Table ii—heater electrical data, B. control wiring (24v), C. thermostat leads – Bryant 559B User Manual

Page 10: Iv. service

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

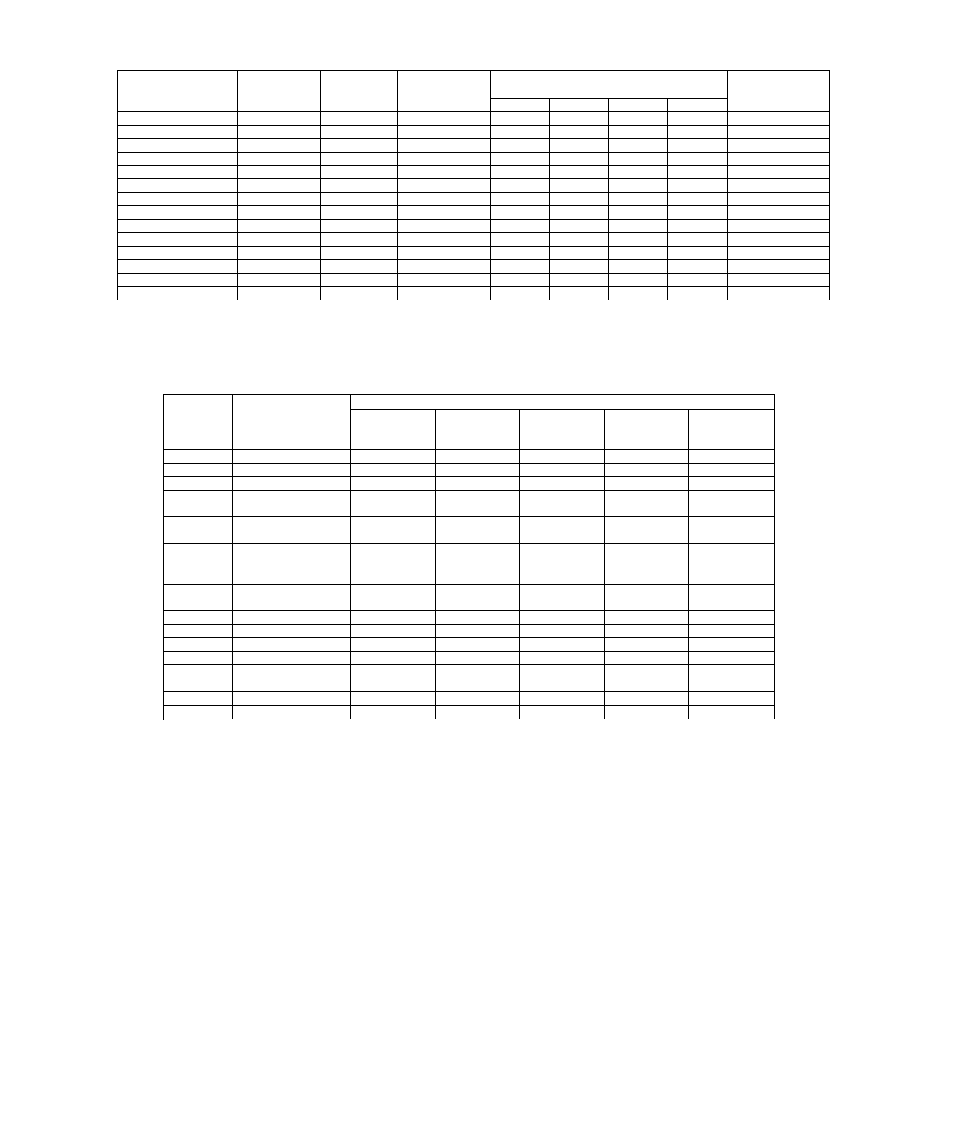

TABLE I—HEATER DATA & USAGE

Heater

Bryant

Voltage-

Hertz-

Btuh Output

Size Unit

Model No.

