Formation of the lock stitch, Practice for beginners – SINGER 404K User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Band Wheel

—the large wheel with a groove in which the belt runs, mounted

on the

band wheel crank

and rotated by the up and down motion of

the pitman.

Belt Shifter

—the lever at the front of the band wheel, which may be turned

to the left to throw the belt off the wheel. The belt may be replaced

automatically

by

treadling,

this

action

being

accomplished

by

a

pro

jection on the side of the band wheel, assisted by the

belt guide

in

the rear.

Legs

—the upright members which support the table.

Dress Guard

—the shield in front of the band wheel protecting the operator’s

clothing.

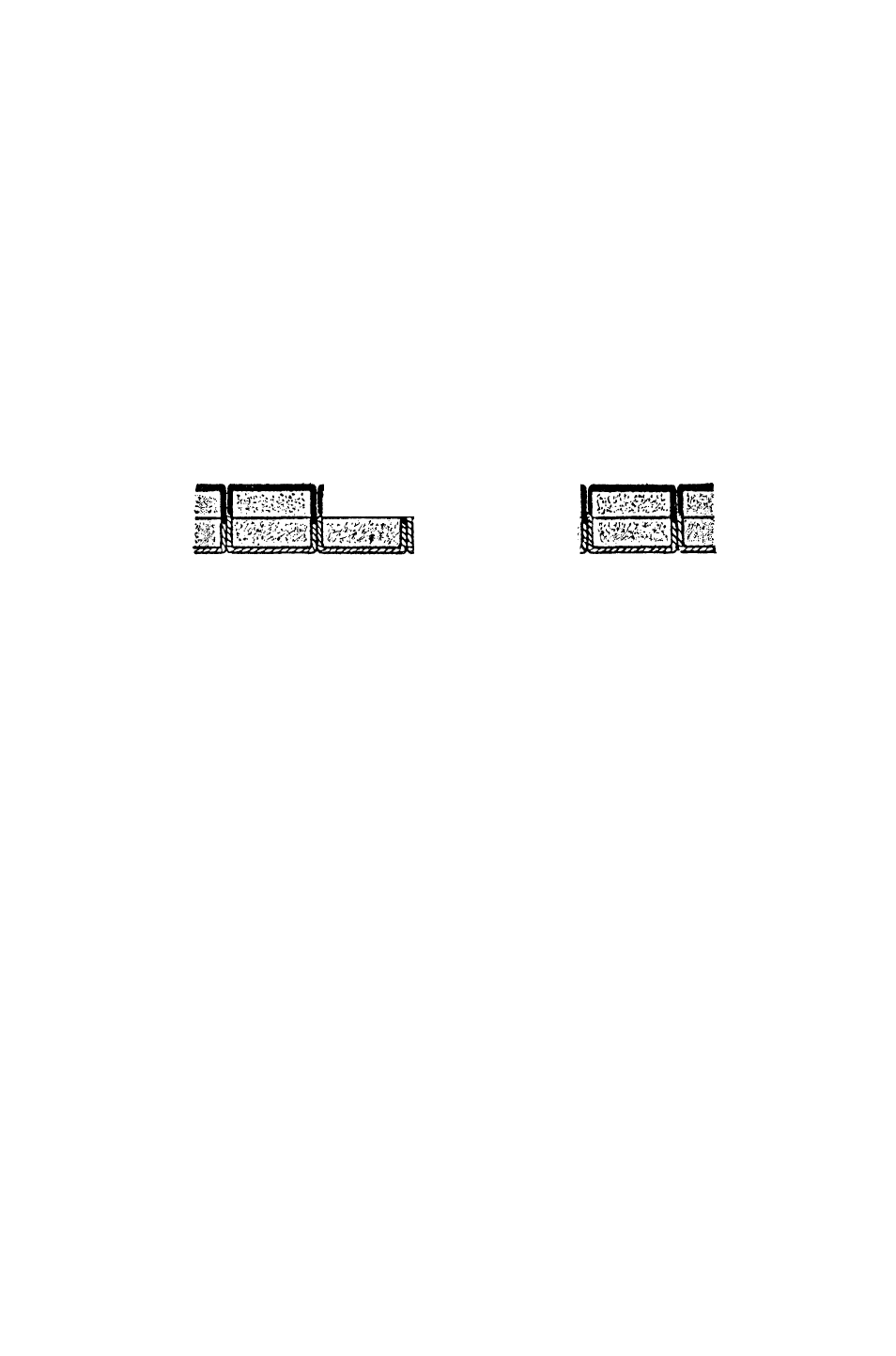

Formation of the Lock Stitch.

The lock stitch made by sewing machines consists of an upper or needle

thread and an under or bobbin thread locked together in the material which is

being stitched, the lock being formed by passing the upper around the lower

thread and tightening them together in the middle of the fabric.

^sxBBXzrea

F

ig

. 3.

When a stitch has been completed and before each succeeding stitch is

commenced, the fabric being stitched is carried from the needle by the feeding

mechanism, and upon the length of its movement depends the length of the

stitch.

The presser foot rests upon the fabric, prevents it from rising with the

needle and holds it in contact with the feed dog while the feeding takes place.

The section of the foot which presses on the cloth is slotted so that the view

of the stitching may not be obstructed.

PRACTICE for BEGINNERS

The

beginner

should

acquire

a

knowledge

of

the

various

parts

of

the

sewing machine and the purpose of each, in order to give the machine proper

care

and

to

obtain

the

best

results

from

it.

It

is

essential

that

practice

precede actual sewing on the machine. For this practice the upper thread and

bobbin should be removed from the machine and the presser foot raised. The

operator should be equipped with a chair high enough to allow her to sit

comfortably and squarely in front of the machine directly in line with the

needle.

Whether the machine is electric or treadle controlled it is essential that the

operator

should

continue

practising

until

she

is

able

to

start

smoothly

and

have an easy control at varying speeds.

Electric Machine.

See that the foot control is placed in such a position

on the floor that the foot can rest comfortably on it. Press lightly on the

control knob with the toe to test the amount of pressure needed for varying

speeds before threading up and starting to sew.

Treadle

Machine.

The

operator

should

sit

squarely

in

front

of

the

machine

with

the

feet

placed

comfortably

on

the

treadle.

The

right

foot

should be placed forward and the left backward so that the pressure on the

treadle is with the ball of the foot.