Bryant 364AAN User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 3

UTC TECH PUB

F A X N o . 3 1 7 2 4 0 5 6 6 2

P .

(5>

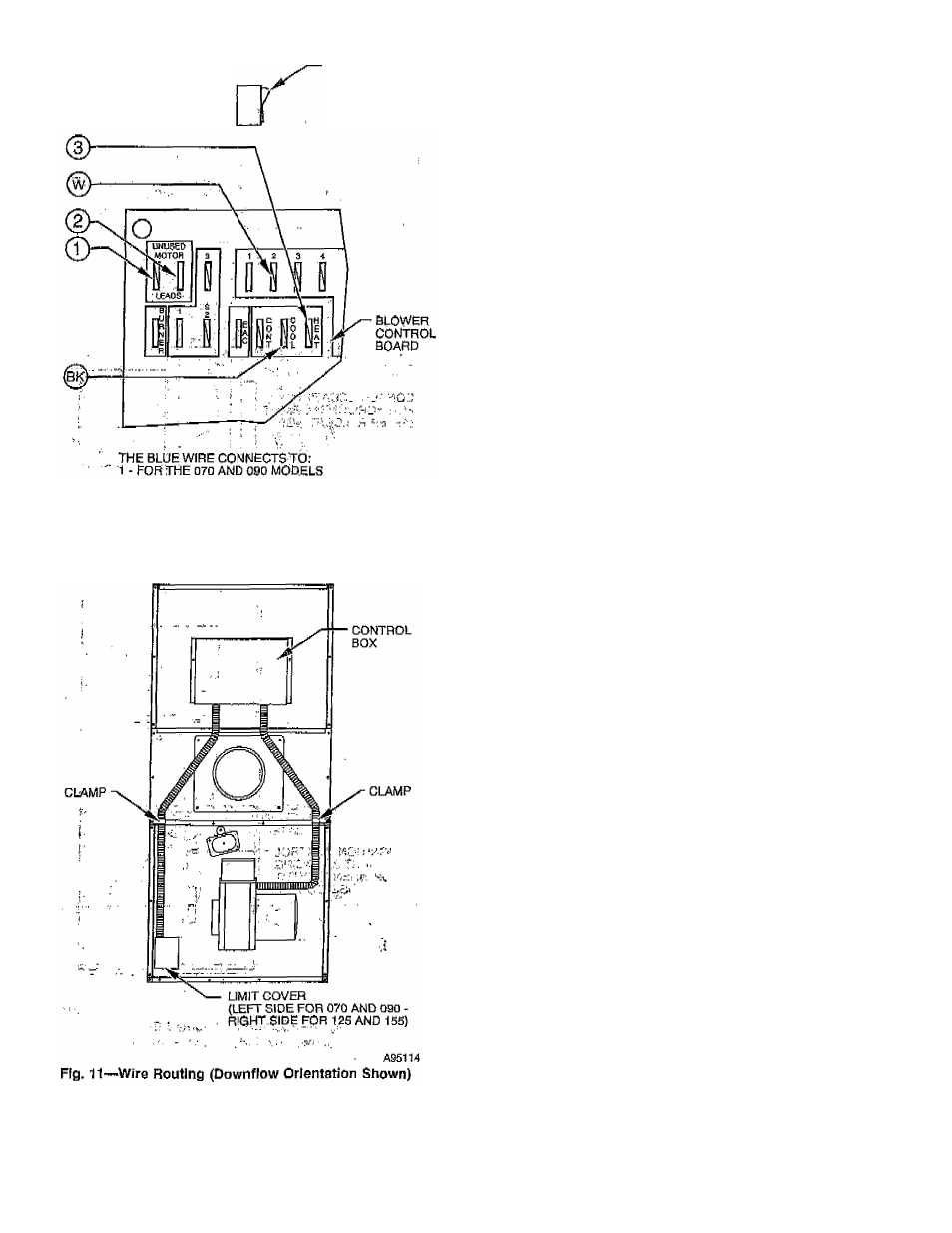

CONSTANT BLOWER

ROCKER SWITCH

2 - FOR STHE..155.MODEL OR

3 - F O R THE 125 MODEL

R = RED

BK = BLACK

\N =

WHITE

Fig. lo-T-Blowor Control Board

АЙЙИЙ

A

WARNING:

