Lubrication, Important, Maintenance – Bolens 120-337A User Manual

Page 12: Cutting blade

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

d. Final adjustment of the needle valve

should be slightly to the rich side (turn

counterclockwise) of the mid-point.

3. Move engine control to SLOW. Turn idle ad

justing screw until a fast idle is obtained (1750

R.P.M.).

4. To check adjustment, move engine control

from SLOW to FAST speed. Engine should ac

celerate smoothly. If engine tends to stall or

die out, increase idle speed or readjust car

buretor, usually to a slightly richer mixture.

LUBRICATION

IMPORTANT

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of work

on lawn mower.

Wheels—

Wheel bearings are of self-lubricating For-

tiflex. They require no lubrication.

Engine—

Follow engine manual for lubrication in

structions.

Throttle—

Periodically lubricate throttle control

lever and throttle wire assembly with a few drops

of light oil (SAE No. 10 or 20) for ease of operation.

Chain—

To lubricate the chain, remove the master

link and chain. Soak the chain in kerosene or a sol

vent, and let it air dry. Wipe the chain with a rag

saturated with SAE 30 oil. Reassemble the chain

to the sprockets. Closed end of the master link

clip should face in direction of chain travel.

If the rotary mower is operated in a sandy area, the

chain should not be lubricated. Excessive oil on a

chain will collect dirt and cause excessive wear

on the chain and sprockets.

Discharge Chute Door Mechanism—

The torsion

spring and pivot point should be lubricated

periodically with light oiMo prevent any rust or

binding. Door must work freely.

MAINTENANCE

CUTTING BLADE

The blade may easily be removed for sharpening

or replacement as follows:

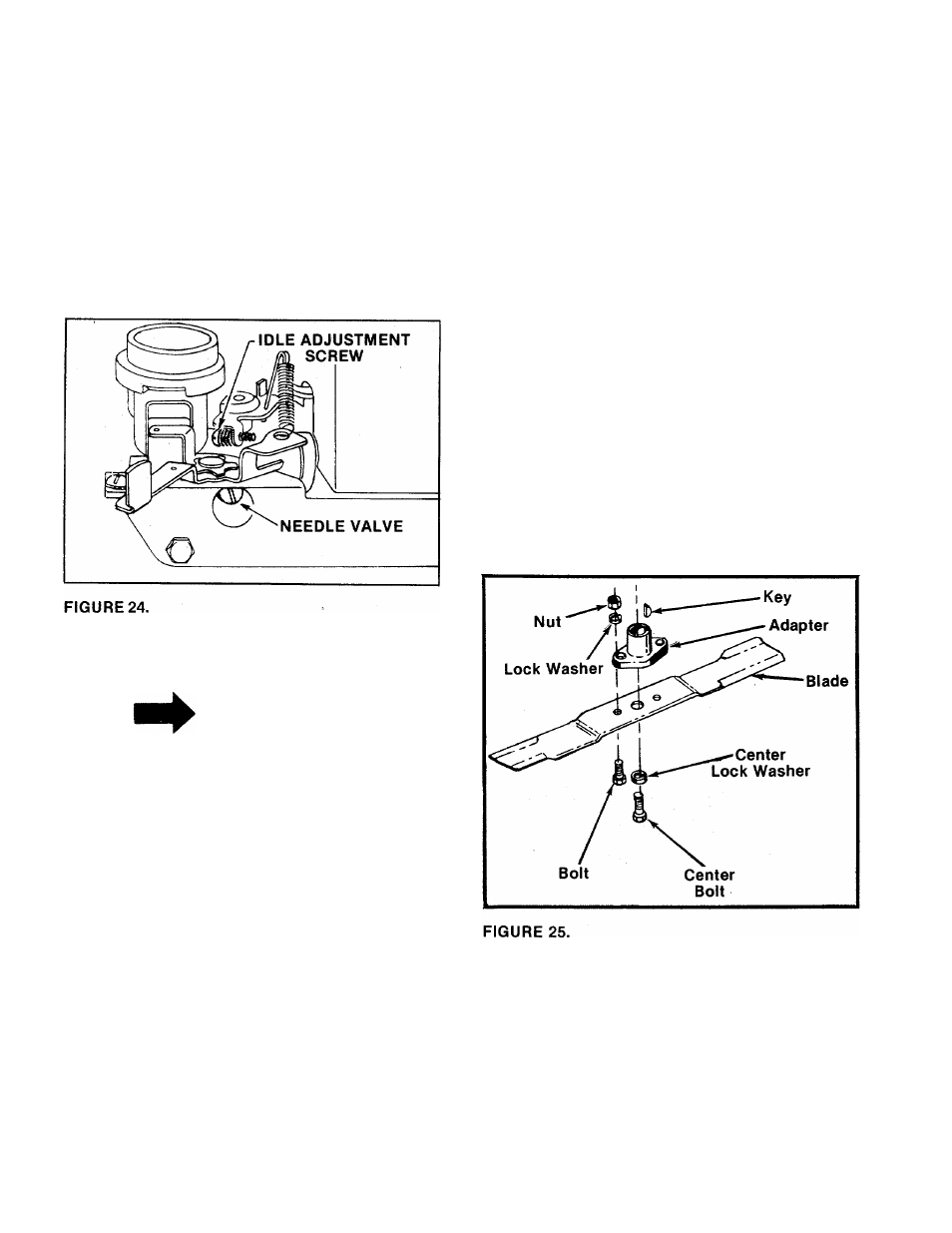

1. Remove the center bolt and center lock

washer holding the blade and adapter to the

engine crankshaft.

2. Remove the blade and adapter from the

crankshaft.

3. Be careful not to lose the key on the

crankshaft. See figure 25.

4. Remove the two smaller bolts, lock washers

and nuts holding the blade to the adapter. See

figure 25.

When sharpening blade, follow the original angle

of grind as a guide. It is extremely important that

each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An un

balanced blade will cause excessive vibration

when rotating at high speeds and may cause

damage to the mower.

The blade can be tested for balance by balancing

it on a screw driver. Remove metal from the heavy

side until it balances evenly. See figure 26.

12