Gleaning and oiling—(continued) – SINGER 404K User Manual

Page 25

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Gleaning and Oiling—(Continued)

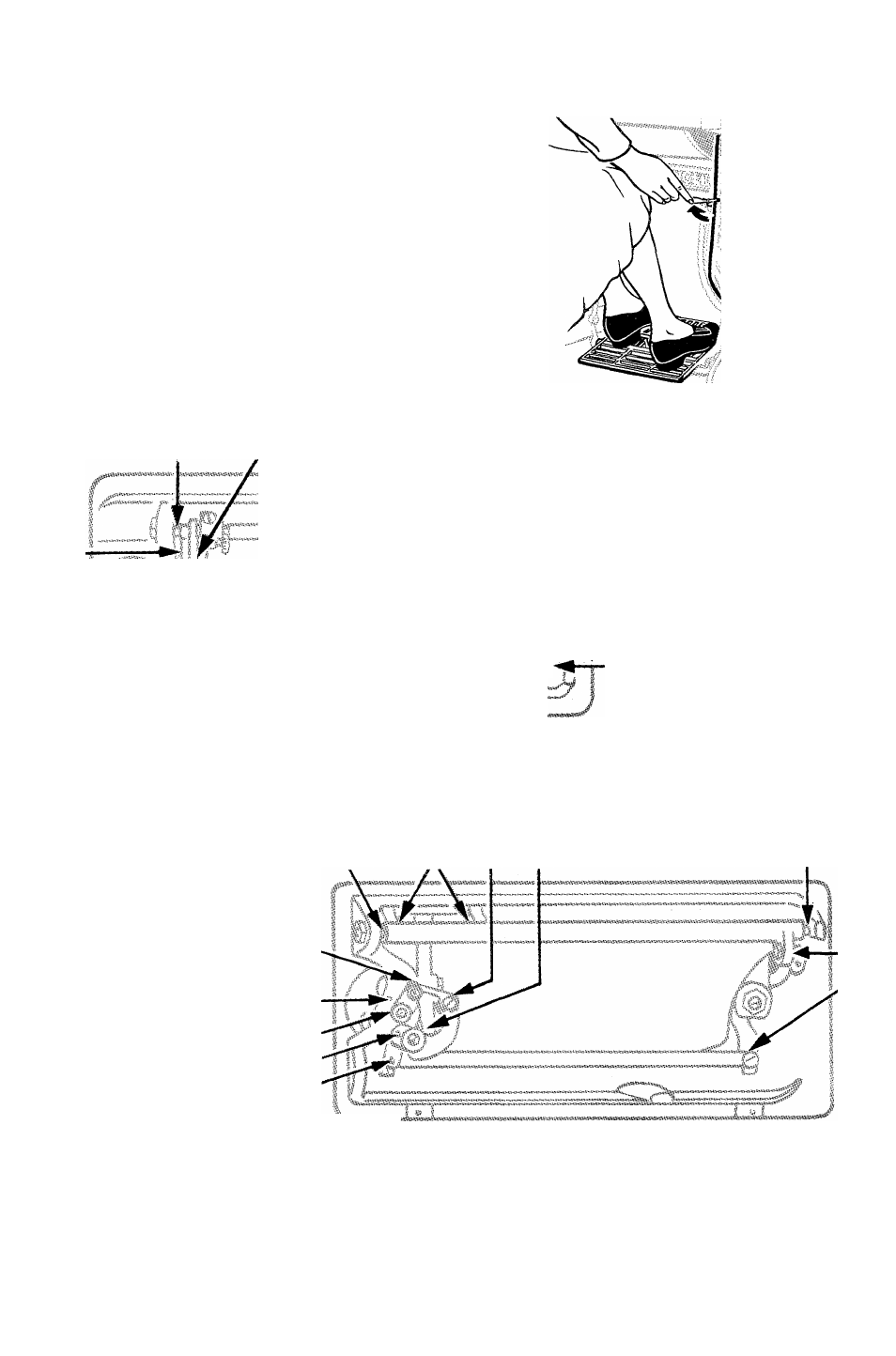

The

face

plate

should

also

be

removed

to give access to the oiling points on the

needle

bar,

presser

bar

and

thread

take-up.

Apply a drop of oil to each oil hole and joint.

Release

the

belt

from

the

band

wheel

by moving the lever of the belt shifter, Fig.

49, to the left while the machine is running.

To replace the belt, work the treadle slowly

with

the

band

wheel

turning

towards

you.

The belt will then be automatically brought

back into place. Do not throw the belt off

to the left side of the band wheel, as it is

difficult to replace it from that side.

F

ig

.

49.

T

he

B

elt

S

hifter

.

I?

it /1

F

ig

.

50.

O

iling

P

oints

below

B

ed

of

M

achin e

201K.

After releasing the

^ A

I belt, turn the head of

Li

I the machine back on

its hinges in order to

reach the oiling points

on its under side. By

turning

the

hand

wheel slowly you will

be able to observe all

working

parts.

It

is

sufficient

to

apply

a

drop of oil only at each

point of contact. After

oiling all points on the

under side, lower the

machine into sewing position and oil each point on top. Wipe away surplus

oil and run the machine rapidly for a few minutes so that the oil may penetrate

to

the

bearings.

The

machine

should

then

be threaded and a few

stitches

made

in

a

waste piece of material

so that any excess oil

may be removed.-

When

a

machine

is

used

and

cleaned

frequently,

it

is

not

necessary

to

remove

the

throat

plate,

slide

and bobbin each time,

but

this

should

be

done

occasionally

in

in

order

to

remove

lint and dust.

'SHUilti-lIHUriiUliiliiirJttUi

F

ig

.

51.

O

iling

P

oints

below

B

ed

of

M

achin e

66K.

25