Vi. maintenance, Cleaning, Table iii — size 024 air delivery performance – Bryant 559B User Manual

Page 6: Table iv — size 030 air delivery performance, Table v — size 036 air delivery performance, Table vi — size 042 air delivery performance, Table vii — size 048 air delivery performance, Vii. instructions to owner

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

VI. MAINTENANCE

Refrigerant Charging

Unit is factory charged. When recharging is necessary, blow

any refrigerant remaining in system, then weigh in total

charge indicated on unit rating plate. Standard 1/4-inch

Schrader service connections are provided on high and

low sides of refrigerant system for evacuation and charging.

Cleaning

Before cleaning, disconnect electrical power.

Condenser Coil: Lift or remove unit top cover for access to

condenser coil. Inspect coil periodically. Clean with brush,

vacuum cleaner, low-pressure water, steam, or air.

Evaporator Coil: Lift or remove unit top cover for access

to evaporator coil. Inspect coil periodically. Clean with

brush, vacuum cleaner, or low-pressure air.

NOTE: When cleaning condenser coil or evaporator coil, be

sure to thoroughly clean out the spaces between fins.

Return Air Filter: Clean filter a minimum of twice yearly.

Flush permanent type with hot water, steam; or soak in

mild solution of soap, or detergent, and water. Allow filters

to dry, and replace. Refer to filter manufacturer’s in

structions, as required, for other types of filters.

This Bryant self-contained cooling unit is designed and in

stalled to provide maximum comfort. Adherence to

following guidelines will help promote greater efficiency

and longer operating life.

1. Do not rapid-cycle unit. Allow at least 3 minutes

before returning unit to operation after shutdown.

On size 048 units, do not manually override

COMPROTEC^.

2. If there is a general power failure, it is recommended

that electrical power supply be turned off at unit

disconnect switch until electrical power supply to

building is restored. This prevents excessive current

draw that would result from momentary low-voltage

conditions at time power is restored.

3. Air filters should be cleaned or replaced regularly to

protect against restricted airflow across cooling coil.

4. Size 048 units incorporate Bryant’s COMPROTEC™

system for compressor protection. If compressor

overloads or hi-pressure switch have cause to function,

COMPROTEC ™ system will hold unit off for approxL

mately 5 minutes. At that time, unit will try to restart.

Should original condition still exist, unit will again

cycle on COMPROTEC™ system.

