Bryant 364AAN User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 2

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

0 0 5 / 0 1 6

О

E^CTRICAL

The appliaflce must be installed in accordance with current

ANSI/NFPA 70 National Electrical Code* CSA C22.1 Canadian

Electrical Code Part 1, and/or local codes.

The control system depends on correct polarity of power supply.

Connect HOT wire (H) and NEUTRAL wire (N) as shown in Fig.

16

.

A separate line voltage supply should be used with a fused

disconnect switch or circuit breaker between main power panel

and unit. (See Fig. 16-).

A

WARNING:

The unit cabinet must have an uninter

rupted or unbroken ground to minimiie personal injury if

an electrical fault should occur. A green ground screw is

provided in control box for this connection.

Use only copper wire for 115-y supply service to unit.

When replacing any original furnace wiring* use only:^iip5“C No.

16 AWG copper wire,.

■

'

Instructions for wiring thermostat .(field supplie'd) are packed in

thermostat box. Make thermostat connections as sjiown in Fig. 16

at 24-v terminál board 0,n control box4 ;- ■

.

■ ,

When installing optional accessories to this /Appliance, follow

manufacturer’s Installation Instructions included with accessory.

Other than wiring for thermostat, wire with a minimum of lype "T"

insulation (63'’F rise) must be used for accessories- %

á

' FILTERS

A FILTER MUST BE USEÓ Wlni THIS FURNACE! ,

An external filter rack is available as optional equipment:.with this

furnace..

Л

WARNING:

Never operate,.unit without a filter or with

filter access door removed. Failure to adhere to this

warning could lead to a haaardous condition which could

lead to equipment damage and bodily harm.

I.

KEEPING FILTERS CLEAN

As a homcownerj this is your mbit important respo'jiisibility. A

dirty .filter. LteduCes ¿f^ficiency. df 'your ,System, causes erratic

perforipance of controls, and could result,in damage to^motor or

heating equipment.

. г.

1- Inspect filters at regular intervals depending upon dirt

conditions.'pof ■'hew homes, ehcplci'fiUcrs every weeliTor 4

consecutive weeks, iln all cases, inspect filters at least every

3 to 4 weeks when sysfem is inPoiistant operation. Replace

or clean filter at least at beginning of each season (heatirig

and cooling) and thereafter as ■needed.

2. If a permanent filter is used, it^can be cleaned witl); cold

water,and soap.

;;

. ,

,

Be

Sure

that filter is thoroughly dry before installing bacic' into

furnace.

-

‘

reversing

INSTRUCTIONS FOR REAR FLUE^OPTION ,

NOTE:

These steps are only for installations where it is nfecessaiy

to have flue ccumection on

Opposite

side of furnace from biimef

and controls, Jf rear flue is not required, skip to Assembly

Instructions section.

