Bryant PAYNE 619C User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

(SLIDE INSERT)

REINFORCING

BAR«

I WOODEN

HANGING I BRACE

BOLT

REAM

(EDGE

SHARP

“

INSERT)

"‘

embedded

BOLT

(EMBEDDED BOLT

OF PIPING)

WOODEN STRUCTURE

^HANGER BOLT

IL à

NEWLY BUILT CONCRETE SLAB

^EXPANSION

ANCHOR

METAL STRUCTURE

PREVIOUSLY

BUILT CONCRETE SLAB

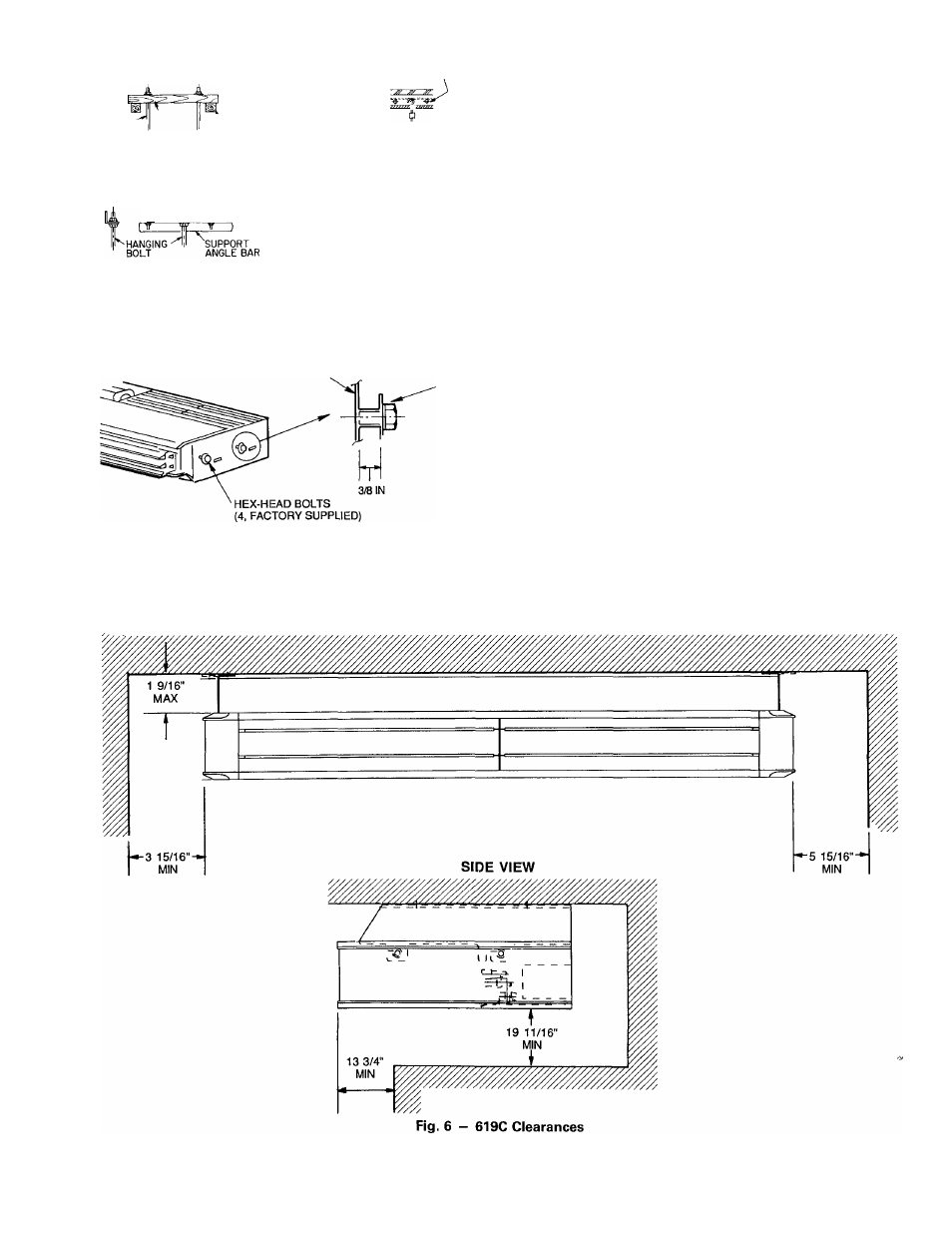

Fig. 4 - 619C Unit-Mounting Methods

(Hardware is Fieid Suppiied)

INDOOR UNIT

BOLT

Fig. 5 - instaliing Hex-Head Mounting Boits

in 619C Unit

e. On heat pump installations check for factory-installed

piston in service valve. If not already installed, in

stall piston in the metering device located in the ser

vice valve on the outdoor unit (Fig. 13). Make sure

Teflon seal on the piston faces toward the outdoor unit.

Use Table 4 to determine required piston size for the

system being installed.

f Refer to 700C and 705C installation, start-up and ser

vice instructions for additional information.

g. Install a liquid line filter drier near the outdoor unit.

On heat pump systems, a bi-flow filter drier must be

used.

3. Insulate and caulk wall openings to reduce air infiltra

tion and refrigerant pipe vibrations on structure.

4. Evacuate piping, if necessary. If either refrigerant pip

ing or the indoor coil is exposed to atmospheric condi

tions for longer than 5 minutes, it must be evacuated to

1000 microns to eliminate contamination and moisture

in the system.

V. CONNECT CONDENSATE DRAIN LINE

Observe all local sanitary codes when installing condensate

drains. Refer to Fig. 3 and 14 for drain hose connection from

indoor unit.

1. Use hard polyvinyl chloride (PVC) pipe material with

nominal ID of 3/4 in. to connect at drain line. Use pipe

insulation 1/4-in. thick, such as Armaflex insulation, on

exposed piping inside the conditioned space.

FRONT VIEW

-

5

-