VII. INSTRUCTIONS TO OWNER

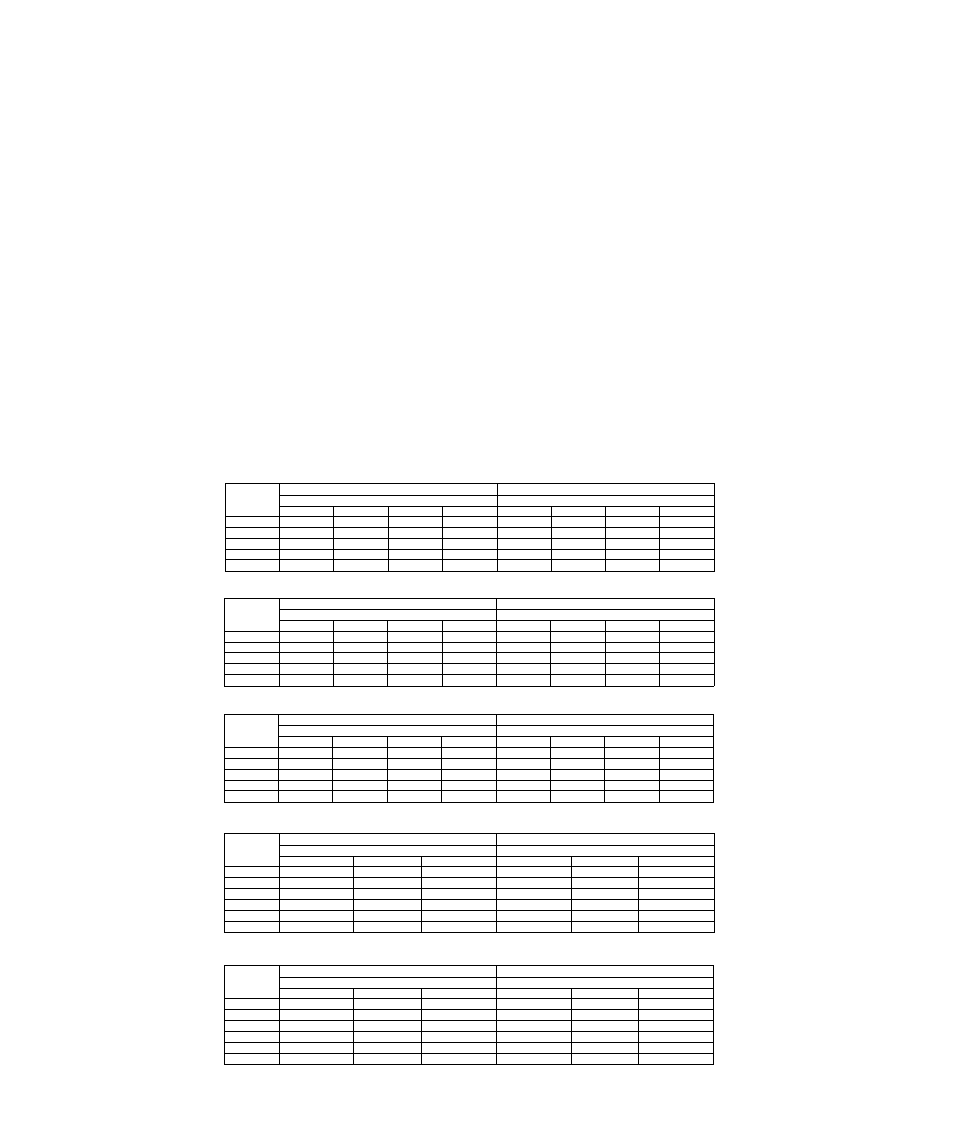

TABLE III — SIZE 024 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

External S tatic Pressure A vailable

External S tatic Pressure A vailable

W et Coil No Filters

Dry Coil No Filters

High

Med

Med Low

Low

High

Med

Med Low

Low

600

0,84

0.80

0.71

0.60

0.86

0.82

0.73

0.62

700

0.76

0.69

0.56

0.25

0.79

0.72

0.59

0.28

800

0,67

0,56

0.38

—

0.71

0.60

0.42

—

900

0,57

0.40

0.14

_

0.62

0.45

0.19

—

1000

0.45

0.17

—

—

0.50

0.22

—

—

TABLE IV — SIZE 030 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

External S tatic Pressure A vailable

External S tatic Pressure A vailable .

W et Coil No Filters

Dry Coil No Filters

High

Med

Med Low

Low

High

Med

Med Low

Low

800

1,12

0.96

0.80

0.21

1.14

0.98

0.82

0.23

900

1,01

0.80

0.48

—

1.04

0.83

0.51

—

1000

0,89

0.61

—

—

0.93

0.65

—

—

1100

0,74

0.37

—

—

0,79

0.42

—

1200

0,56

—

—

—

0,63

—

—

—

TABLE V — SIZE 036 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

External S tatic Pressure A vailable

External S tatic Pressure A vailable

W et Coil No Filters

Dry Coil No Filters

High

Med

Med Low

Low

High

Med

Med Low

Low

1000

1.17

1.10

0,95

0.70

1.21

1.14

0.99

0.74

1100

1.06

0.97

0,77

0.35

1.11

1.02

0.82

0.40

1200

0.95

0.82

0.55

—

1.01

0.88

0.61

—

1300

0.82

0.64

—

—

0,89

0.71

—

—

1400

0.67

0.42

_

0.76

0.51

—

—

TABLE VI — SIZE 042 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

External S tatic Pressure A vailable

External S tatic Pressure A vailable

W et Coil No Filters

Dry Coil No Filters

High

Med

Med Low

High

Med

Med Low

1100

—

—

1.10

—

—

1.14

1200

—

—

0.83

—

—

0.87

1300

—

1.10

0.35

—

1.15

0.40

1400

1.15

0.87

—

1.20

0.91

—

1500

1.00

0.55

—

1.06

0.61

—

1600

0.85

—

—

0.93

—

—

TABLE VII — SIZE 048 AIR DELIVERY PERFORMANCE

Air

Delivery

CFM

External S tatic Pressure A vailable

External S tatic Pressure A vailable

W et Coil No Filters

Dry Coil No Filters

High

Med

Low

High

Med

Low

1400

1.12

0.95

0.60

1.17

1.00

0.65

1500

1.02

0.79

0.25

1.07

0.84

0.30

1600

0.92

0.61

—

0.97

0.66

—

1700

0.80

0.40

—

0.87

0.47

—

1800

0.68

0.15

—

0.76

0.23

—

1900

0.53

—

—

0.64

—

—

-

6

-