Bryant PAYNE 619C User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 5 — Electrical Data

INDOOR UNIT

V-PH

OPERATIONAL

VOLTAGE*

FAN

WATTS

ELECTRIC

HEATER

kW AT 240 V

MCA

MAX FUSE OR

HACR TYPE

CKT BKR AMPS

Max

Min

LRA

FLA

619CNX0240E0

208/230-1-60

187

253

07

0.5

92

-

1 0

15

619CNX0360E0

20

1.3

160

-

20

15

619CNX0480E0

3.7

1.0

396

—

1.8

15

619CNX0240W0

07

0.5

2092

2

11.5

20

619CNX0360W0

20

1.3

3160

3

17.9

35

619CNX0480W0

37

1.0

4396

4

22.9

40

LEGEND

FLA

— Full Load Amps

HACR — Heating, Air Conditioning, Refrigeration

LRA

— Locked Rotor Amps

MCA — Minimum Circuit Amps per NEC Section 430-24

NEC

— National Electrical Code

‘Permissible limits of the voltage range at which unit will operate

satisfactorily.

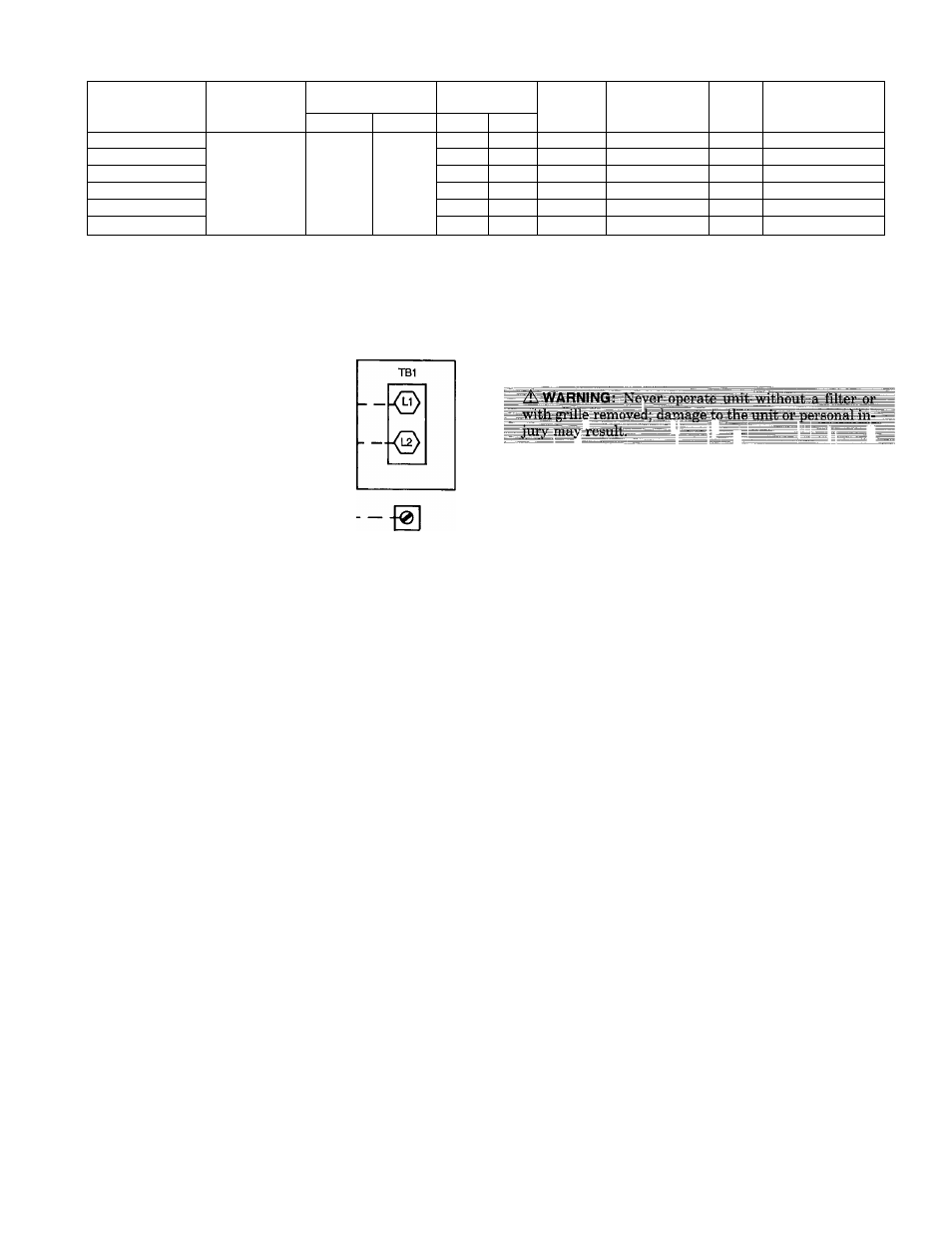

208/230 VOLT

1-PHASE

CONNECTION

TO INDOOR

DISCONNECT

<

START-UP

EQUIPMENT

GROUND

Fig. 16 — Line Power Connections

VIII. CONNECTIONS TO OUTDOOR UNIT

A. Cooling Only Systems

The following connections must be made to the 700C unit for

it to operate as a system with the indoor unit:

1. A thermistor connection cord with a lead length of 35 ft

is shipped with the 619C unit. Run the connection cord

from the condensing unit to the low-voltage terminal strip

on the control board of the fan coil unit. The stripped

end of the connection cord goes to the fan coil end. Use

care to route the wires so that they will not be dam

aged, and do not run them near power wires. Connect

the orange wires to terminals D1 and D2 on the control

board.

2. Route 2 wires of 18-gage thermostat cable between the

low-voltage terminal block of the fan coil and the 700C

unit. Connect the wires Y to blue wire going to high-

pressure switch, and R to R on the low-voltage

transformer.

B. Heat Pump Systems

The following connections must be made to the 705C unit for

it to operate as a system with the indoor unit:

1. A thermistor cord with a lead length of 35 ft is shipped

with the 619C unit. Run this cable from the heat pump

to the low-voltage terminal strip on the control board on

