Ivvarning, Carburetor adjustments (see figure 22), Important – Bolens 122-336-120 User Manual

Page 12: Maintenance, Cutting blade, I warning i, Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

i v V A R N I N G {

If any adjustments are made to the

engine while the engine is running

(e.g.

carburetor),

disengage

all

clutches and blades. Keep clear of

all

moving

parts.

Be

careful

of

heated surfaces and muffler.

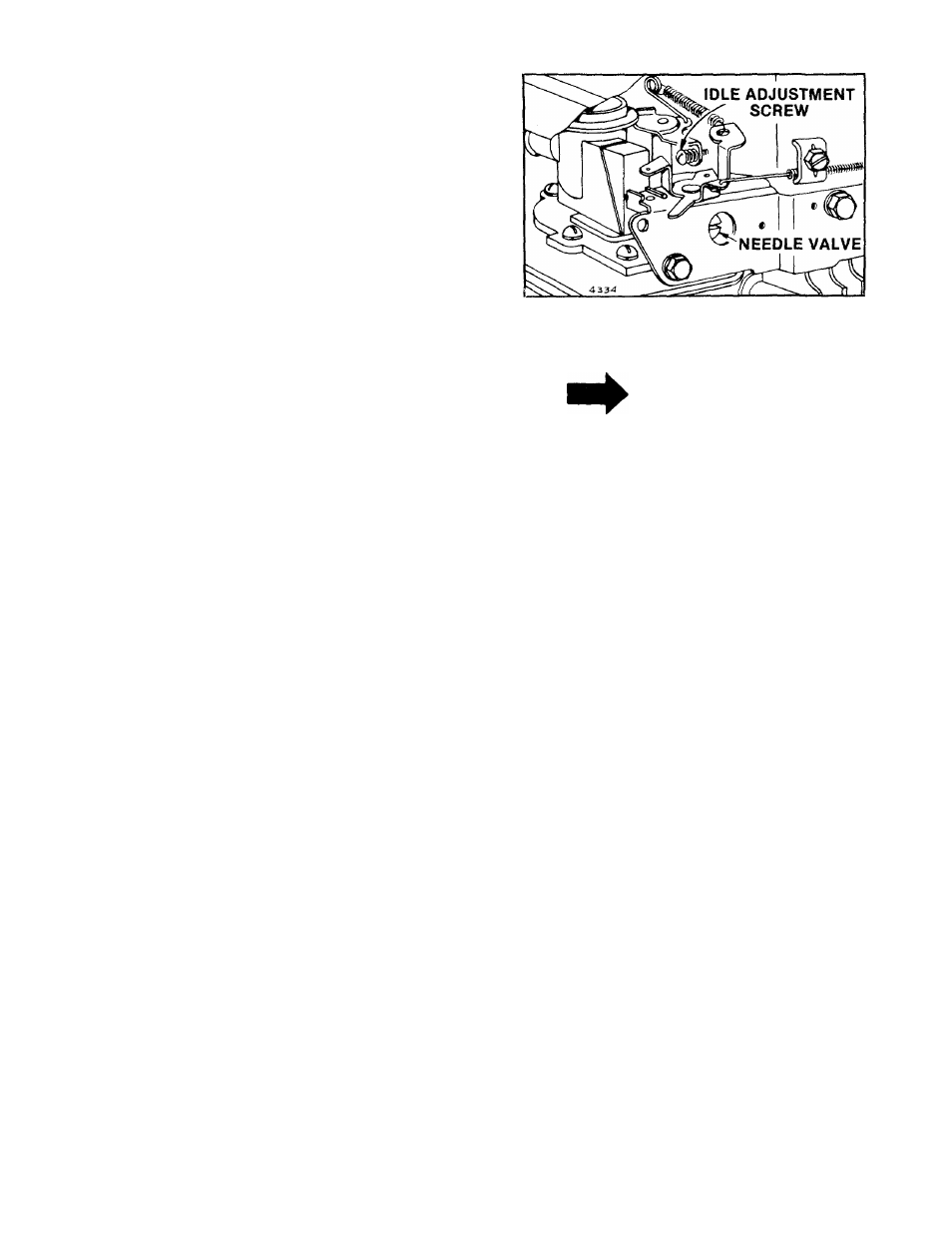

CARBURETOR ADJUSTMENTS (See Figure 22)

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

All carburetor adjustments should be made with

the air cleaner on engine. Air cleaner mounting

screw must be in carburetor when engine is run.

Best adjustment is made with a fuel tank half full

of gasoline.

To Adjust Carburetor:

1. Start engine and run long enough to warm it to

operating temperature.

If engine is out of adjustment so that it will

not start, close the needle valve by turning it

clockwise. Then open needle valve 1-1/2 turns

counterclockwise.

2. Move engine control to run engine at

normal

operating speed.

a. Turn needle valve in clockwise until engine

starts to lose speed (lean mixture).

b. Then slowly turn needle valve out counter

clockwise

past

the

point

of

smoothest

operation until engine just begins to run

unevenly (rich mixture).

c. Turn needle valve back in clockwise very

slowly till engine runs evenly.

d.

Final

adjustment

of the needle valve

should be slightly to the rich side (turn

counterclockwise) of the mid-point.

3. Move engine control to SLOW. Turn idle ad

justing screw until a fast idle is obtained (1750

R.P.M.).

4.

To check adjustment, move engine control

from SLOW to FAST speed. Engine should ac

celerate smoothly. If engine tends to stall or

die out, increase idle speed or readjust car

buretor, usually to a slightly richer mixture.

FIGURE 22.

LUBRICATION

IMPORTANT

Always stop engine and disconnect

spark

plug

wire

before

cleaning,

lubricating or doing any kind of work

on lawn mower.

Wheels—Front

and rear wheel

bearings are

of

self-lubricating Fortiflex. They require no lubrica

tion. However, if the wheels are removed for any

reason, lubricate the surface of the axle bolt and

the inner surface of the wheel with light oil. A 4 oz.

plastic bottle of light oil lubricant is available.

Order part number 737-0170. Engine oil may also

be used.

Engine—Follow engine manual for lubrication in

structions.

Throttle—Periodically

lubricate

throttle

control

lever and throttle wire assembly with a few drops

of light oil for ease of operation.

Discharge Chute Door Mechanism—The torsion

spring

and

pivot

point

should

be

lubricated

periodically with light oil to prevent any rust or

binding. Doors must work freely.

Bronze

Bearings—Periodically

lubricate

all

bronze bearings with a few drops of light oil to

minimize friction.

MAINTENANCE

CUTTING BLADE

A. Removal for Sharpening or Replacement

I WARNING I

Be sure to disconnect and ground

the spark plug wire before working

on

the

cutting

blade

to

prevent

accidental engine starting.

12