B. external heaters, Ii. ductwork requirements, Iii. wiring – Bryant 559B User Manual

Page 9: A. line-power connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

FAN

HEATER

S

ection

LINE POWER

LEADS

INTERNAL

ELECTRIC

HEATER

CONTROL

-WIRING PLUG

SUPPLY

AIR CONN

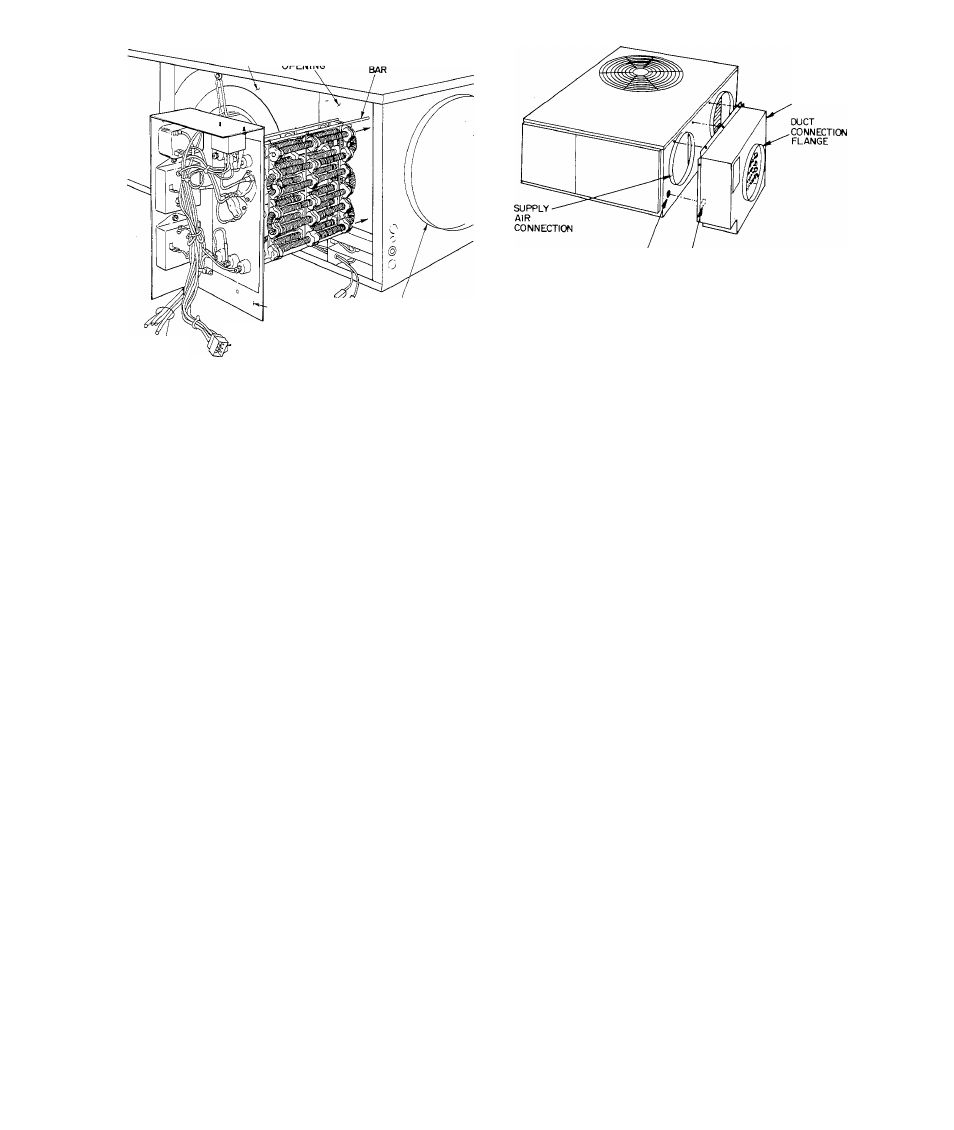

Figure 5—Internal Electric Heater Installation

B. External Heaters

The external heaters are self-locating on the 559B

evaporator fan supply air connection. See Figure 6. Flanges

are provided on the heater for connection to the 559B with

sheet metal screws. See Figure 2. Before installing the

heater, ensure the factory-supplied gasket is in place

around the heater entering air connection as shown in

Figures 2 and 3. Complete installation as follows;

NOTE: When installing external heaters, remove the in

ternal air baffle from the 559B. The external heaters have

their own air baffle.

1. Remove top electrical knockout on 559B. See Figure 6.

2. Place heater over 559B supply air connection. See

Figure 6.

3. Align control wiring hole in entering air side of heater

(Figure 2) with top electrical knockout in 559B. See

Figure 6.

4. Drill holes in 559B to align with screw clearance holes

in heater flanges. See Figure 2 for location of clearance

holes in flanges.

NOTE: Mark the drilling locations while holding the

heater in place against the 559B.

( Al TION: I).. nol pem-lraif drill more iliaii 1 inch iusitlc

5. Fasten heater in place with sheet metal screws.

6. Installation is now ready for electrical connections.

See “Wiring”, Section III.

II. DUCTWORK REQUIREMENTS

Refer to Connecting Ductwork section on page 1 of these

instructions for complete duct installation details. The

following ductwork recommendations pertain to electric

heater applications:

1. Flexible connectors are required between duct con

nection flanges and ductwork to prevent transmission

of vibration. When electric heater is installed, it is

recommended that asbestos (or similar heat-resistant

material) connector be used between ductwork and

heater duct connection flange. If non-heat-resistant

flexible duct is used, it is recommended that a sheet

metal sleeve be inserted inside of duct. Heat-resistant

HEATER

TOP ELECTRICAL KNOCKOUT CONTROL WIRING HOLE

Figure 6—External Heater Installation

duct connector (or sheet metal sleeve) should extend 24

inches from electric heater element.

2. Single-phase external heaters are provided with

means for attachment of circular ductwork only.

Three-phase external heaters are provided with

means for attachment of circular or square ductwork.

3. When electric heater is used, the ductwork must be

capable of handling minimum air quantities shown in

Table III.

III. WIRING

Field wiring must be made in accordance with the National

Electrical Code and local electrical codes governing such

wiring. Provide a separate fused disconnect for each electric

heater circuit. See Table II. Refer to heat package wiring

label.

A. Line-Power Connections

On internal heater installations, bring the line-power

leads from the fused disconnect(s) through the power holes

in the 559B unit panel. Knockouts are provided on the ex

ternal heater cabinet for passage of the line-power leads.

See Figure 3.

Connect the line-power leads to the heater line-power

pigtails or to the heater high-voltage terminal block. See

Figure 10 and Table II for branch circuit data and line-

power connections. Use screw connectors provided for

pigtail connections, and tape each connection. The screw

connectors and terminal block are suitable for copper or

aluminum wire.

If aluminum conductors are used, the wire gauge selected

must have current capacity not less than the copper wire

specifled and must not create a voltage drop between the

service panel and the unit in excess of 2% of the unit rated

voltage.

NOTE: If aluminum conductors are used, the connections

must be made in accordance with the National Electrical

Code. In preparing the wire, just before installing the con

nector, all aluminum wire must be “brush-scratched” and

the wire coated with a corrosion inhibitor, such as Pentrox

A. When it is suspected that the connection will be exposed

to moisture, it is very important to cover the entire con

nection completely to prevent an electro-chemical action

that will cause the connection to fail very quickly. Reducing

the effective size of the wire, such as cutting off strands so

that the wire will fit a connector, is very poor practice.

Proper size connectors should be used.

-

9

-