P/N

KW*

Phase

208V

230V

240V

480V

Used With

88EA0050CA00

7O181D01

5

240-60-1

—

15,673

17,065

—

024, 030, & 036

88EA0075CAOO

7O181D02

7.5

240-60-1

—

23,509

25,598

—

024 thru 048

88EA0100CA00

7O181D03

10

240-60-1

—

31,345

34,130

—

024 thru 048

88EA0150CA00t

7O181D04

15

240-60-1

_

47,018

51,195

—

030 thru 048

88EA12O0CAOOt

7O181D05

20

240-60-1

—

62,690

68,260

—

042 & 048

88EA1250CA00t

70181D06

25

240-60-1

—

78,363

85,325

—

,042 & 048

88EA1250LA00t

7O181D08

25

208-60-3

85,325

—

—

—

042 & 048

88EA0075EA00

7O181D01O

5.6/7.5

208/240-60-3

19,227

23,509

25,598

—

030 thru 048

88EA0100EAOO

7O181D011

7.5/10

208/240-60-3

25,635

31,345

34,130

—

030 thru 048

88EA0145EA00

7O181D012

10.9/14.5

208/240-60-3

37,171

45,450

49,489

—

030 thru 048

88EA1198EAOOt

7O181D013

14.9/19.8

208/240-60-3

50,758

62,063

67,577

—

042 & 048

88EA1250EA00t

7O181D014

18.75/25

208/240-60-3

64,089

78,363

85,325

—

042 & 048

88EA0160FA00

7O181D016

10

480-60-3

—

—

—

34,130

048

88EA1200FA00t

7O181D018

20

480-60-3

—

-

—

68,260

048

*At rated voltage.

tThese heaters are wired for two-stage heating. Remaining heaters are wired for single-stage heating.

NOTE:

The 18.75/25- and 25-KW heaters must be field-connected for two-stage operation. All other heaters wired for two-stage heating

may be field-connected for single- or two-stage operation.

TABLE II—HEATER ELECTRICAL DATA

KW

Voltage-

Hertz-

Phase-

Branch Circuit

No. of

Circuits

FLA

(each)

Wire

Size*

(AWG No.)

Max Wire

Length

(ft)**

Fuse

Amps

5t

240-60-1

1

20.8

10

45

30

7.5t

240-60-1

1

31.2

8

45

40

lot

240-60-1

1

41.7

6

55

50

15t

240-60-1

2

41.7

6

55

50

20.8

10

45

30

20

240-60-1

2

41.7

6

55

50

41.7

6

55

50

25

240-60-1

3

41.7

6

55

50

41.7

6

55

50

20.8

10

45

30

25

208-60-3

2

34.7

6

55

45

34.7

6

55

45

5.6/7.5t

208/240-60-3

1

15.6/18.0

12/10

49/49

20/25

7.5/1 Ot

208/240-60-3

1 ■

20.8/24.0

10/10

59/59

30/30

10.9/14.5t

208/240-60-3

1

30.2/34.9

8/6

63/63

40/45

14.9/19.8

208/240-60-3

1

41.3/47.6

6/4

46/73

60/60

18.75/25

208/240-60-3

2

26.0/30.1

8/8

47/47

35/40

26.0/30.1

8/8

47/47

35/40

lot

480-60-3

1

12.0

14

59

15

20

480-60-3

1

24.0

10

74

30

tThese heaters are internally installed. All others are externally installed.

*Based on 60°C copper wire. If other than 60°C copper conductor is used, determine size from unit ampacity and the

National Electrical Code. Voltage drop of wire must be less than 2% of unit rated voltage.

**Length shown is for one way along the wire path from unit to service panel for minimum voltage drop.

B. Control Wiring (24V)

Between Heater and 559B

A low-voltage control-wiring plug is provided on the heater

for connection to the receptacle in the 559B control-wiring

terminal box.

On internal heater installations, extend the control-wiring

plug through the hole provided in the 559B control-wiring

terminal box and connect to the receptacle. On external

heaters, feed the plug through the control-wiring hole

provided in the heater cabinet (Figures 2 and 6) and into

the 559B. Extend the plug into the 559B control-wiring ter

minal box and connect the plug to the receptacle.

NOTE: When heater installation is completed, be sure to

seal holes around all electrical openings to prevent air

leakage.

C. Thermostat leads

The thermostat leads are brought through the grommeted

hole, provided in the 559B, into the control-wiring terminal

box. Connect the thermostat leads to the low-voltage

pigtails. See Figure 8 or 9 for thermostat connection

diagrams.

Tape

unused pigtails separately. When

aluminum field wire is used, lubricate splices with a

suitable splice compound, and use approved copper-to-

aluminum splice connectors. Set the thermostat heat an

ticipator as described in “Determining Heat Anticipator

Setting”, Section V.

IV. SERVICE

A. Limit Switch

The limit switch provides overtemperature protection. A

switch malfunction prevents the heating elements from

being energized. Replace the limit switch if a malfunction

occurs.

B. Time-Delay Relay

The 14.9- through 25-KW heaters are sequenced. The time-

-

10

-