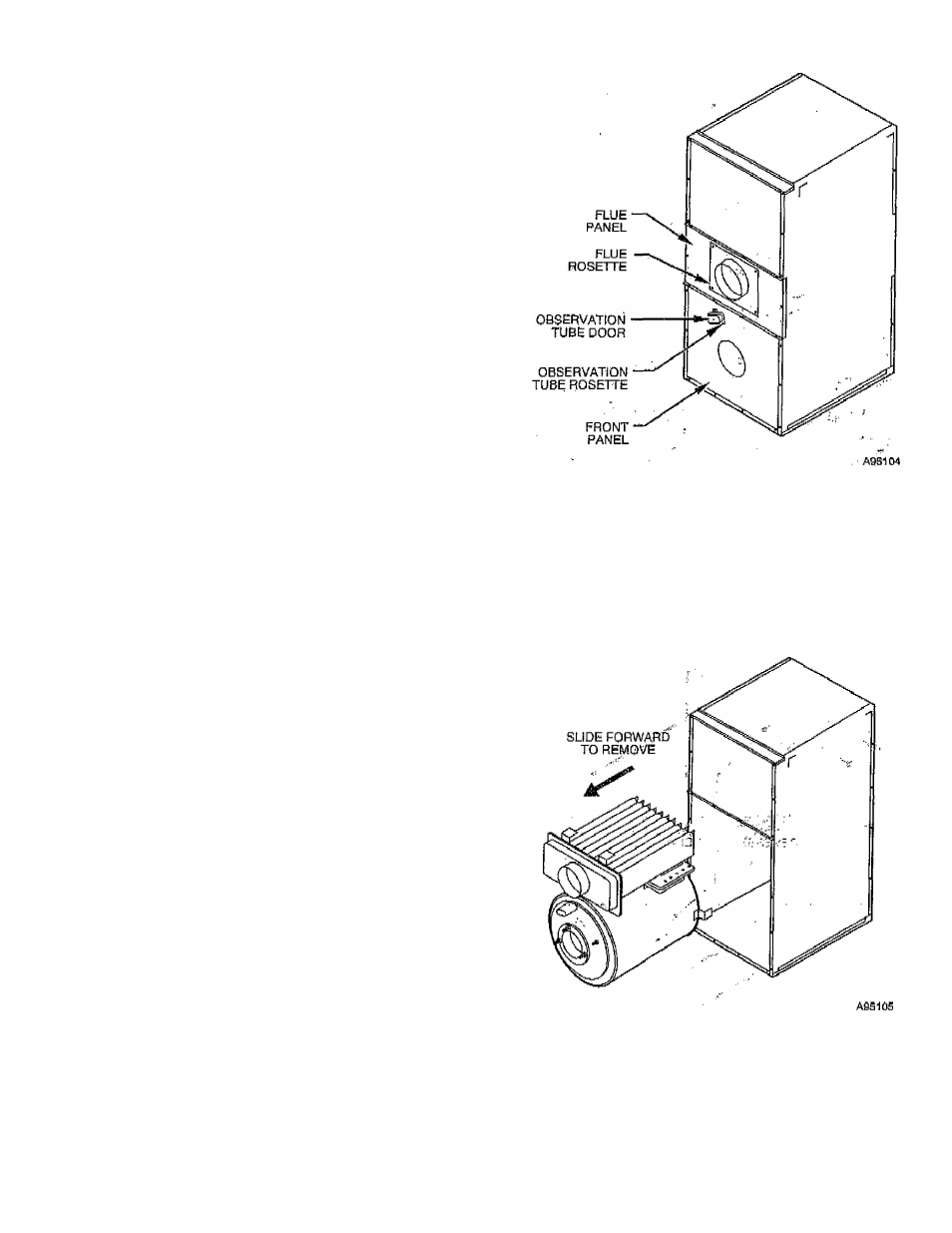

Unit should be reversed prior to installing cabinet iri position. See

Fig, 1 for cdhiponent location,

''

'

1. Remove observation tube door from front panel* taking care

not to let door spring ’’snap" hinge and pinch your fingers,

2, Remove flat rosette and gasket fram around observation

tube,-

Fig. 1"™Component Lopation..

3. Remove rosette from around fluc;oonncctof, ' . „

4. Remove front panel and flue panel from Unit,

IMPORTANT:

The heat exchanger is only secured in place by

heat exchanger ..support legs ,hopked into, brackets on blower

partition at this time. Care should be taken to adequately support

heat exchanger and prevent if from falling. Be careful not to

damage limit control.

5. Supporting heat exchanger so that it does not fail, remove

heat exchanger from cabinet by pulling it straight forward,

(See Fig. 2.)

Fig. 2—Removing Combustion Chamber and

Neat Exchanger

6. Remove cover plate/combugtion chamber assembly from

heat'exchanger drum by removing 12 parkerized screws

securing it to drum front. CAREFULLY slide combustion

chamber out of drum, taking care not to damage relatively

fragile chamber material- (See Fig, 3.)

7- Remove "blank" cover plate on rear of drum by removing

12 parkerized screws on dnim rear. Install this "blank" plate

on front (flue connector side) of drum. Ensure that gasket is

intact and all screws are secure.

- 5 ^