SINGER 6136 User Manual

Page 25

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

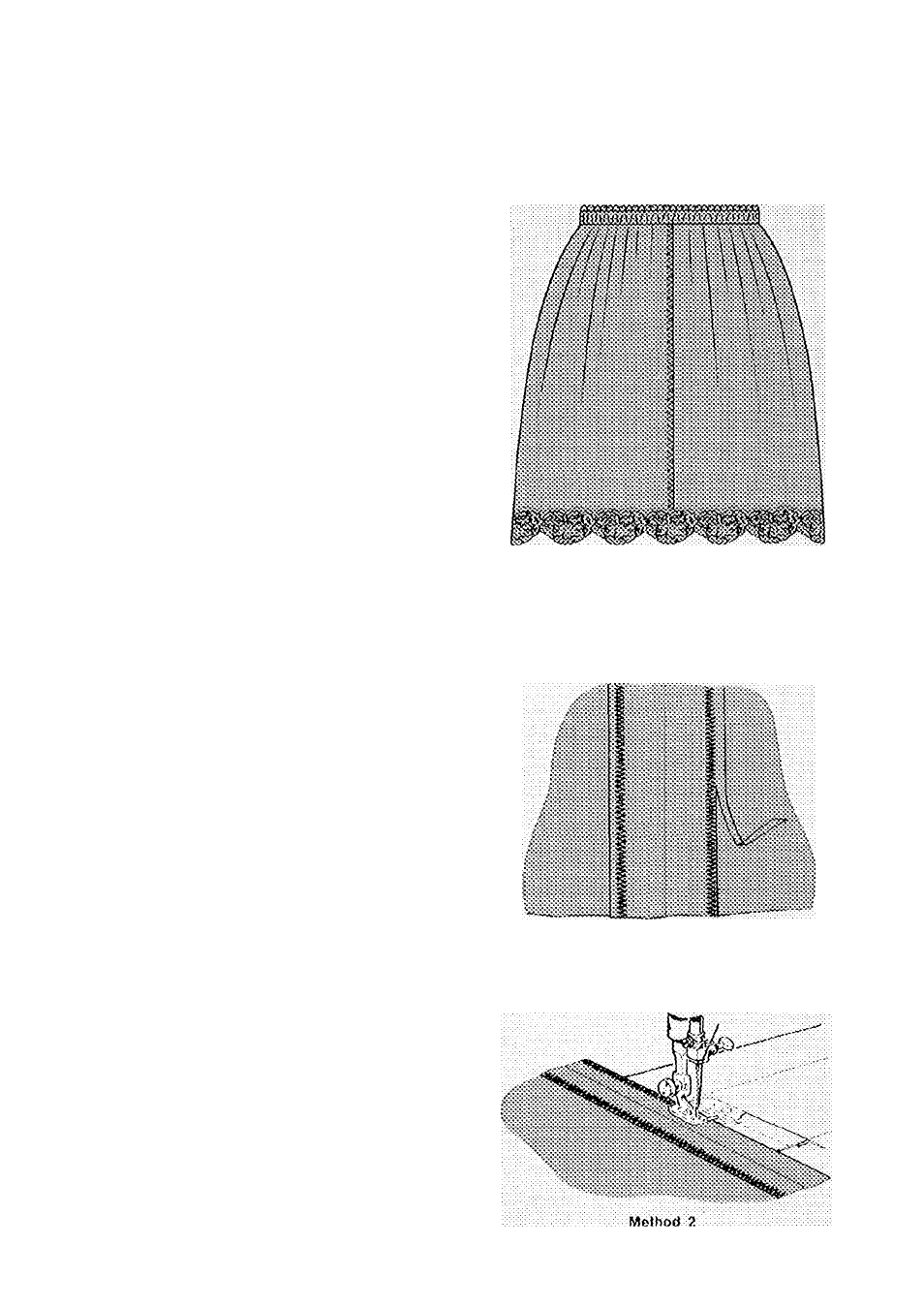

LINGERIE vSEAMS

To make a lingetio soam durable and flexible use the plain xig-/.ag stitch at a narrow width

setting. This seam treatment is particularly suitable for bias seams. When seaming nylon tricot

insert a 2045 needle in the machine before you begin to sew.

• Straight stitch the soam tine on wrong side

of fabric.

• Press both seam allowances in the same

direction.

• From the right side, topstitch with narrow

7.\g~7MQ stitching, letting the needle alter

nately enter the seam lino and seam thick

ness.

(Stitch width narrow; stitch length 1 to 1.5).

ZIG-ZAG SEAM FINISHES

Seam edges support the garment and should be given a durable finish it the fat)ric is likely to

ravel, '(here are two methods of finishing seams in such fabrics; irimmirig seam ocige or over-

edging. Make a tost sample to determine which method best suits your fabric.

• PaUem Group Selector: /

• Needle f^osilion; L

9 Stitch Width: j { |i| f ^

• Stitch Length:

1

to 3 to suit fabric

• (ionoral Purpose Needle Plate

• General Purpose Loot

Method 1 - Trimmed Seam Finish

• Adjust stitch width at'ici iengUt to give you

the most -‘Open» stitch that will secure the

fabric edge: avoid harsh overstitching.

•

• Stitch near the edge of scant allowance, and

trim seam edges overtly after stitci^ing.

Method

2

- Overedged Soam Finish

• Adjust ooiKlie ittroad t(?nsion. stitch width,

artd stitch length to suit fabric.

• Trim seam edges evenly.

• fdac(? trimmed seam under the foot and ovm-

edge the seam allowance as illustrated.

Method 1