Adjusting the carburetor, Adjusting valve clearance – Generac Power Systems 0940-1 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CAUTION: Do not overbend the spring clip or the

clip wiil lose its clamping force.

3. With pliers, lightly compress the spring clip on the carbu

retor lever arm. This allows the linkage rod to slide freely

through the clip. While the clip is compressed, rotate the

throttle lever in the appropriate direction to increase or

decrease the gap until there is 0.003 inch (0.08-0.5mm)

clearance (Figure 10).

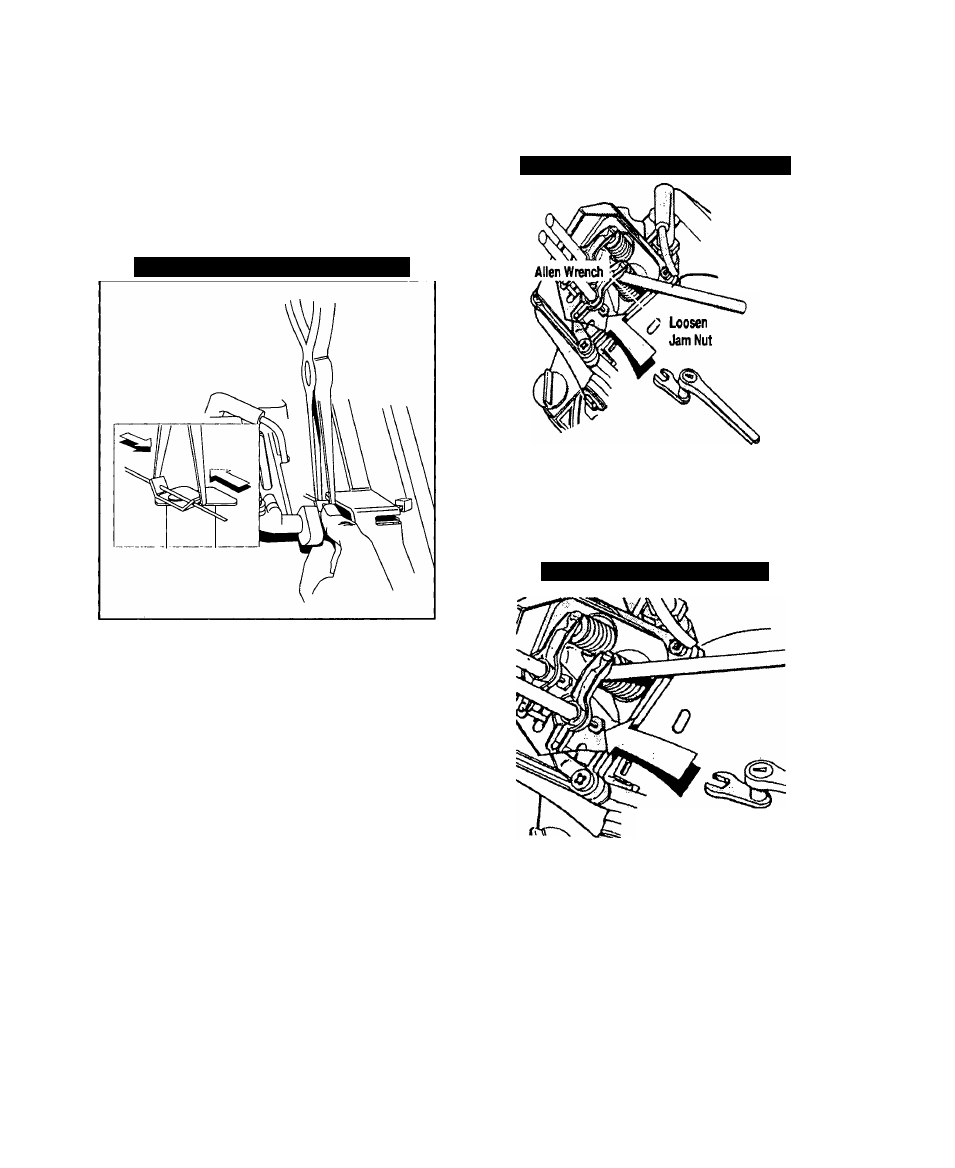

Figure 10 — Adjusting Throttie Linkage

4. Release spring clip so you can secure adjustment. This

allows the carburetor and the electronic governor to be

synchronized.

ADJUSTING THE CARBURETOR

The carburetor of your generator is preset at the fac-

to|

7

. The carburetor should not be tampered with, as

this will void the emission control system warranty. If

your generator is used at altitudes in excess of 5,000

feet, consult your Generac Authorized Service Facility

regarding high altitude jetting changes.

ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should adjust

the valve clearance in the engine.

When adjusting valve clearance, the engine should

be at room temperature and the piston should be at

Top Dead Center (TDC) of its compression stroke

(both valves closed). Correct clearance is 0.001-

0.003 inch (0.03-0.07mm). Adjust valve clearance as

follows:

1. Loosen the rocker arm jam nut. Use an alien wrench to

turn the pivot ball stud while checking clearance between

the rocker arm and the valve stem with a feeler gauge

(Figure 11).

Figure 11 — Adjusting Valve Clearance

Feeler

Guage

2. When valve clearance is correct, hold the pivot ball stud

with the alien wrench and tighten the rocker arm jam nut

with a crows foot. Tighten the jam nut to 65-85 inch-

pounds torque. After tightening the jam nut, recheck valve

clearance to make sure it did not change (Figure 12).

Figure 12 — Tightening Jam Nut

Tighten Jam Nut to

65-85 inch-pounds

(7-10 N-m)

— 1 4 —