the fan coil unit. Use care to route the wires so that they

will not be damaged, and do not run them near power

wires. Connect the orange wires to terminals D1 and D2

on the terminal strip, and the blue wires to terminals

A1 and A2 on the terminal strip.

2. Route 4 wires of 18-gage thermostat cable between the

low-voltage terminal block of the fan coil and the 705C

unit low-voltage terminal block. Connect Y to Y, O to O,

G to G, and C to C with the wires.

The following checks should be made before system start-up.

Refer to 700C or 705C installation, start-up and service in

structions for system start-up instructions and refrigerant

charging methods.

1. Check condensate drainage system.

a. Remove grille and frame from the unit.

b. On the opposite side of the drain connection, insert a

water bottle up into the fan coil unit and fill drain

pan. Refer to Fig. 18. Water must flow regularly; if

not, check the pipe slope or inspect for any pipe

restrictions.

2. Make sure that all wiring connections are correct and

that they are tight.

3. Check that all barriers, covers, and panels are in place.

Ensure that the filters and return-air grilles have been

installed and that the discharge louvers are positioned

correctly.

I. AFTER EXTENDED SHUTDOWN

If the system has been turned off for more than 12 hours,

turn on the indoor and outdoor unit disconnect switches to

supply power to the system for 12 hours BEFORE starting

the system.

II. SEASONAL CHANGEOVERS

When changing heat pump system from cooling to heating or

heating to cooling, or before starting cooling only system af

ter it has been out of use for the winter season, the following

steps must be performed.

BEFORE starting the system:

1. Inspect and clean the outdoor unit, particularly the coil.

2. Clean or replace the air filters in the indoor unit.

3. Clean the indoor unit drain pan and drain pipe, and re

move any obstructions.

4. Turn on indoor and outdoor unit disconnect switches to

supply power to the system 12 hours before starting the

system.

-

9

-