Do not

u$c

this furnace as a construction

heater. Use of this furnace as a construction heater

exposes furnace to abnormal conditions* contaminated

combustion air* and lack of air filters. Failure to follow

this warning can lead to premature furnace failure and/or

vent failure which could result in a fire hazard and/or

bodily harm, ■

A

WARNING:

Installation of this furnace in an area where

it, will .receive .contaminated combustiq^, air .¡nust be

avoidetl. Such contamination would include the follow

ing: ammonia, chlorine, hydrogen sulfide, halQgenated

hydrocarbons, carbon tetrachloride* cleaning solvents,

hydrochloric acid, water softening chemicals, and similar

chemicals, failure to follow this warning will lead to

premature rusting of heat exchanger and possible furnace

failure: .iand/or. Vent failure- which could result in fire

hazard and/or bodily .rharm.

:

^

OPERATIÜNAL^GHECK^

DO -NOT''START^BURMER :UNLESS BLOWER ACCESS

PANEL IS SECURED IN PLACE.

Installatigm of-furnace is novv .f;oinplete and operational ^checkout

may b&;:parforffled., ,_V,

2

■■

I.

START^UP :

V,

1. Check wiring against wiring'diagram shown in Fig. 16.

2. -Open valve on oil siipply line. '

3. Reset primary control.

4. Set thermostat above room temperature.

5. Set main ebctrical switch to ON position. Вигам should

start. ■ '

DO NOT TAMPERS WITH UNIT OR CONTROLS - CALL

YOUR SERVICE. TECHNICIAN.

II.

RECOMMENDED INSTALLATION PRACTICES AND

COMBUSTION CHECK

-

In order to obtain optimum performance from oil burner, the

following^setupiprocedurés must be followed:

' i-

,

1. A test kit (Bachafach No, 5022; kif^f equivalent to’measure

smoke, stack dfaft, over:^fire draft, COj, and:stacfc témjpera-

tures MUST be used in order/to’.ohtaiti pfopur mr band

setting. Although all. of the^aboyc measurements a^s re

quired for optimum setup and' efficiency data, the most

important:readings that.mustbe taken are smoke numbers,

■■; ■ ,ov.er-Ere (draft,- :and stackrdra^t:.

2. The'proper-smolid number' has,.b?en established by etigi-

- ■' ■ n'eeririg' ÍeSts tii b¿ -between 0 arid 'I'.' This degree of sm oke

emissions is commonly referred to as a "Trace" of smoke. It

is recommended to use a^Bacharnch^true spot smoke test set

or equivalents - - '

;í^■ tci'/v or-

3. In order to ensure proper dr^t,thqugh..furnace, g b^roroctric

draft regulator .(supplied, with furn4po|), must .hjs in^talícd as

close to outlet of furWee a's "poss^bl^^^^

to

function .properly, barometric ОаГОрёт'щцд!. be'mounted

with^hinge pins horizontal an^ faceipf datiíp^ veríical, (See

iristníctions included with .^эщреН) 'Lhe dr aft.,Regulator

should be adjusted after ifuniace has been firing at least

5 minutes, and stack draft should be measured and set

between-'-0:025 ¡and -ОЮЗЗ'in. wc. The draft should be

checked with, a Bacharach MZF draft gage or equivalent.

4. The dver-firf: drilft* Which is taken th/o'ugh hole provided in

observation door, is a measurement necessary to determine

if there is a blockage between oil burner and Sue outlet.

О

^ s ~