically the same as

that of Model 180-479 except the 240-479 utilizes two

120,000 BTUH chillers and a 240,000 BTUH cooling

coil which is divided into two separate 120,000 BTUH

sections. Each chiller of the Model 240-479 must also

be charged with water since the chilled water circuit

of each chiller is independent of the other.

CAUTION: The water seals will be damaged if the

pumps are operated without water in the system.

Freezing conditions will not damage the pumps;

however, do not operate the pumps when the chillers

or chilled water lines are frozen.

Charging the System with Water

Charge the chilled water system with water as

follows:

1. Turn off manual gas valves to both chillers and

turn off electrical power at disconnect switch.

2. Remove access panel from both of the chillers at'

the chiller tank end. Remove chilled water tank lids.

3. Fill both chiller tanks with water having less than

100 ppm chlorides until distributor pans are covered,

or add 12.2 gallons to each chiller of Model 180-479

or 13.6 gallons to each chiller of Model 240-479.

NOTE: If the local tap water has more than 100 ppm

chlorides, charge the chilled water system with

distilled or deionized water. Check the local water

company and/or county agricultural agent for analysis

of tap water being used in your area.

CAUTION: Never use home soft water, water sof

tening additives, water cleaning compounds, coloring

additives, acidizing materials, stop leak additives, or

other commercial water additives in the chilled water

system.

WARNING: To prevent personal injury, disconnect

condenser fan motor lead in the control box of each

chiller at this time.

4. Replace both chiller tank lids, then start water

pumps.

If water of either chiller does not circulate when the

pumps are started, air may be trapped in the system.

Most chillers are equipped with a Gorman-Rupp

water pump (plastic). On these chillers, it is necessary

to disconnect the chilled water line at the chiller tank

to bleed the air. Operate water pumps until water ap

pears at the disconnected water line, then reconnect

water line to chiller tank.

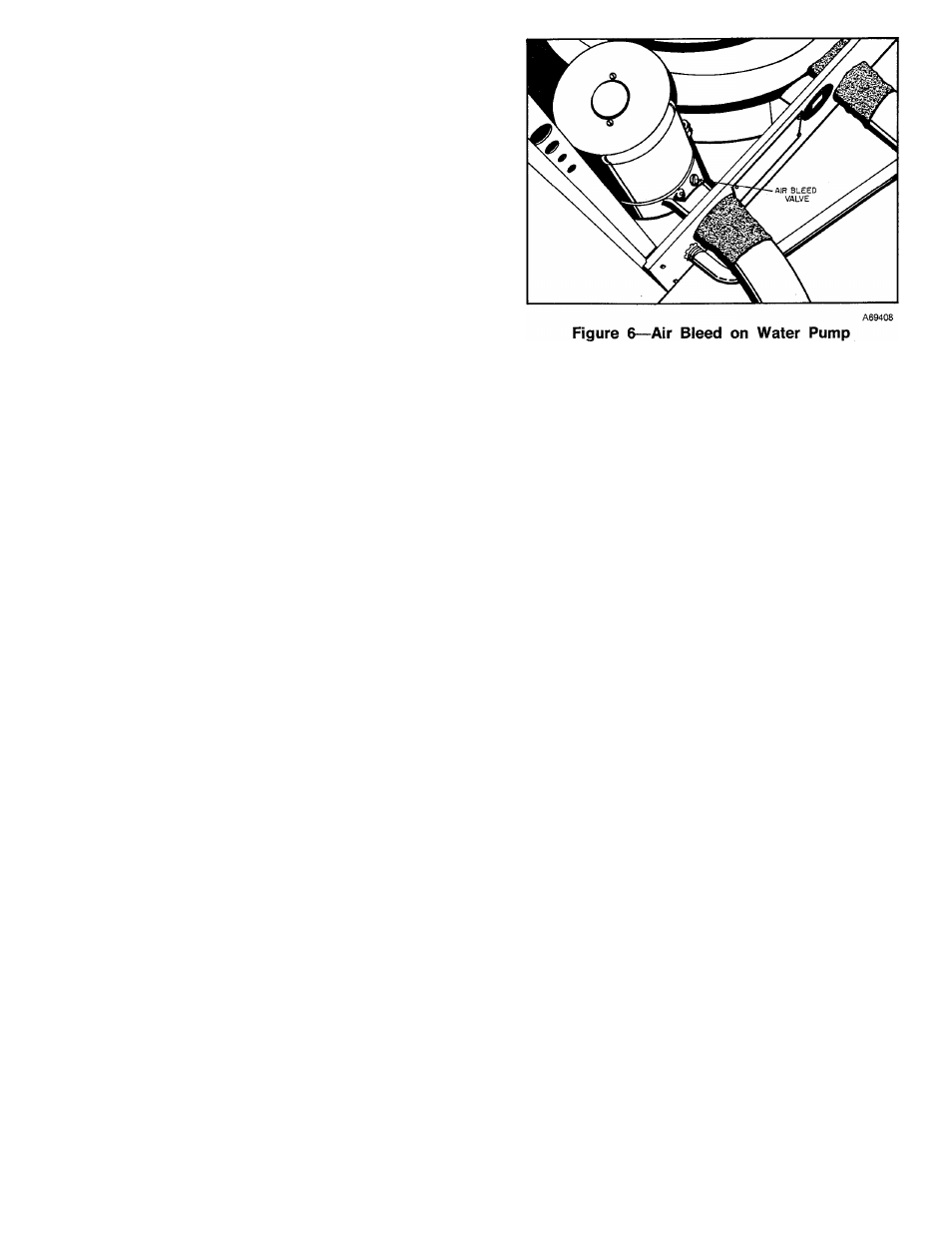

If the chiller with the trapped air is equipped with a

Wayne water pump (metal), it is not necessary to

disconnect the water line to bleed the trapped air.

Bleed the air from the pump through the 1/4-inch slot

ted head valve located on top of the pump discharge.

See Figure 6. Open valve with a screwdriver. Close

valve when a steady stream of water appears.

5. Leak test the chilled water system.

6. Remove operating level drain plug (located on side

of tank) from both chilled water tanks and continue

to operate pumps until water stops flowing from drain

openings.

NOTE: With the pumps running, the water level is

correct for each chiller when water stops flowing from

its drain opening.

7. Replace operating level drain plugs, then turn off

pumps.

8. Refer to “Freezing Weather Protection” on page

6. If freeze protection is required, decide on which

type of antifreeze to use.

The procedure for adding Ucar-17 is given in Step 9.

The procedure for adding methanol antifreeze is given

in Step 10. If antifreeze is not required, disregard

Steps 9 and 10.

9. Adding Ucar-17 Antifreeze - Refer to Table III.

Drain out amount of water from

each

chiller tank,

equal to amount of antifreeze to be added. Add

required amount of Ucar-17 to each chiller tank.

Recheck operating water level and correct. Do

not

use

any chilled water additive when using Ucar-17 in the

recommended concentration. Omit Steps 10 and 11.

10. Adding Methanol Antifreeze - Refer to Table III.

Drain out amount of water from

each

chiller, equal to

amount of antifreeze to be added. Add required

amount of methanol antifreeze. Add the contents of

the chilled water additive package as described in

Step 11.

-

5

-