Bryant PAYNE 619C User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

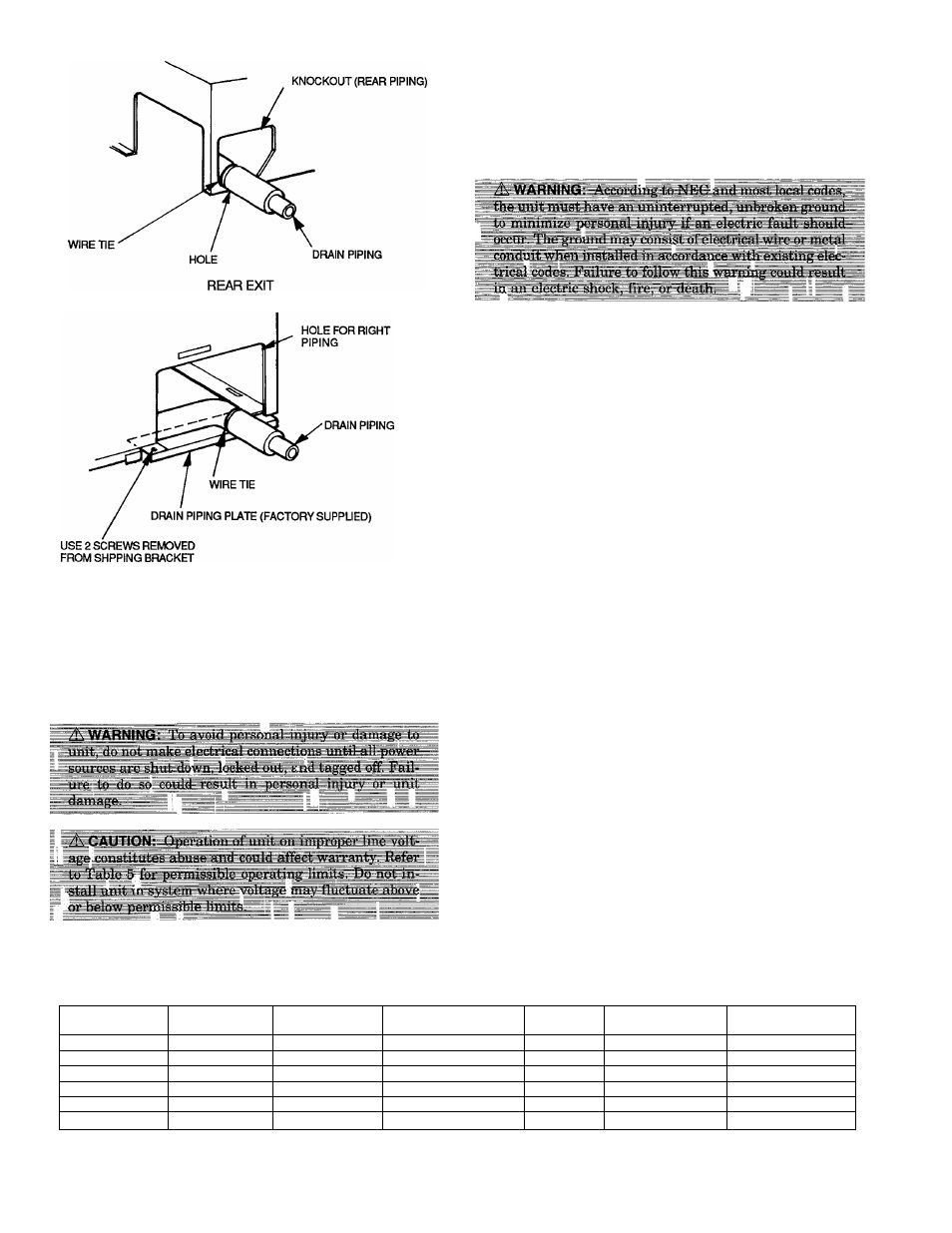

RIGHT-HAND EXIT

Fig. 15 — Routing Drain Piping

VI. MAKE ELECTRICAL CONNECTIONS

Be sure field wiring complies with local building codes and

NEC, and unit voltage is within limits shown in Table 5.

Contact local power company for correction of improper line

voltage.

NOTE;

Install branch circuit disconnect of adequate size to

handle unit starting current per NEC. Locate disconnect within

sight from and readily accessible from unit, per Section 440-14

of NEC. Some codes allow indoor unit to share disconnect with

outdoor unit if disconnect can be locked; check local code be

fore installing in this manner.

1. Route ground and power wires.

NOTE:

Use copper wire only between disconnect switch and

unit.

2. Route line power leads (see Fig. 16) from indoor discon

nect to the fan coil unit. Place wire through hole on the

control box (Fig. 17). Connect wire to high voltage ter

minal board (TB-1) and ground screw. When routing the

wire in the unit, use care to keep the wire away from

refrigerant and condensate piping and any sharp edges.

Units are factory wired for 230 V to 24-V transformer

operation. For 208 V to 24-V operation, interchange blue

(208 V) and red (230 V) wires. Cap unused wires with

wire nuts.

VII. INSTALL CONTROL

The 619C unit is equipped with a microprocessor control which

operates the system. This control is located in the control box

of the fan coil, with thermistors located in the fan coil inlet

and discharge, on the indoor coil, on the outdoor coil, and in

the outdoor-air inlet (heat pump systems only). The ther

mistors monitor system operation and control the operating

mode. To change settings or modes of operation, a wired re

mote controller is supplied.

The factory-preset DIP switches on the 619C control board

set the operation of the unit cooling only or for heat pump

operation. Be sure the switches are set correctly. See wiring

diagram on page 16 or 17, and also the control, service, and

troubleshooting guide (available from your distributor) for more

information.

A. Wired Remote Controller

The wired controller is directly connected to the unit by the

plug connection provided. Standard cable length is 15 ft, but

the cable can be any length up to 200 ft.

Determine where the best location is to mount the controller.

Since the controller is not used to sense the temperature of

the room, locate the controller in a convenient place that is

easily accessible to the user.

The cable can be surface mounted or may be run over ceil

ings and through walls. Follow local codes when installing

low voltage wires.

To install remote controller, see separate remote controller

installation instructions.

Table 4 — Required Piston Size for Check-Flo-Rater™ Metering Device

OUTDOOR UNIT

INDOOR UNIT

INDOOR PISTON

INDOOR PISTON TYPE

OUTDOOR

PISTON

OUTDOOR PISTON

TYPE

REQUIRED SYSTEM

CHARGE * (lb)

700CNX024

619CNX0240E0

55

B

-

A

68

700CNX036

619CNX0360E0

65

B

-

A

6.8

700CNX048

619CNX0480E0

84

B

-

A

too

705CNX024

619CNX0240WO

-

B

~

A

-

705CNX036

619CNX0360W0

-

B

-

A

-

705CNX048

619CNX0480W0

-

B

-

A

-

LEGEND

B - Chatleff

'Charge amount is determined with 25 ft. of iine

-

8

-